TM 5-811-7

suspended in the center of the riser pipe and are spliced to a No.4 AWG cable. The top anode is placed 1 foot

from the tank base. The remaining four anodes are spaced at 4-foot intervals.

(b) Each button anode has its own No.8 AWG 7-strand copper cable (HMWPE) run in conduit to

a resistor box mounted at eye level on a tank leg. The riser anode's one No.4 AWG 7-strand cable is run in

conduit to the resistor box. If required to get proper current output, a resistor must be installed in the riser

anode circuit at the time of rectifier sizing. The rectifier must be sized after the anodes are installed and must

be mounted at eye level adjacent to the resistor box.

D-6.

Elevated steel water tank.

This impressed current design is for a tank that has not been built; thus, it is not possible to measure current

requirements and other factors. Calculated estimates are used.

a. Design data.

(1) Tank capacity will be 500,000 gallons.

(2) Tank height (from ground to bottom of bowl) will be 115 feet.

(3) Tank diameter will be 56 feet.

(4) The tank's high water level will be 35 feet.

(5) Overall tank depth will be 39 feet.

(6) Vertical shell height will be 11 feet.

(7) Riser pipe diameter will be 5 feet.

(8) Tank will be ellipsoidal on both top and bottom.

(9) All inner surfaces will be uncoated.

(10) Design for a maximum current density of 2 milliamperes per square foot.

(11) Electric power available will be 120/240-volt a.c., single phase.

(12) String-type HSCBCI anodes will be used.

(13) Design for a 10-year life.

(14) Water resistivity is 4000 ohm-centimeters.

(15) The tank water must not be subjected to freezing.

(16) An assumed deterioration rate is 1.0 pound per ampere-year.

(17) Anode efficiency (assumed) is 50 percent.

b. Computations.

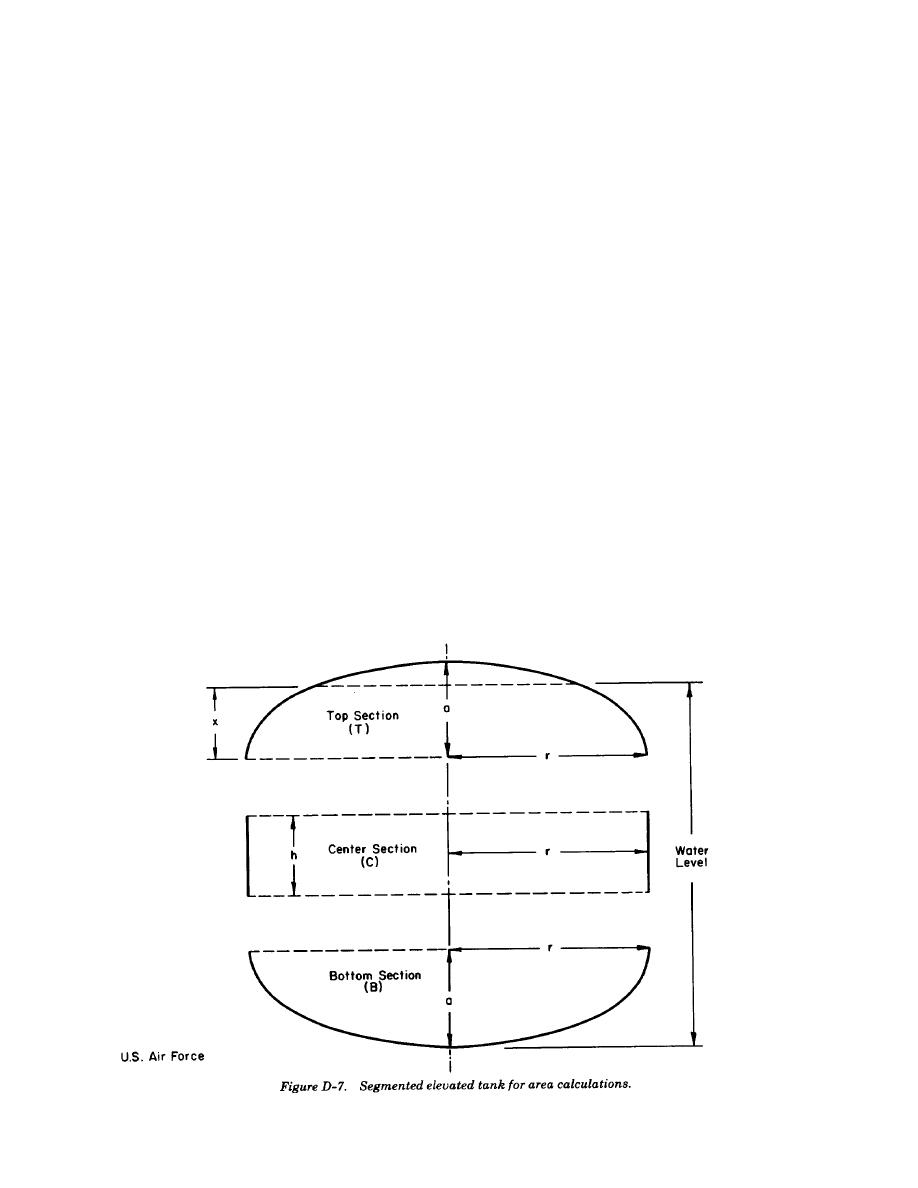

(1) Find the area of wetted surface or tank bowl (figure D-7).

D-13

Previous Page

Previous Page