*TM 5-810-4/AFM 88-8, Chap. 3

CHAPTER 2

AIR INTAKE

2-1. Location.

locating the air intake at the coolest air source, usually the

The intake for a compressor will be located either outdoors

north side of the building.

or indoors, whichever provides better air quality. Elevation

of the compressor relative to sea level is required to deter-

2-3. Intake pipe materials.

mine atmospheric pressure and density of intake air. Air

The inside of intake piping must be smooth and not subject

quality will be judged by its temperature, humidity, and

to rusting or oxidation. Rust that flakes off will enter and

cleanliness. Indoor sound levels are lower when the air

damage the compressor. Acceptable intake air piping mater-

intake is located outside the building, especially with a re-

ials include plastic, copper, stainless steel, aluminum, or

ciprocating compressor. Where practicable, an outside air

galvanized steel. On metallic piping, mechanical couplings

intake should be located on the coolest side of the building.

will be used. Welded joints must be avoided since weld

at least 6 feet above the ground or roof. For reciprocating

beads can break free, enter, and damage the compressor.

units, the intake will be located at least 3 feet away from any

wall to minimize the pulsating effect on the structure, and an

2-4. Critical pipe lengths.

intake filter silencer or an intake pulsation damper should be

Resonance of intake piping with reciprocating air compres-

provided. A compressor intake must not be located in an

sors is prevented by avoiding certain pipe lengths. These are

enclosed courtyard. Intake pipes must be positioned to

called "critical pipe lengths," and are a function of the air

prevent entrance of snow or rain water, and must be far

temperature and the speed of the compressor in revolutions

enough from steam, gas, or oil engine exhaust pipes to insure

per minute (rpm). Critical pipe lengths must be verified with

intake air that is free of moisture or pollution. Protection by

equipment manufacturers.

a hood or louvers should be considered when the intake is

subject to adverse weather conditions. It is desired that the

2-5. Intake air filter.

intake air filter be located on the compressor and piped from

The selection of the filter type is based on whether the air

the enclosed filter hood to the outside. This method prevents

compressor to be used is lubricated or nonlubricated, and on

ingestion of foreign material to the internals of the

the quality of ambient air.

compressor should the piping have a poor joint or other leak

a. Viscous impingement filters have an efficiency of 85

upstream of the intake filter.

to 90 percent of particle sizes larger than 10 microns. This

type of filter is acceptable for lubricated reciprocating com-

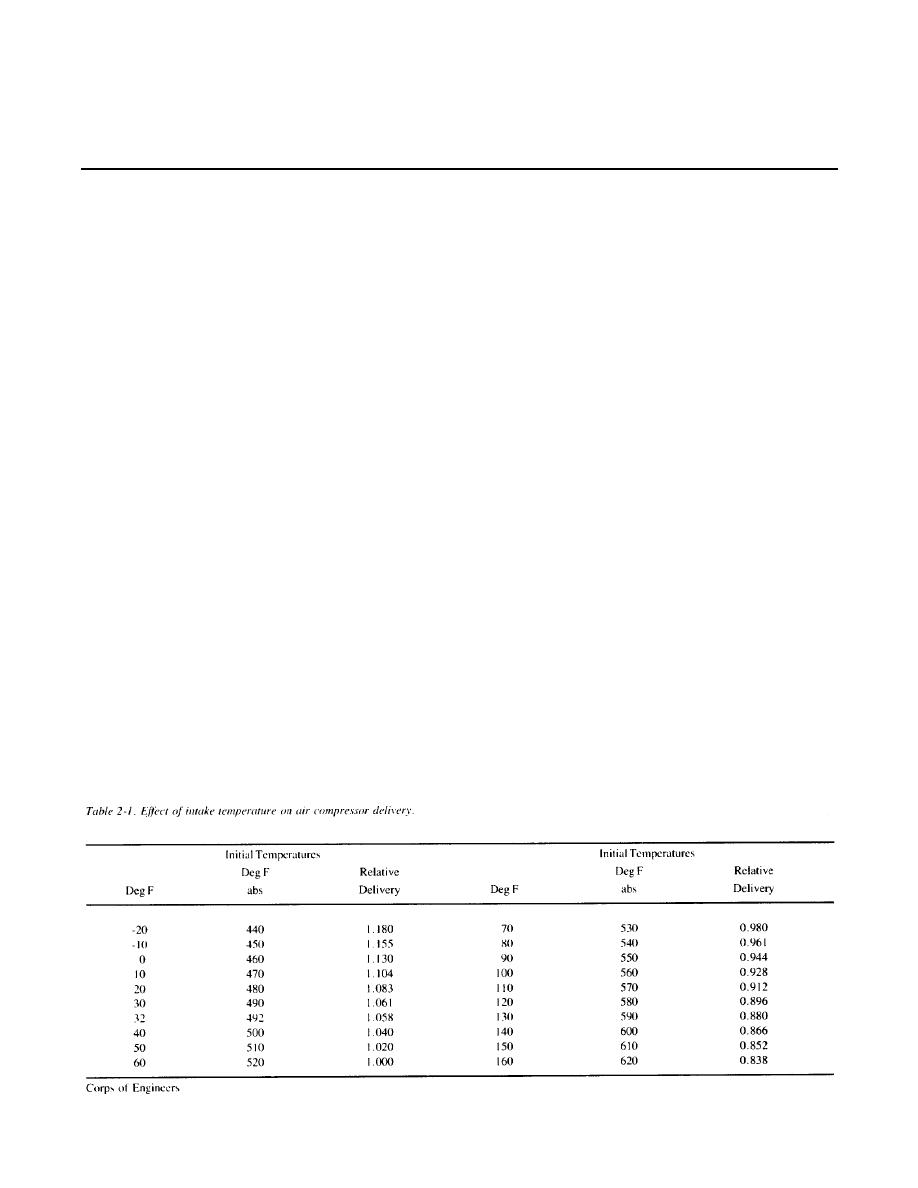

2-2. Intake temperature.

pressors operating under normal conditions.

The density of air varies inversely with its temperature; an

b. Oil bath filters have an efficiency of 96 to 98 percent

increase in delivery of approximately I percent is gained for

of particles sized larger than 10 microns. This type of filter

every 5 degrees F reduction of intake temperature. Table 2-I

is more expensive, and for the most part no longer recom-

shows the effect of inlet or initial temperature on air

mended by compressor manufacturers, but may be considered

compressor delivery and demonstrates the importance of

for lubricated reciprocating compressors operating

2-1

Previous Page

Previous Page