UFC 3-430-07

24 July 2003

including Change 1, Jan 2004 and Change 2, March 2005

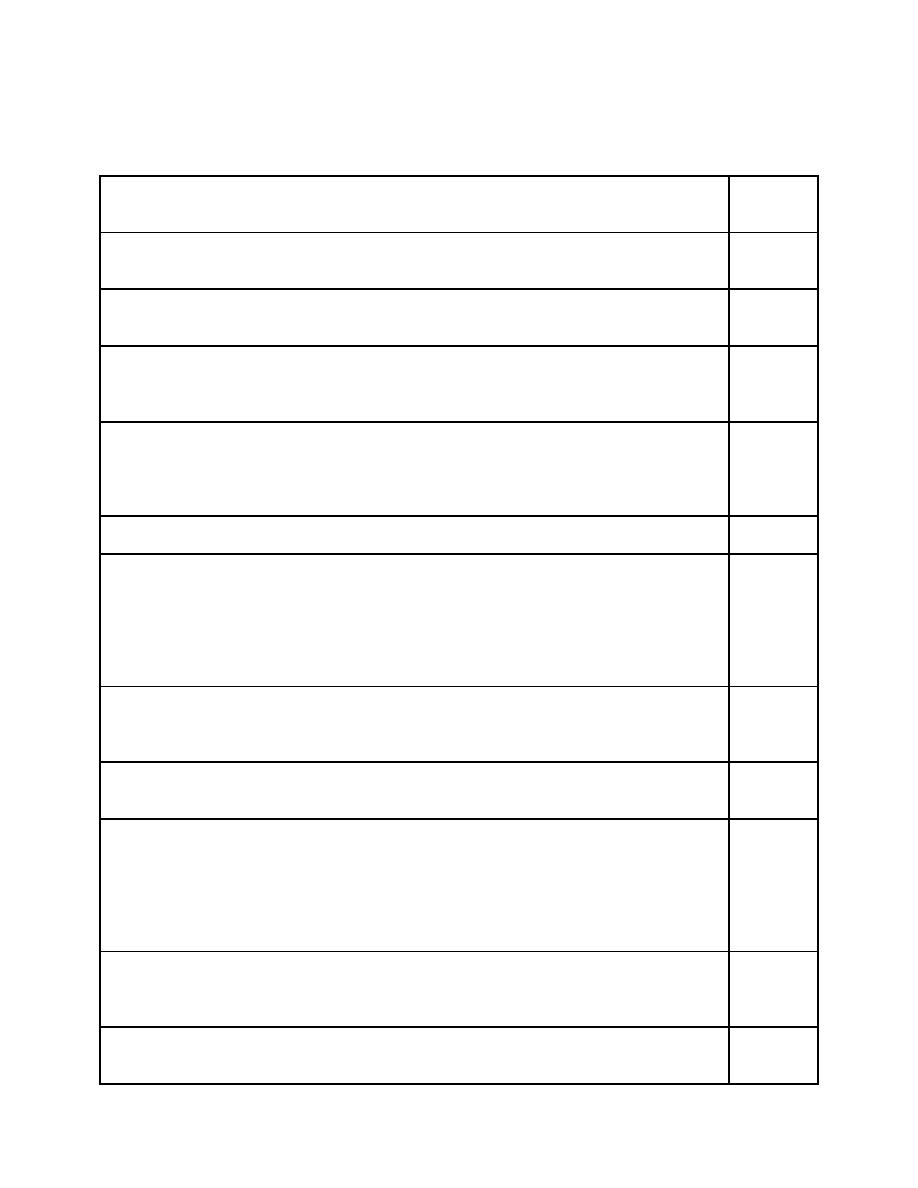

Table F-2 Hot Water Boilers PMI Checklist

1. Observe condition of flame. Correct if flame is smoky or if burner starts with a

Weekly

puff. Flame should not impinge on the furnace walls.

2. Check fuel supply (oil). Note level of oil in tank. Leaking tanks must be repaired

Weekly

or replaced immediately.

3. Observe operation of circulating pumps. Lubricate pump motor, bearing

Weekly

assembly, and flex coupling. Noisy pump motors require repair or replacement.

4. Test flame detection devices and associated automatic fuel cutoff valves. Loss

Monthly

of flame should shut off flow of fuel to the burner(s). Replace or repair if devices or

valves are found defective.

Monthly

5. Inspect fuel supply systems and piping in boilers for leaks, loss of insulation, etc.

Repair or replace as needed. Replace cartridges for in-line oil filters. Adjust oil

pressure as prescribed by the manufacturer. Ensure both oil supply and return

lines have a fusible in-line valve.

6. Check boiler room drains for proper functioning.

Monthly

Monthly

7. Check condition of safety relief valves. Test valve with tri-lever. Valves should

preferably be the pressure and temperature type. Leaking safety valves must be

replaced. No obstructions such as another valve, long pipe length, or constriction

are permissible between the boiler and the safety valve. The overflow from the

valve should be free of obstructions and piped to within 4 inches of the floor or to a

floor drain.

8. Inspect burner assembly. Evidence of improper fuel nozzle wear, plugging, or

Monthly

carbon buildup on the nozzle is cause for replacement. Adjust equipment for proper

combustion after replacing the old nozzle with a new one.

9. Inspect burner assembly. Replace nozzle and filters on oil burning equipment.

Annually

Clean, check, and adjust electrodes.

Annually

10. Inspect internal and external heating surfaces after cleaning. Fireside surfaces

should be free of soot. Cracked surfaces will require repair or replacement of the

furnace (firing chamber). Repair to pressure parts requires a certified welder.

Evidence of bulges or other deformities indicates defective controls and safety

devices or improperly sized and adjusted burner. Consult a boiler water treatment

specialist if there is evidence of hard scale on the waterside surfaces

11. Inspect gas piping and valves regularly for proper support and tightness. Test

Annually

for tightness with a soap solution, never a flame. If a leak is detected, then secure

piping to the boiler and contact the gas company.

12. Check transformer. Do not interchange transformers of different capacities

Annually

when replacing defective transformers.

49

Previous Page

Previous Page