*TM 5-810-4/AFM 88-8, Chap. 3

CHAPTER 5

AFTERCOOLER AND SEPARATOR

5-1.

Design.

t-rise = degrees F, water temperature rise.

To keep condensation from forming in the cylinder inlet

An after cooler complete with moisture separator to condense

ports, keep the temperature of cooling water entering cylin-

and remove water vapor and oil vapor will be used. After-

der jackets 15 degrees F, above the dew point of the

coolers should be air-cooled type or water cooled type to best

incoming air. This can be accomplished by circulating water

suit installation and economic requirements. Air is cooled to

through the intercooler first, and then piping the same water

below its dew point in the after cooler, and the condensed

through the cylinder jackets. An alternate method is to reduce

water and oil are then removed by the moisture separator and

the water supply to the cylinder jackets. The compressor

automatic moisture trap. The after cooler and separator will

manufacturer should be consulted to verify the cooling water

be located between the compressor and air dryer or receiver,

requirements for cooling compressor cylinder jackets.

as close to the compressor as possible. Water cooled

aftercoolers should be protected against freezing. As a

general rule, a differential of 15 degrees F should be

maintained between the temperature of the cooling water

entering and the air temperature leaving the aftercooler.

5-2.

Circulating water.

An adequate waterflow through the intercooler, cylinder

jacket, and aftercooler is required for cooling the compressor,

cooling the compressed air, and for moisture removal. A

waterflow sensing control (flow switch) is needed wich

verifies that sufficient cooling water is flowing before the

compressor is allowed to start. Water for the aftercooler for

liquid seal rotary compressors should be piped in series with

the compressor. Waterflow, prior to startup, for rotary screw

compressors and rotary lobe compressors is not required.

Piping will be designed to conform to the manufacturer*s

recommendations. A strainer or filter should be used in the

piping system to reduce fouling of the cooler system com-

ponents.

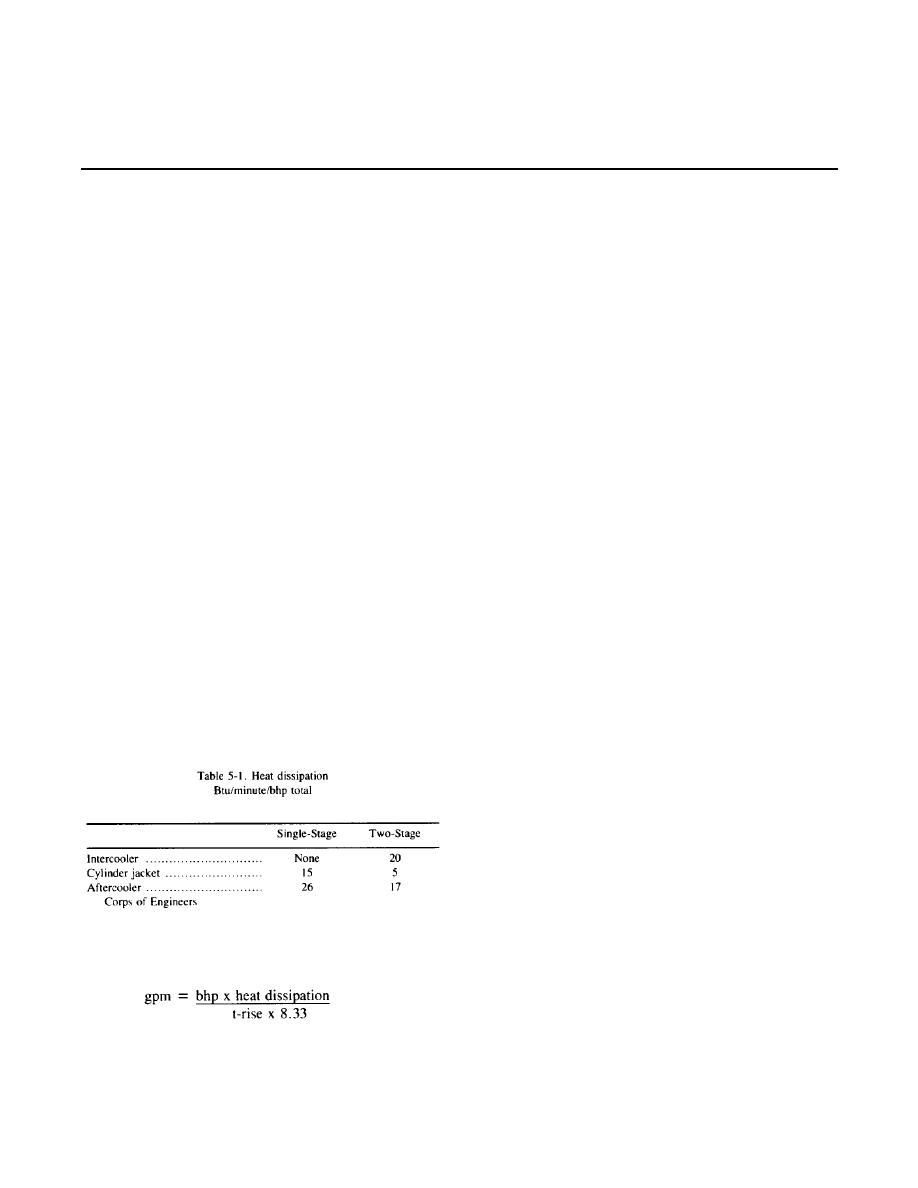

a. Heat dissipation from intercoolers, cylinder jackets,

and aftercoolers is listed in table 5-1.

b. The amount of cooling water required for intercoolers,

cylinder jackets, and aftercoolers may be determined as

follows:

Where:

gpm = gallons of water flow per minute.

bhp = air compressor brake horsepower.

Heat dissipation = value from table 5-1.

5-1

Previous Page

Previous Page