UFC 4-159-03

3 October 2005

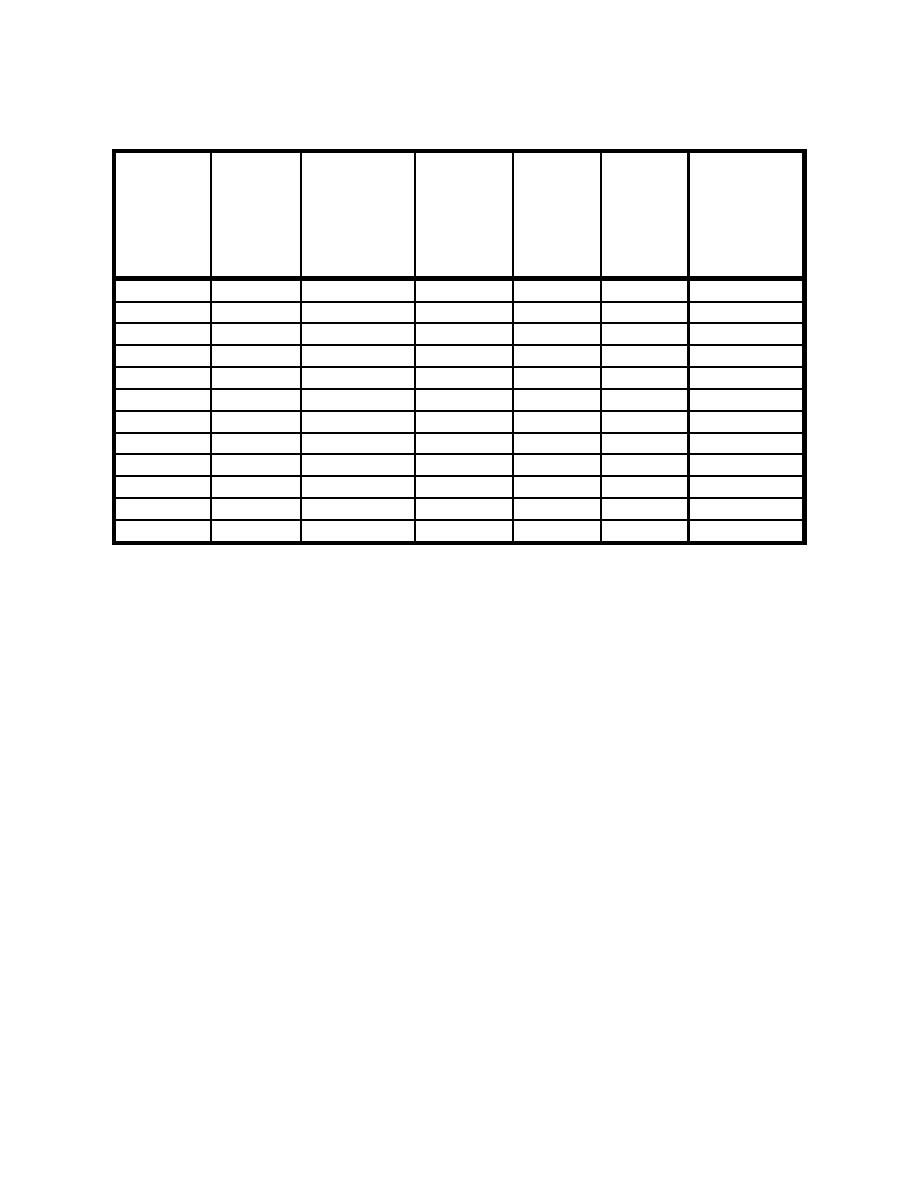

Table 6-7. Stretch of Synthetic Lines

WIRE

DOUBLE

DOUBLE

ROPE & 12-STRAND KEVLAR

BRAIDED

NYLON

BRAIDED

STEEL

HMWPE

4-

POLY-

8-

NYLON

% Break

CORE

STRAND

ESTER

STRAND

Strength

% Stretch % Stretch

% Stretch

% Stretch

% Stretch % Stretch

(T/Tb)

(1)

(2)

(3)

(4)

(5)

(6)

0

0.000

0.000

0.000

0.000

0.000

0.000

5

0.076

0.697

1.922

10

0.151

0.250

1.084

1.275

3.335

4.250

20

0.302

0.434

1.656

2.863

5.798

7.353

30

0.453

0.691

2.025

5.776

7.886

9.821

40

0.605

0.915

7.890

10.210

11.950

50

0.756

1.126

2.495

9.528

11.987

13.610

60

0.907

1.395

11.012

13.745

14.999

70

1.058

1.593

12.338

15.472

80

1.850

13.793

90

2.126

15.054

100

2.356

16.197

(1) From Tension Technology, Inc.

(2) High Molecular Weight Polyethylene; Sampson Ropes

(3) VETS 198 Rope; Whitehill Mfg.

(4) Double Braided; Sampson Ropes; Mean of 10 & 11 in. cir. Data "2-in-1

Stable Braid"

(5) Broken in line; from Tension Technology, Inc.

(6) Double Braided; Sampson Ropes; Mean of 7, 10 & 12 in cir. Data; "2-in-2

Super Strong"

126

Previous Page

Previous Page