CEMP-E

TI 850-02

AFMAN 32-1125(I)

1 MARCH 2000

c. Recommended New Rail Sections.

(1) Weights and sections recommended for new rail purchases are: 115RE, 132RE, 133RE, and

136RE, with 115RE being the preferred. These are the standard sections recommended by the AREMA

and should be available for many years.

(2) Rail may be purchased in either 39- or 80-ft lengths. Rail 80 ft long has the advantage of

reducing the number of joints to half that for 39 ft rail. For small purchases where the rail may be

transported by truck, 39 ft lengths may be more cost effective.

d. Relay (Secondhand) Rail.

(1) Secondhand rail that meets the specifications in table 6-10 either as is or after cropping off the

ends, may be used for rehabilitation or new construction. Before selecting relay rail, the cost, condition,

and availability of matching joint bars and tie plates must be investigated.

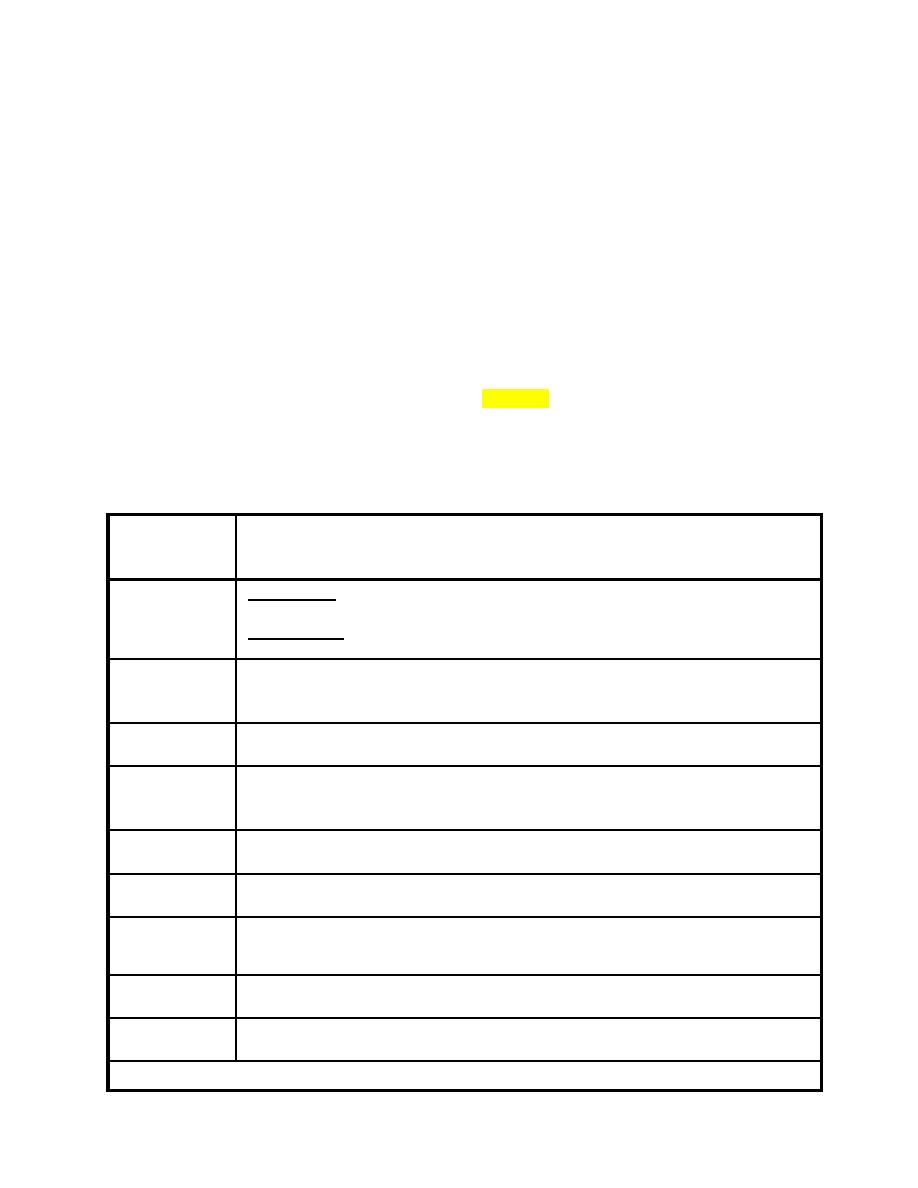

Table 6-10. Dimension and Surface Specifications for Relay (Secondhand) Rail

Length

For Standard 39 ft lengths:

Not more than 10% of lot between 33 ft and 39 ft.

No rail shorter than 33 ft.

Vertical

90 lb or Larger: Average top wear 5/16 in. or less with maximum at any one location of 11/32

in.

Wear

Less Than 90 lb: Average top wear 1/4 in. or less with maximum at anyone location of 9/32

in.

Side

At least one side must meet the following:

Wear

90 lb or Larger - Maximum of 5/16 in

Less Than 90 lb - Maximum of 1/4 in.

Lip or

Maximum of 1/16 in., either as is or obtained by grinding off excess.

Overflow

Engine

Maximum of 1/2 in. diameter (or 1/4 in. wide by 1/2 in. long) and 1/32 in. deep.

Burns

Maximum of four engine burns per rail.

Engine burns on no more than 8% of the lot.

End Batter

Maximum of 1/8 in. when measured 1/2 in. from the rail end with an 18 in. straightedge.

And Chipping

Running Surface

Maximum size of 1/4 in. wide by 1/2 in. long and 1/32 in. deep.

Damage

Maximum of four damaged spots in any one rail.

Defects Not

Bolt hole cracks or breaks, broken base, crushed head, detail or engine burn fractures, head-

web or web-base separations, piping, horizontal or vertical split head or web, torch cuts or

Permitted

flame gouges, compound or transverse fissures, deep pitting from corrosion.

Condition and

Rail must be: free from obvious defects; clean in appearance; straight in line and surface and

without kinks; and free from base defects such as plate wear and spike notches.

Appearance

Internal

Rail to be ultrasonically inspected before or after installation.

Inspection

Defective sections to be rejected and replaced.

Note: See AREMA Manual chapter 4, part 3 for rail defect definitions and illustrations.

6-33

Previous Page

Previous Page