UFC 3-570-06

JANUARY 31 2003

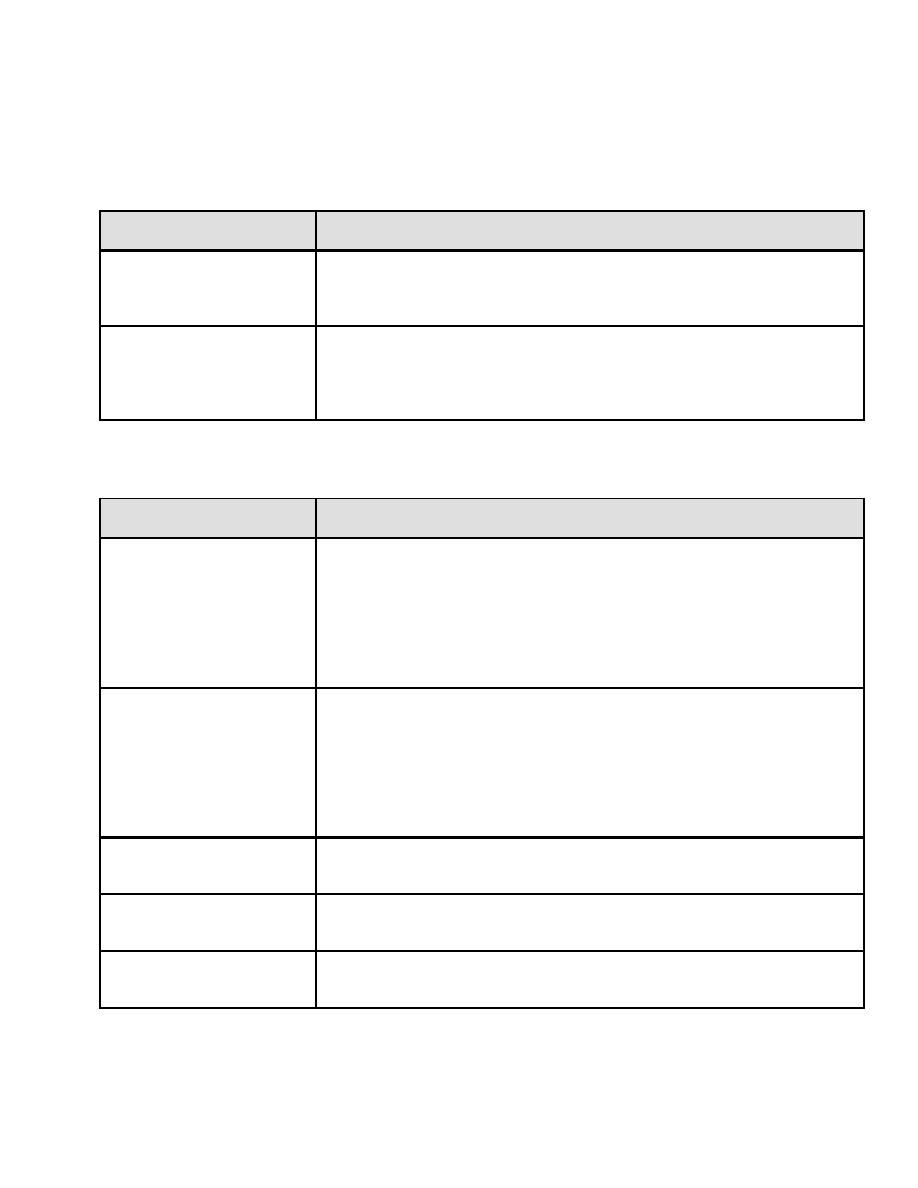

Table 4-5. Water Tank Calibration CP System Component Tests

CP SYSTEM TYPE

TEST MEASUREMENT

GALVANIC SYSTEMS

Measure anode-to-structure current using (in order of preference) a clamp-on

milliammeter, a multimeter measuring millivolts across a calibrated shunt, or a

multimeter connected in series measuring milliamperes.

IMPRESSED CURRENT

a)

Perform the rectifier operational checkout (paragraph 4-5).

SYSTEMS

b)

Calculate the rectifier efficiency by dividing the calculated

output DC power by the factored input AC power.

Table 4-6. Water Tank Calibration Potential Measurements

STRUCTURE TYPE

POTENTIAL MEASUREMENT LOCATIONS

TANK WALLS

Position the reference cell near the water surface, at mid-depth and at

the bottom in the following locations:

a)

Next to the tank wall directly adjacent to each anode string.

b)

Next to the tank wall midway between two adjacent anode

strings.

TANK BOTTOM

Locate the reference cell:

a)

Two inches above the tank bottom directly beneath each

anode string.

b)

Two inches above the tank bottom and as far away from the

anode strings as possible.

METALLIC RISER

Locate the reference electrode adjacent to the riser wall at intervals of

(Elevated Water Tanks)

1.5 meters (5 feet) from the top to the bottom of the riser.

PERMANENT

Measure and compare the potential of each permanent cell to a portable

REFERENCE CELLS

reference cell to determine its accuracy.

ALL TANKS

Annotate the water level for comparison to past and future

measurements.

4-4.2.2

For all tanks, compare potential measurements to measurements previously

4-9

Previous Page

Previous Page