MIL-HDBK-1004/10

Table 21

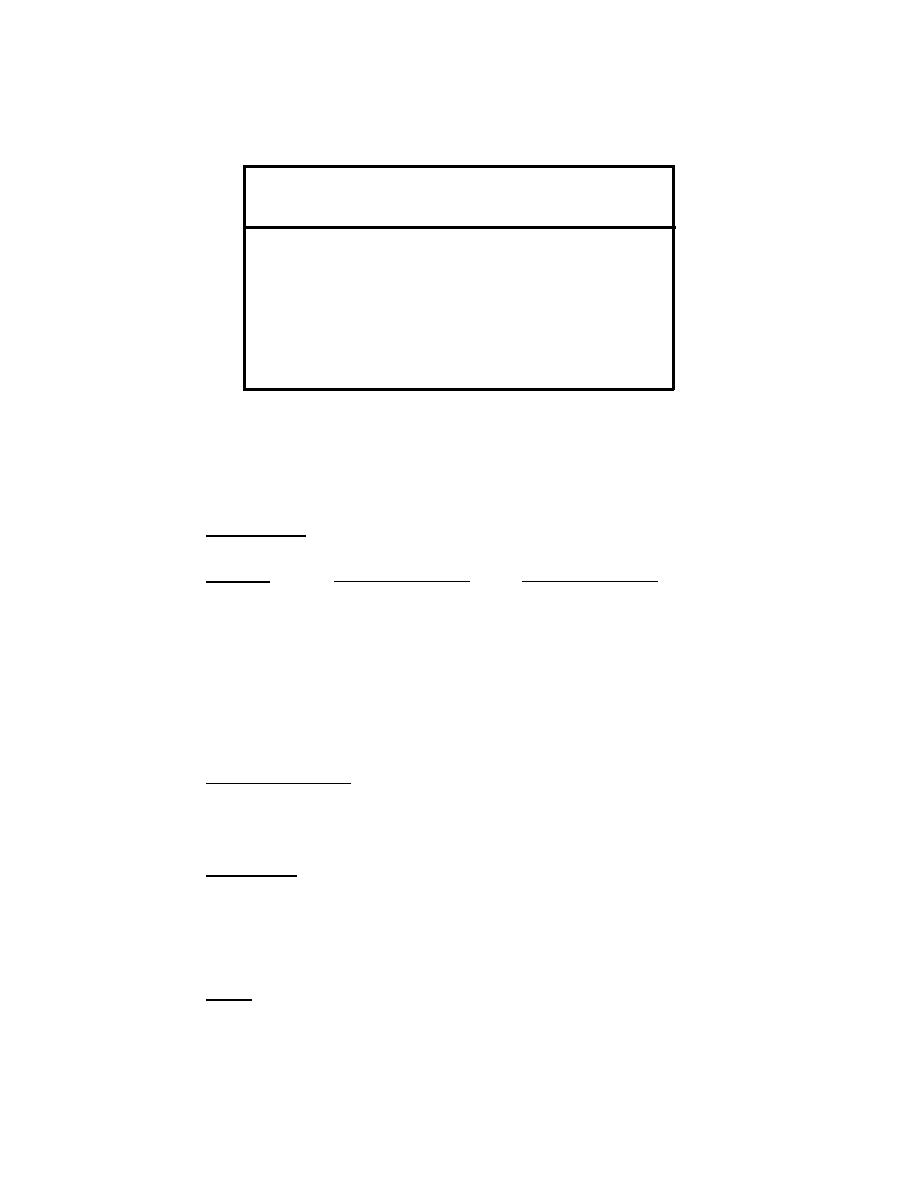

Zinc Anodes - Special Sizes for Use

in Seawater

WEIGHT

SIZE (in.)

LENGTH (in.)

(lb/in.)

0.5

1.4

x

1.4

6

to

60

1

2

x

2

6

to

60

2.3

3

x

3

6

to

60

4.2

4

x

4

6

to

60

6.5

5

x

5

6

to

48

12.8

7

x

7

6

to

36

21.0

9

x

9

9

to

24

23.4

9

x

10

9

to

24

26.0

10

x

10

9

to

24

NOTE:

A variety of cores are available with the

different sizes.

Composition. The compositions of the standard zinc alloy and the

7.8.2.1

alloy formulated for use in seawater are given below:

Standard Alloy1

Seawater Alloy2

Element

Aluminum

0.005% max

0.10 - 0.50%

Cadmium

0.003% max

0.025 - 0.15%

Iron

0.00014% max

0.005% max

Lead

0.003% max

0.006% max

Copper

-

0.005% max

Silicon

-

0.125% max

Zinc

Remainder

Remainder

1

Specification ASTM B-148, Type II

2

Specification ASTM B-148, Type I; or MIL-A-18001H

7.8.2.2

Anode Efficiency. The theoretical anode consumption for zinc is

23.5 lbs/A

yr or 372 ampere hours per pound (A hr/lb). The efficiency of zinc

is greater

than that of magnesium. The efficiency of zinc is commonly 90

percent to

95 percent regardless of current output. For design purposes, 90

percent is

used for the efficiency of zinc.

Potentials. The open circuit potential of both commonly used zinc

7.8.2.3

anode materials is -1.10 V in most soils or natural waters. The relative

potential between zinc and iron is dependent upon temperature. At

temperatures above ambient, the potential difference between the two materials

is reduced. In some fresh waters, the potential can reverse at temperatures

above 140 degrees F. Zinc should not be used to protect steel in such cases

as hot water heaters.

Sizes. Both standard alloy and seawater type zinc anodes are

7.8.2.4

available in a wide variety of sizes and shapes. Anodes used in soil usually

have a galvanized mild steel rod core. This core is attached to the anode

cable during installation of the anode. In both fresh water and seawater

applications the anode is often attached directly to the structure to be

protected by welding or bolting the steel rod, pipe, or strap core to the

125

Previous Page

Previous Page