UFC 3-460-03

21 JANUARY 2003

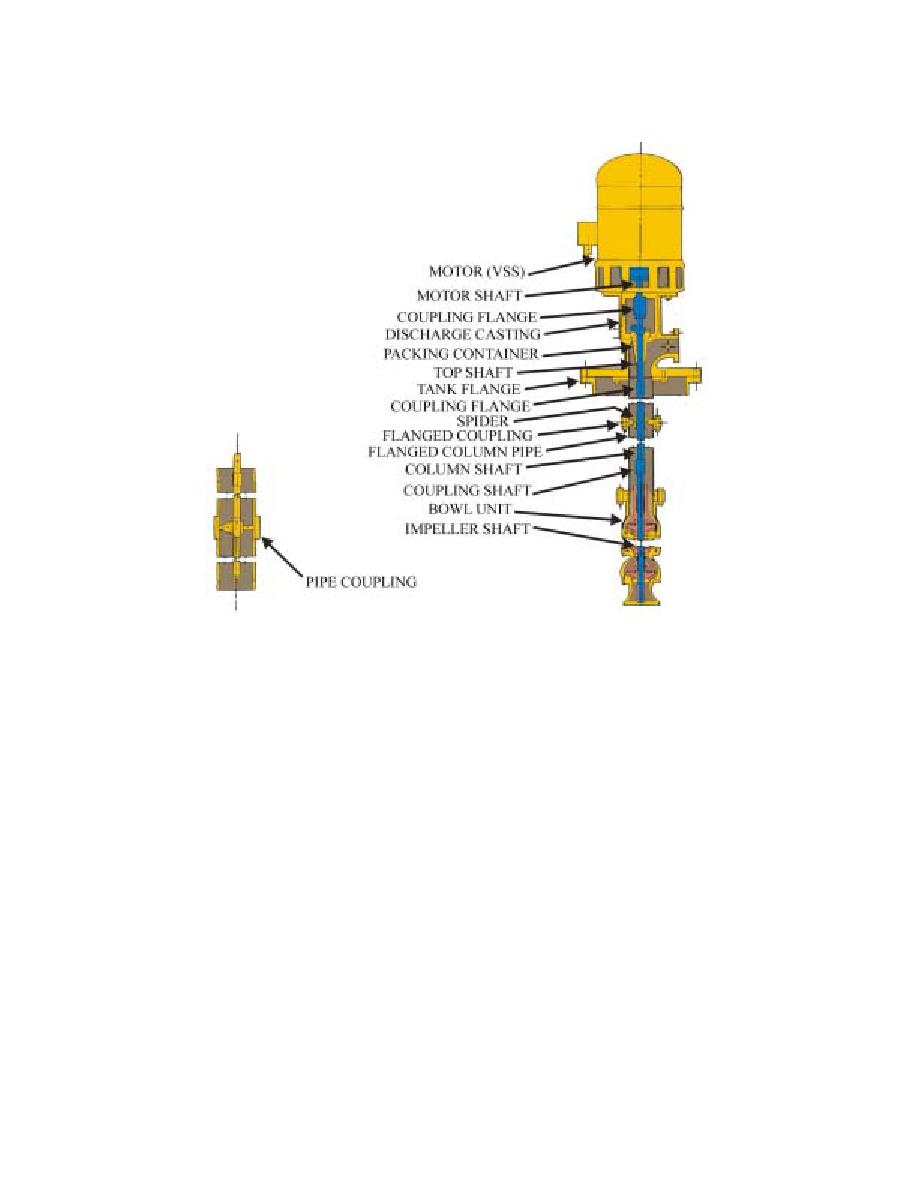

Figure 3.3. Vertical Deepwell Turbine Pump.

3.2.3. For new pump installations, use API Std 610, Centrifugal Pumps for Petroleum, Heavy Duty

Chemical, and Gas Industry Service, centrifugal pumps and vertical turbine pumps. Contact your

MAJCOM fuels engineer for additional information as there are many types and configurations of

API Std 610 pumps. Figures 3.2 and 3.3 show two types of pumps used as transfer pumps.

3.2.4. A hydraulic gradient (Figure 3.4) is usually used in the design of a pumping and piping system

to help in properly sizing lines and selecting pumps to deliver a given amount of fuel in a certain

time. An example of a hydraulic gradient for a given system is shown in Figure 3.4. In this sample,

fuel is pumped from an aboveground storage tank to two truck fill stands simultaneously, at the rate

of 946 liters per minute (250 gallons per minute) to each. The centerline of the tank outlet is

0.91 meter (3 feet) above the eye of the pump. Minimum desirable elevation of the liquid is taken as

the line friction loss of 4.22 meters (13.84 feet) to the elevation of the pump, or 2.13 meters (7 feet).

The pump raises the head to 18.29 meters (60 feet). The friction loss in the 102-millimeter line to the

connection to the two fill stands drops the elevation to 14.31 meters (46.98 feet). The drop at

946 liters per minute (250 gallons per minute) in each piping system to the truck fill stands drops the

elevation to 12.16 meters (39.9 feet). The elevation of the truck fill stand is 7.01 meters (23 feet).

The difference in head (12.16 meters 7.01 meters = 5.15 meters [16.9 feet]) is the head available

for delivering fuel.

19

Previous Page

Previous Page