MIL-HDBK-1191

CONVENTIONAL FOOD SERVICE

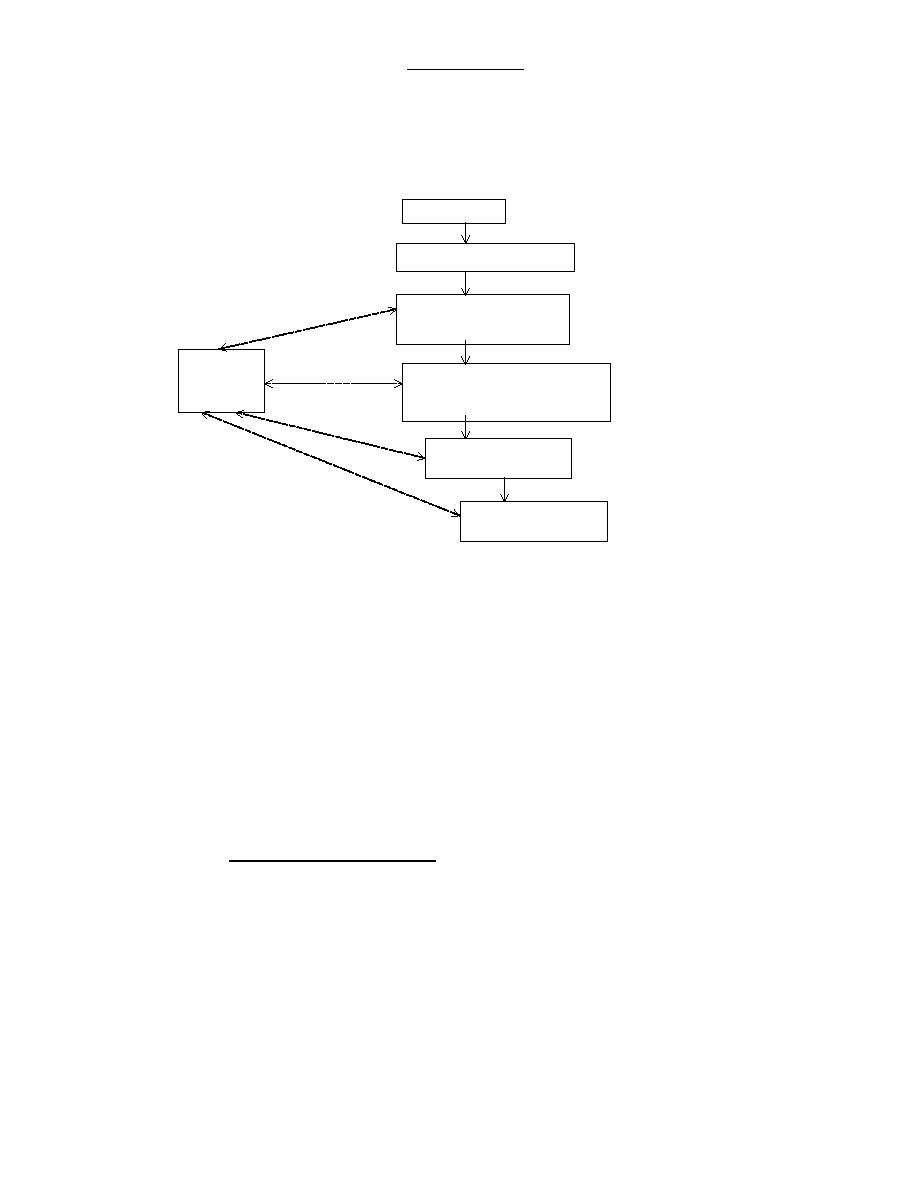

FLOW DIAGRAM

RECEIVING

STORAGE

Freezer, Refrigerator, Room Temperature

PREPROCESSING

Vegetable Processing

Meat Processing

Ingredient Procesing

SANITATION

PREPARATION & ASSEMBLY

CENTER

Cooking Center

Warewashing

Baking Center

Pot Washing

Nourishment Center

Final Assembly & Preportioning Center

SERVICE

Cafeteria Serving Line

Tray Assembly

CUSTOMER

Patients

Staff, Military Personnel, Guests

Figure 22-1: Conventional Food Service Flow Diagram

Conventional Food Systems are equipped with full service bakery, salad and

sandwich preparation areas. Current studies show that temperature

controlled cold rooms (50 F) are ideal for preparing cold salads, sandwiches

and breaking down meat into meal quantities. Hazard Analysis and Critical

Control Point (HACCP) studies show that food borne illness is decreased due

to the increase of food safety created by the refrigerated food preparation

environment. Butcher shops complete with meat saw and grinder, are not

needed in most facilities. The salad/sandwich preparation area should be

designed so that finished food products can be moved easily into a walk-in

refrigerator that safely stores the items at or below 40 F. Coordinate

table top equipment items with specific facility requirements.

22.6

CONVENIENCE FOOD SYSTEM. With a convenience system almost all

foods utilized are fully prepared foods purchased from outside sources and

properly stored. Some in-house cooking and/or preparation will supplement

purchased prepared foods (salads, vegetables, etc.). The prepared foods are

subsequently brought to their appropriate serving temperatures on the

premises as near to meal times as possible and maintained at these

temperatures until served. Today many food services are using different

forms of convenience foods that require extensive rethermalization equipment

units that also double as a holding unit, thereby increasing the flexibility

of the equipment item. Refrigeration and freezer space is also an important

consideration. Space for these units should be calculated at 0.014 cubic

meter per meal served per day. This figure also depends on prime vendor

delivery and should be significantly increased if deliveries are not

scheduled at least three times per week. Material handling equipment and

22-3

Previous Page

Previous Page