TM 5-848-1/AFM 88-12, Chap.1

formulas, demand is usually expressed in cubic feet

well. Consideration must, however, be given to dif-

per hour. Because of the variability of the volume

ferences in inside diameter. In the larger pipe sizes,

of gas with changes in pressure and temperature,

plastic pipe wall thicknesses are likely to be greater

reference to definite bases of pressure and

than those of steel pipe.

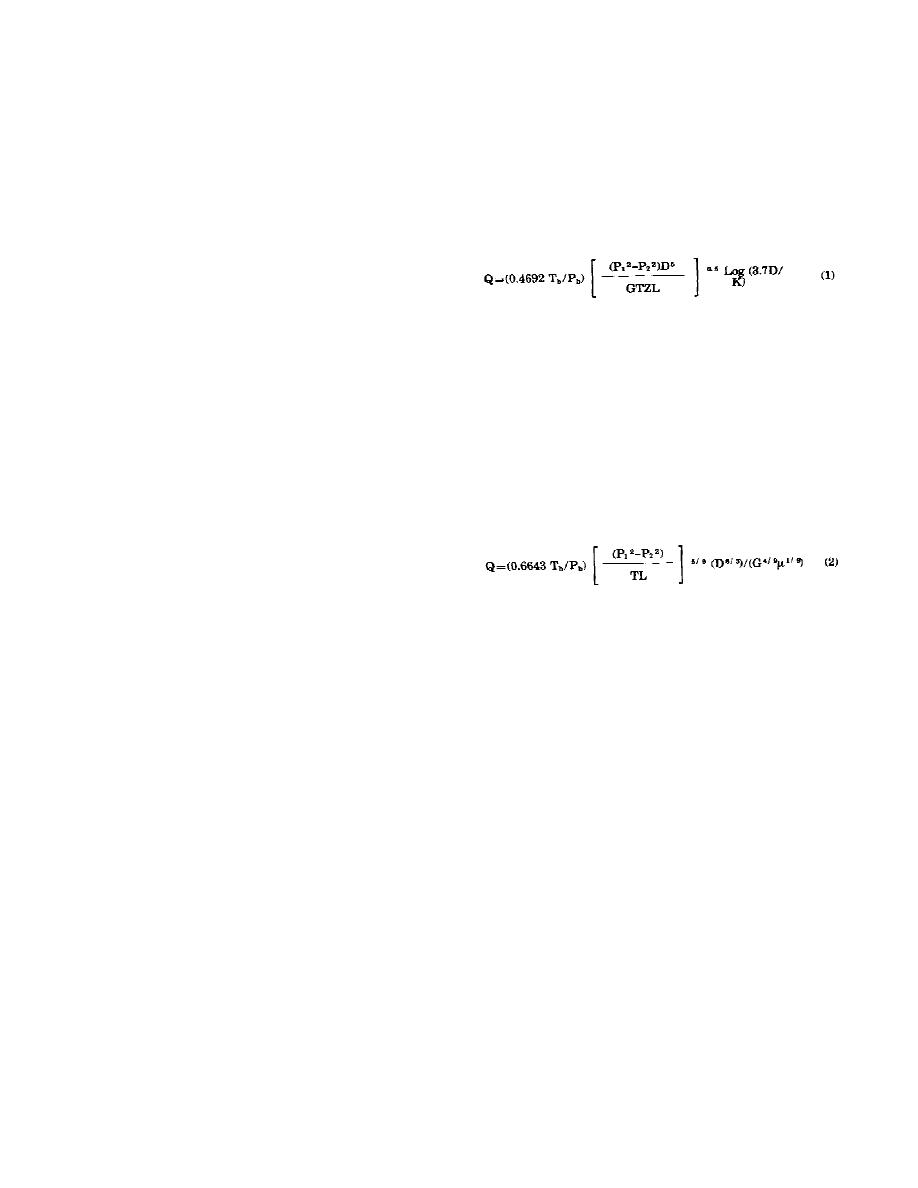

e. Distribution system flow equations.

temperature is necessary in expressing quantities

(1) Fully turbulent flow (rough pipe flow law).

volumetrically. It is essential that the stated

characteristics of the gas, the computations of the

The equation for fully turbulent flow is as follows:

connected appliance loads, and the flow formulas

used in the design of the pipe system, all be on the

same basis. Base conditions are 60 degrees F and

14.73 psia in accordance with AGA Orifice Meter-

ing of Natural Gas, Report No.3.

b. Flow conditions. There is a pressure loss in

(2) Partially turbulent flow (smooth pipe flow

pipes roughly proportional to the square of the ve-

law). Any of the accepted gas flow equations used

locity; and there are at least two distinct flow re-

gimes in pipes, laminar, and turbulent. There is a

with steel pipe, such as Mueller, Pole, or the IGT

distinct discontinuity in behavior of fluid when

Distribution Equation, can also be used for calcula-

laminar flow rates are exceeded, and a large region

tion of plastic pipe flow capacities. Those equations

for mixed flow behavior (partially turbulent flow)

which yield conservative values for steel pipe will

exists between the upper limit of laminar flow and

also be conservative for plastics. The IGT Distribu-

the behavior of pipes in fully developed turbulent

tion Equation is thought to be representative of

flow. The exact transition regions between the

both steel and plastic for most distribution design

various flow regimes are not yet accurately

situations. It is as follows:

predictable for the various fuel gas piping situations

of practical importance. Gas engineering practice

has developed practical approximations at working

around this inadequately defined area. In only very

unusual situations is this lack of exactness of any

practical or economic importance.

c. Distribution system design criteria. The dis-

(3) Definition of terms. The terms used in the

tribution system design engineer rarely designs a

flow equations above are:

totally new system. The design will generally con-

D = inside pipe diameter, inches

sist of changes to an existing system. Even a new

G = specific gravity

system, unless it is for a complete camp, base or

L = length of pipe section, feet

other military facility, has unpredictable loads. The

Pb=base pressure, 14.73 psia

most compelling problem for the distribution

P1 = upstream pressure, psia

system designer is the infrequency of the system

P2 = downstream pressure, psia

operation at or near design capacity.

Q = gas flow rate, MSCFH (thousands of

d. Flow of natural gas in pipelines. Plastic pipe

standard cubic feet per hour)

has a very smooth and slippery surface. Its fric-

Tb=base temperature, 520 Rankine

tional resistance is considerably less than that of

steel pipe. Therefore, it is often assumed that plas-

T = average temperature of flowing fluid,

tic pipe has significantly more flow capacity than

Rankine

steel pipe. This assumption would be correct under

Z = average compressibility factor

fully turbulent flow conditions, such as those en-

= viscosity, lb/ft-sec

countered in water service. However, investigation

K = effective roughness of pipe surface,

of flows in natural gas distribution systems indi-

inches

cates that the design flows usually fall within the

= 0.00006 inch for plastic

range of only partially turbulent flow (see table 1

= 0.0007 inch for steel

for an indication of the typical flow rates in gas

= 0.01 inch for cast iron

distribution systems). In this range, the smooth-

(4) Using the flow formulas. Figure 1 may be

pipe flow equations apply all the time to both plas-

used to determine whether the rough pipe or

tic and steel; therefore, the pipe wall roughness is

smooth pipe flow law should be used. If the flow

not a significant factor. Flow formulas found to be

rate expected is above the curve, then the rough

satisfactory for sizing steel pipe in natural gas

pipe law should be used. If flow rate falls below the

service are recommended for sizing plastic pipe as

7

Previous Page

Previous Page