CEMP-E

TI 850-02

AFMAN 32-1125(I)

1 MARCH 2000

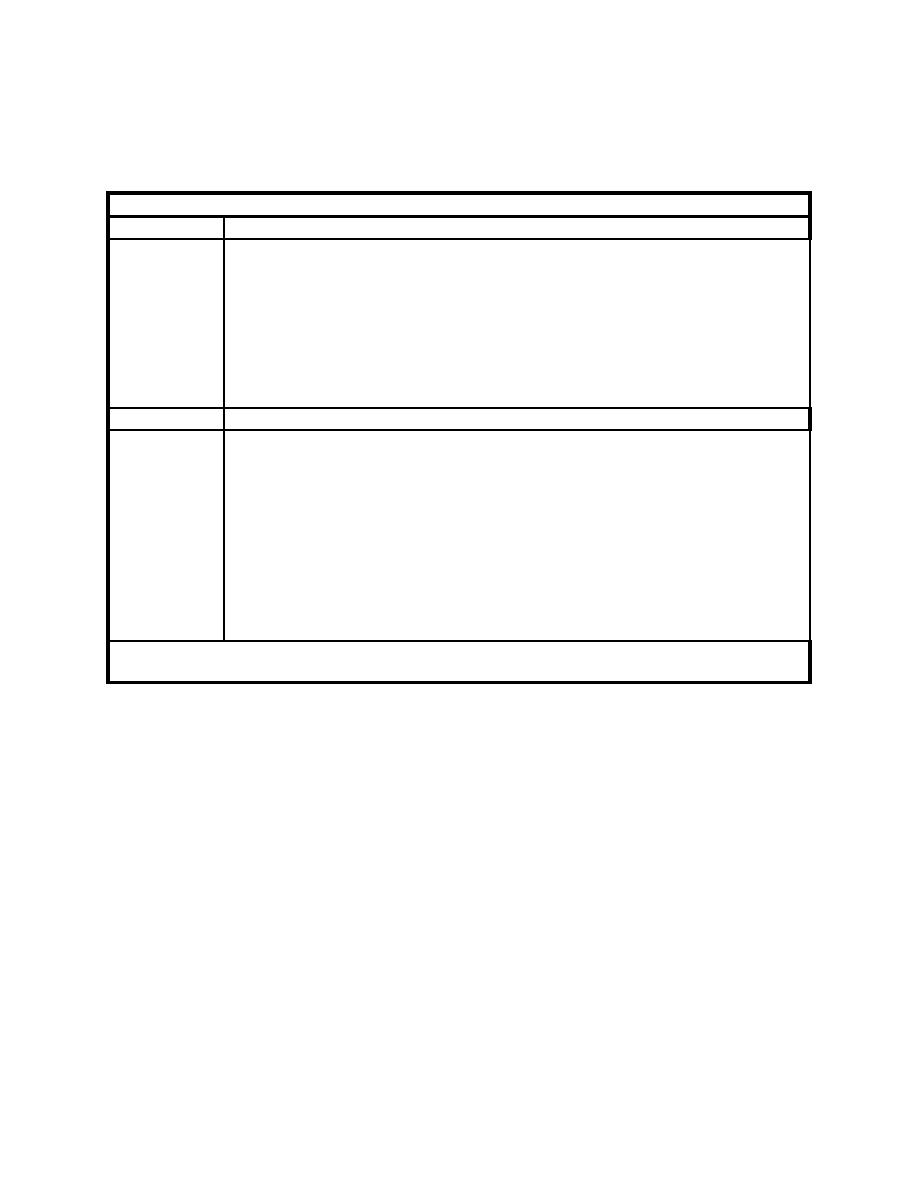

Key to Table 7-1:

Traffic Category

Description (See Note Below)

I

Up to 1% traffic 2-axle trucks.

II

1-10% 2-axle trucks.

III

Up to 15% traffic 2-axle trucks, up to 1% trucks with 3 or more axles.

IV

Up to 25% traffic 2-axle trucks, up to 10% trucks with 3 or more axles.

IV-A

More than 25% truck traffic, all types.

V

Tracked vehicles up to 60,000 lb gross weight.

VI

Tracked vehicles up to 90,000 lb gross weight.

VII

Tracked vehicles up to 120,000 lb gross weight.

Crossing Type

Description

1

Gravel Crossing with Timber Flangeway Header.

2

Timber Crossing.

3A

Asphalt Crossing.

3B

Asphalt Crossing with Timber Flangeway Header.

3C

4-Rail Asphalt Crossing.

3D

6-Rail Asphalt Crossing.

4A

Cast-in-Place Concrete Crossing.

4B

Prefabricated Concrete Panel Crossing.

4C

Sectional Monolithic Concrete (No Ties).

5

Full Depth Rubber Crossing.

NOTE: More detailed description of Road/Street Classes and Traffic Categories can be found in TM 5-822-2/AFM

88-7, Chap. 5, including provision for forklifts.

(3) Constructed Surfaces. Crossing types 1, 3A through D, and 4A may be categorized as

constructed crossings. With this type, the road or street is basically extended across the track to form a

crossing. Separate flangeway headers may be used, but the crossing is generally made from available

road and track materials and fabricated on-site. This arrangement provides site-specific versatility to fit a

crossing in-place at the time of construction. These crossings are readily adaptable to any track

curvature, super-elevation, or gradient. Generally, these crossings cannot be readily removed and

replaced when track or road maintenance is required.

(4) Prefabricated Surfaces.

(a) Crossing Types 2, 4B, 4C, and 5 may be categorized as prefabricated. These crossings are

generally ordered from a manufacturer and are assembled at the site from surface panels using special

panel attachment or track fastening hardware. Prefabricated crossings often require longer ties than

standard and must be ordered specifically for the size of rail and tie plates, and anchors (if used) at the

crossing; this ensures panel height will match rail height and that sufficient clear space is available under

the panels for the tie plates and rail fastenings. Prefabricated crossings must also be ordered to match

any track curvature and for crossing angles that vary significantly from 90 degrees. It is suggested that

prefabricated crossings be ordered to extend at least 2 ft on each side beyond the widest part of the road

through the crossing, allowing for crossing angle as needed.

7-3

Previous Page

Previous Page