UFC 4-150-07

19 June 2001

Latex modified concrete, compared to epoxy concrete, is vapor

permeable and lower in cost. Even though permeable to vapor, it is not very

permeable to liquids. Repairs requiring thin sections, which will be exposed to the

sun, should be breathable so that vapor pressure does not build up behind the

patches or overlays. Vapor pressure can debond and cause a patch to spall off.

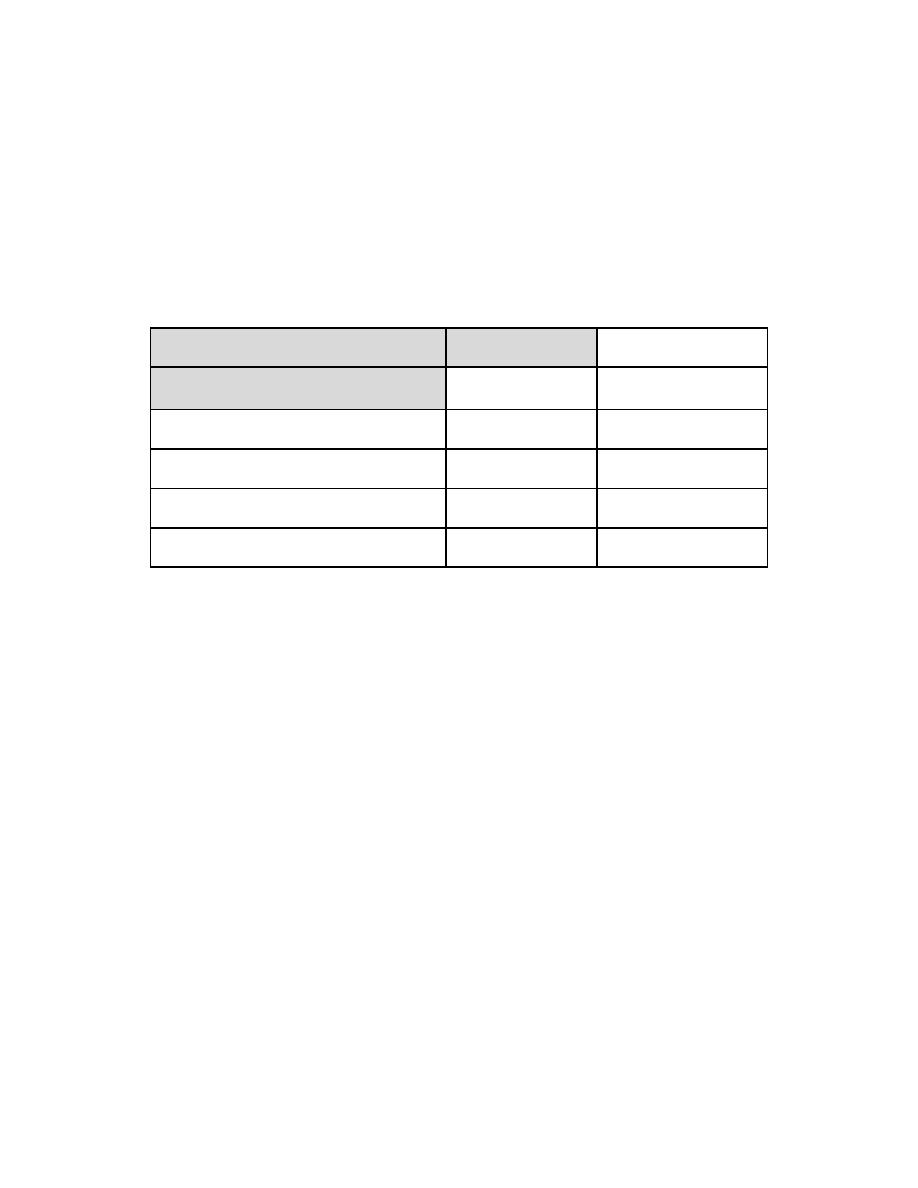

Recommended mix proportions for thin and medium thickness repairs

are in Table 7-1.

Table 7-1 Recommended Mix Proportions

Finished Thickness

13 mm to 32 mm

32 mm and up

(1/2 to 1 inch)

(1 inch and up)

Latex to cement ratio

0.10 to 0.20

0.10 to 0.20

Water to cement ratio

0.30 to 0.40

0.30 to 0.40

Fine aggregate to 1 part cement

3.0 to 3.5 parts

2.5 to 3.1 parts

Coarse aggregate to 1 part cement

2.5 to 3.1 parts

1.4 to 2.0 parts

Prepackaged latex modified mortars, or just the liquid latex modifiers,

are commercially available. The mortar mixes can be converted to concrete by

adding coarse aggregate. Latex modified concretes are sensitive to improper

placement techniques, and noted failures have occurred. Carefully follow the

manufacturers' recommendations.

7-1.2.3

Epoxy Concrete. Epoxy concrete does not contain Portland cement.

It is a mixture of an epoxy resin and aggregate. Epoxy concrete is the most

popular polymer concrete used because of its many physical properties that can

be obtained, good adhesion to existing concrete, and availability. Other

commercially available polymers are acrylics, polyesters, polyurethanes, and

polyvinyl acetate.

Epoxy resin, when mixed with a curing agent, forms a thermosetting

plastic that rapidly develops adhesive strength. Epoxy mixes are used for several

purposes:

To repair cracks by injecting the resin.

To make epoxy mortar or concrete by mixing the resin with fine

and coarse aggregate.

7-5

Previous Page

Previous Page