TM 5-840-2

classification yard, and the tracks serving the

bituminous concrete, portland cement concrete,

shelter will lead from the classification yard.

precast concrete planks, wood planks,

prefabricated rubber planks, modular plastic

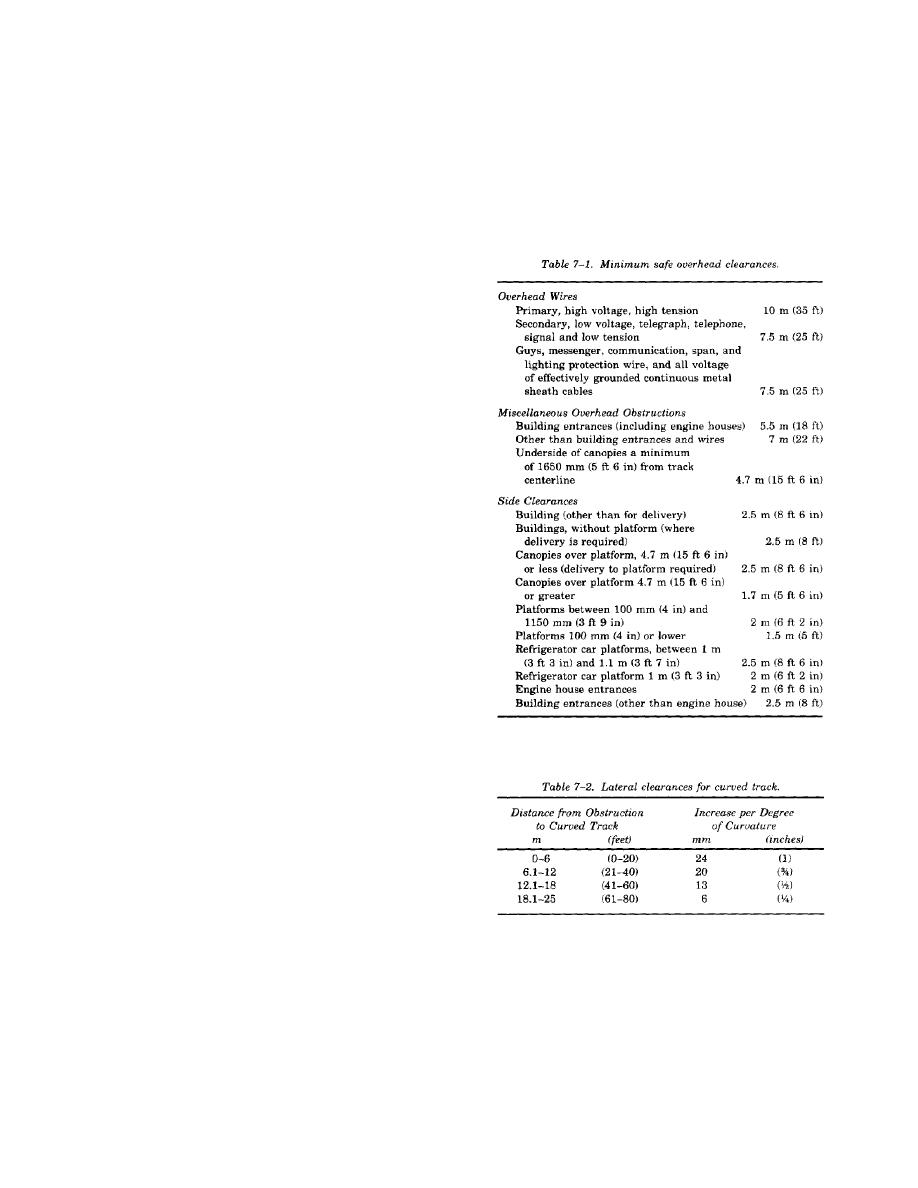

7-3. Dimensions and clearances.

crossings, used rail, two-component epoxy and

rubber. Details of these methods and their

Dimensions of rail facilities for storage depots

advantages can be found in TM 5-627/MO-

within CONUS will be based on the standard

103/AFM 91-33.

American track gage of 1.43 m (4 ft 8 in).

Overhead clearances and platform heights are

measured from top of rail, and side clearances are

measured from centerline of track. Any item that

protrudes within the limits of these clearances is

dangerous, and protection must be provided by

appropriate warning signs or devices. For example,

telltales must be used for overhead clearances

ranging between 5.5 and 7 m (18 and 22 ft). The

standard clearances are listed in table 7-1; local

clearances or special conditions may require greater

clearances. On curves, side clearances listed in table

7-1 will be increased 25 mm (1 in) per degree of

curvature, with a maximum increase of 450 mm (18

in). When the fixed obstruction is on tangent track

but the track is curved within 25 m (80 ft) of the

obstruction, the lateral clearances shall be increased

according to table 7-2. In a storage depot, train

speeds should not be high enough to warrant

superelevation of the track; however, if it is

deemed necessary to superelevate any trackage,

horizontal clearance on the inside rail shall be

increased 3 times the amount of superelevation of

the outside rail in addition to the 25 mm (1 in) per

degree of curvature.

7-4. Crossing.

Crossing surfaces must be as smooth as possible,

and the materials selected for this purpose must be

suitable for the type of traffic using the crossing.

Although it may be desirable to match the material

and texture of approach pavements, consideration

must be given to a material and an installation that

is economical to maintain and which will have a

long service life. Materials such as portland cement

concrete or bituminous concrete are economical to

install, but are costly to remove and replace. Wood

plank and prefabricated materials may be a little

more costly to install, but are removable and

reusable and therefore are more economical to use

in the long run. Furthermore, they are easily

removed and replaced, they facilitate the inspection

of the track. Materials suitable for crossings are:

7-3

Previous Page

Previous Page