TM

5-811-1/AFJMAN

32-1080

fill interstices in the coils and preclude the entrap-

Table 1-1. Service Conditions.

ment of air or moisture. The sealer coat may also

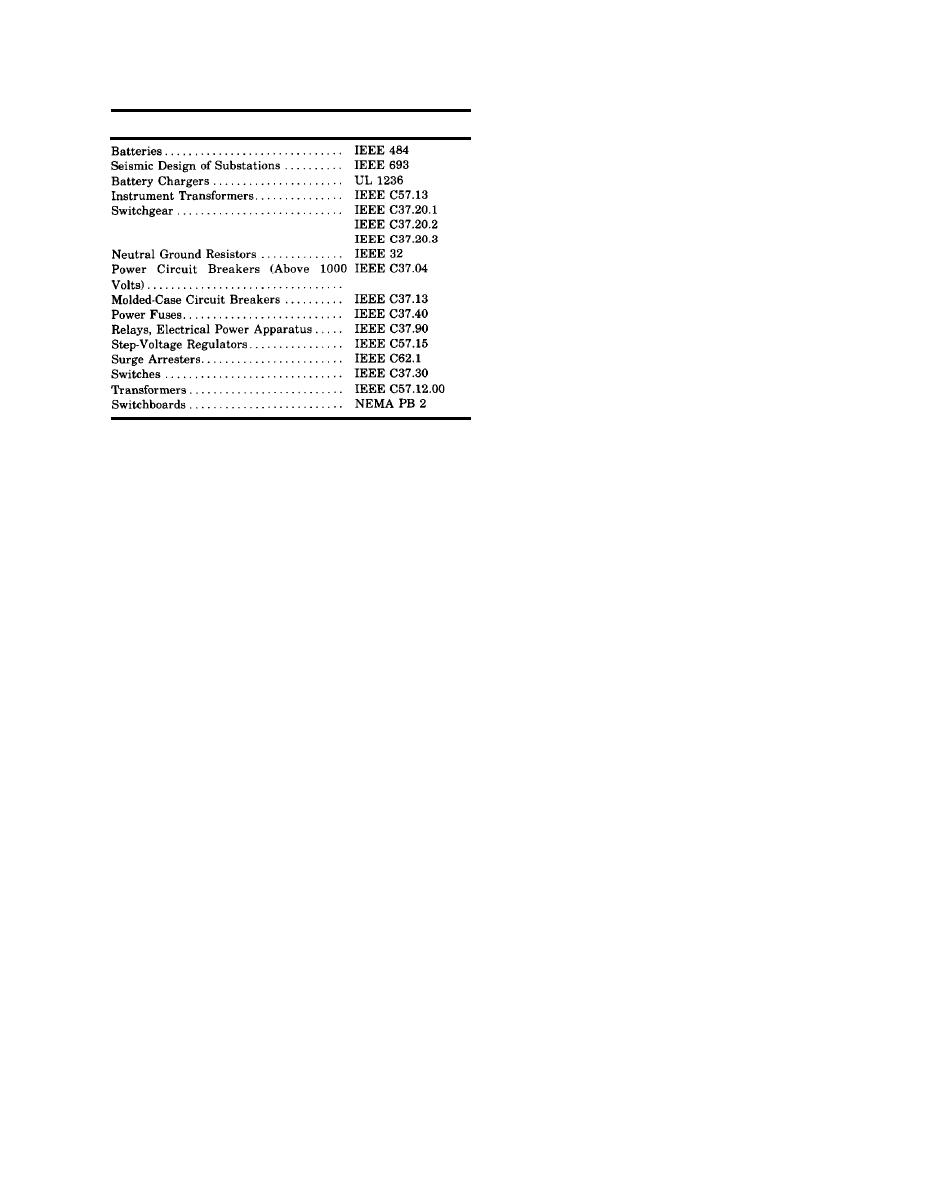

Standard

Item of Equipment

be applied by brushing or spraying.

c. Corrosive or contaminated atmospheres. Up-

grading of equipment located in atmospheres

where corrosion occurs (because of excessive humid-

ity or from industry contamination which may be

intensified by fog) will be provided only where local

practice indicates the additional cost is justified.

(1) Upgrading corrosion resistance. Where a

better than standard coating is required, a salt

spray test will be specified for the finish. Length of

the testing period will be in accordance with

standard practice for the area.

(2) Insulating devices. Where over insulation

in contaminated areas is required, bushings will be

specified for the next higher basic impulse level

(BIL) than required for that device insulation class.

d. Insect and rodent damage. The applications

b. Tropic conditions. Basic engineering practices

listed below will be investigated and implemented,

governing design and construction of electrical

as required, in areas where insert and rodent

power systems in temperate areas will be applied

damage to underground cable installations is a

to tropic zones. Potential problems which may

problem. Proven local practice will also be followed.

result from corrosion and termite infestation, as

(1) Use armored cable.

well as the feasibility of using local materials, will

(2) Use cable with higher voltage rating.

be investigated in order to select the most suitable

(3) Use cable with full concentric neutral.

elements for the system. Outdoor switchgear will

(4) Install animal guards around existing con-

be enclosed and have space heaters with automatic

crete pads and around pipe entrances on wood

controls. In typhoon areas, design will provide

walls.

sufficient strength for the extreme wind loading

(5) On new installations, install buried fiber-

conditions encountered. Where fungus control is

glass pads that animals cannot penetrate.

required, the following paragraphs will be edited

(6) Specify cable with rodent protection armor.

and included as a part of the project specifications

(7) Specify seals or cover all crevices greater

as required:

t h a n -inch.

( 1 ) Contact surfaces of devices such as

(8) Select foundation area plantings which do

switches, fuses, and circuit breakers need not be

not compliment local area pest habitats.

treated. Other materials and components which

(9) Do not use toxic chemical treatment of the

are inherently fungus-resistant or are protected by

soil.

hermetic sealing need not be treated.

e. Seismic design. The seismic design of electri-

(2) Circuit elements, not covered in above

cal installations will comply with agency criteria;

paragraph and which have a temperature rise of

TM 5-809-10; and AFM 88-3, Chapter 13. The

not more than 75 degrees F when operating at full

seismic design of electric substations will comply

load shall be treated in accordance with

with IEEE 693.

MIL-T-152. Circuit elements include, but are not

f. Electromagnetic pulse (EMP) and high-altitude

limited to, cable, wire, terminals, switchgear, pa-

electromagnetic pulse (HEMP). EMP and HEMP

nelboards, capacitors, and coils.

requirements will be in accordance with MIL STD

(3) Circuit elements, such as motor coils, dry-

188-125 and MIL HDBK 423.

type transformers, and similar electrical compo-

g. Environmental compliance. The design will

nents, which have a temperature rise exceeding 75

provide electrical systems which comply with Fed-

degrees F when operating at full load shall not be

eral, state, and local environmental regulations.

coated with a fungitoxic compound. Instead, such

Transformer dielectric information in chapter 8

components shall be given two coats of varnish

will be applied to all dielectric-filled equipment.

and one sealer coat, both conforming to Type M,

1-11. Explanation of Abbreviations and Terms.

Class 130 of MIL-I-24092. Coats shall be applied

by the vacuum-pressure, immersion, centrifugal,

Abbreviations and terms used in this manual are

pulsating-pressure, or the built-in method so as to

explained in the glossary.

1-6

Previous Page

Previous Page