UFC 3-530-01

22 August 2006

APPENDIX D

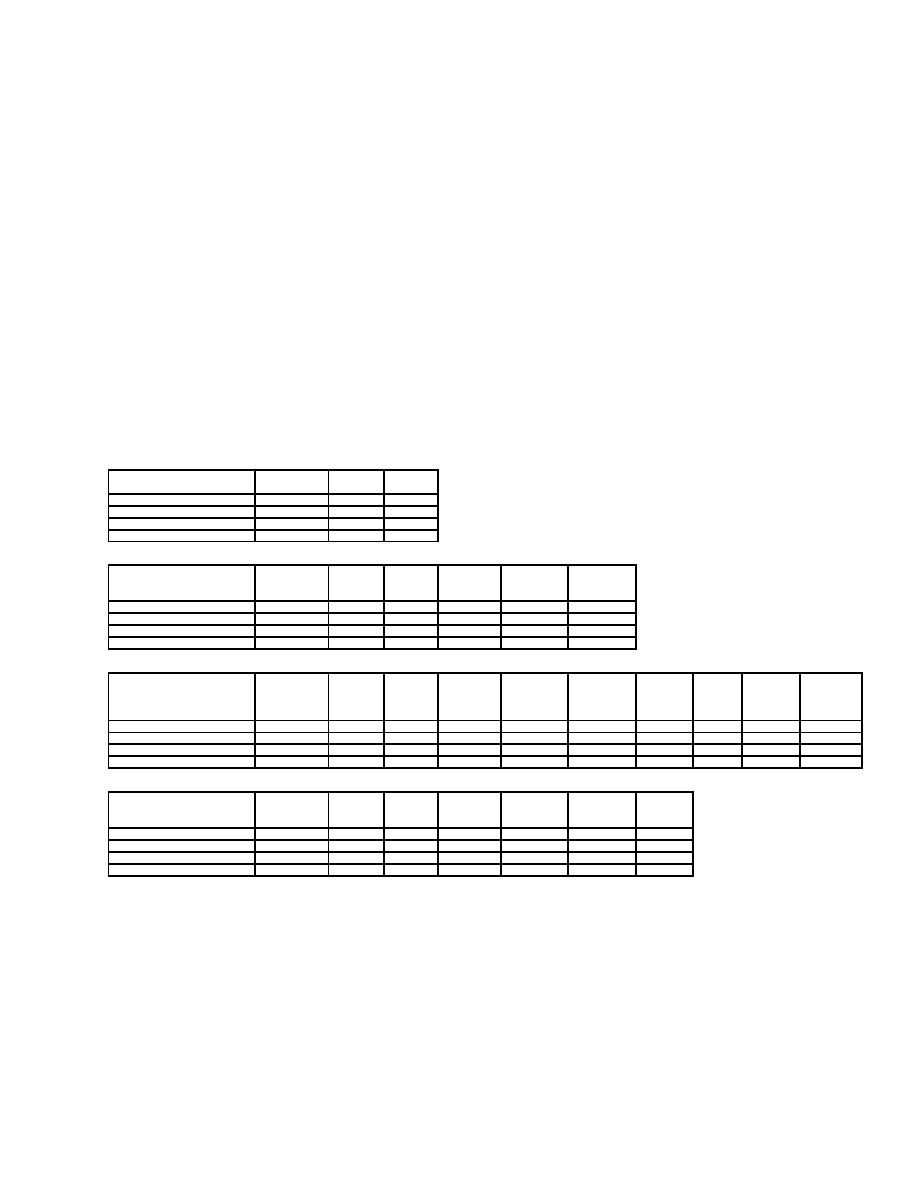

Economic Analysis of Parking Lighting Example

D-1 The following spreadsheet shows all of the values assumed for the economic

example shown on page 7-4.

Annual Operating Hours =

4380 (12 hours per day average)

Analysis Period =

10 years

Electric Energy =

||content||

.06 per kWhHPS Luminare Cost =

||content||

,500.00

HPS lamp cost =

.00

HPS ballast cost =

.00

MH Luminaire Cost =

||content||

,500.00

MH lamp cost =

.00

MH ballast cost =

.00

IND Luminaire Cost =

||content||

,500.00

Induction lamp & power supply

cost =

0.00

Equipment Cost

Luminaire

Equipment

Quantity

Cost

Total Cost

Light Type

High Pressure Sodium

16

||content||

,570

,120

Metal Halide

16

||content||

,580

,280

Induction

16

||content||

,850

,600

Energy Cost

Energy Cost

for Analysis

Luminaire

Annual

Annual

Annual

Quantity

Input Watts kWh

Energy Cost

Savings

Period

Light Type

250 watt High Pressure Sodium

16

295

20673.6

||content||

,240

,404

150 watt Metal Halide

16

185

12965

8

,779

,625

165 watt Induction

16

165

11563.2

4

,466

,938

Lamp Replacement

Lamp repl.

Labor

Cost for

Group

group

Cost

# lamps

Average

analysis

Luminaire

Lamp Life

relamp

Effective Life relampings in replaced in

(each

Lamp Cost

Annual

Light Type

Quantity

(hours)

factor

(hours)

analysis period analysis period (each)

lamp)*

Savings

period

High Pressure Sodium

16

24000

0.7

16800

2

32

.00

.00

,240

Metal Halide

16

10000

0.7

7000

6

96

.00

.00

,680

-,440

Induction

16

100000

0.7

70000

0

0

0.00

.00

||content||

,240

Summary of Total Cost for Analysis Period

Total Cost for Savings for

Average

Analysis

Luminaire

Analysis

Annual

Quantity

Equipment

Energy

Replacement Period

Period

Savings

Light Type

High Pressure Sodium

16

,120

,404

,240

,764

Metal Halide

16

,280

,779

,680

,739

-5

-

Induction

16

,600

,938

||content||

,538

,226

3

* Assumed Labor Cost: per lamp

D-1

Previous Page

Previous Page