*TM 5-810-4/AFM 88-8, Chap. 3

CHAPTER 7

AIR RECEIVER

7-1.

Functions.

The air receiver dampens pulsations entering the discharge

line from the compressor; serves as a reservoir for sudden or

unusually heavy demands in excess of compressor capacity;

prevents too frequent loading and unloading (short cycling)

of the compressor; and separates moisture and oil vapor,

allowing the moisture carried over from the aftercoolers to

precipitate. Air receivers shall be constructed in accordance

with ASME Boiler and Pressure Vessel Code Section VIII.

7-2.

Determining receiver size.

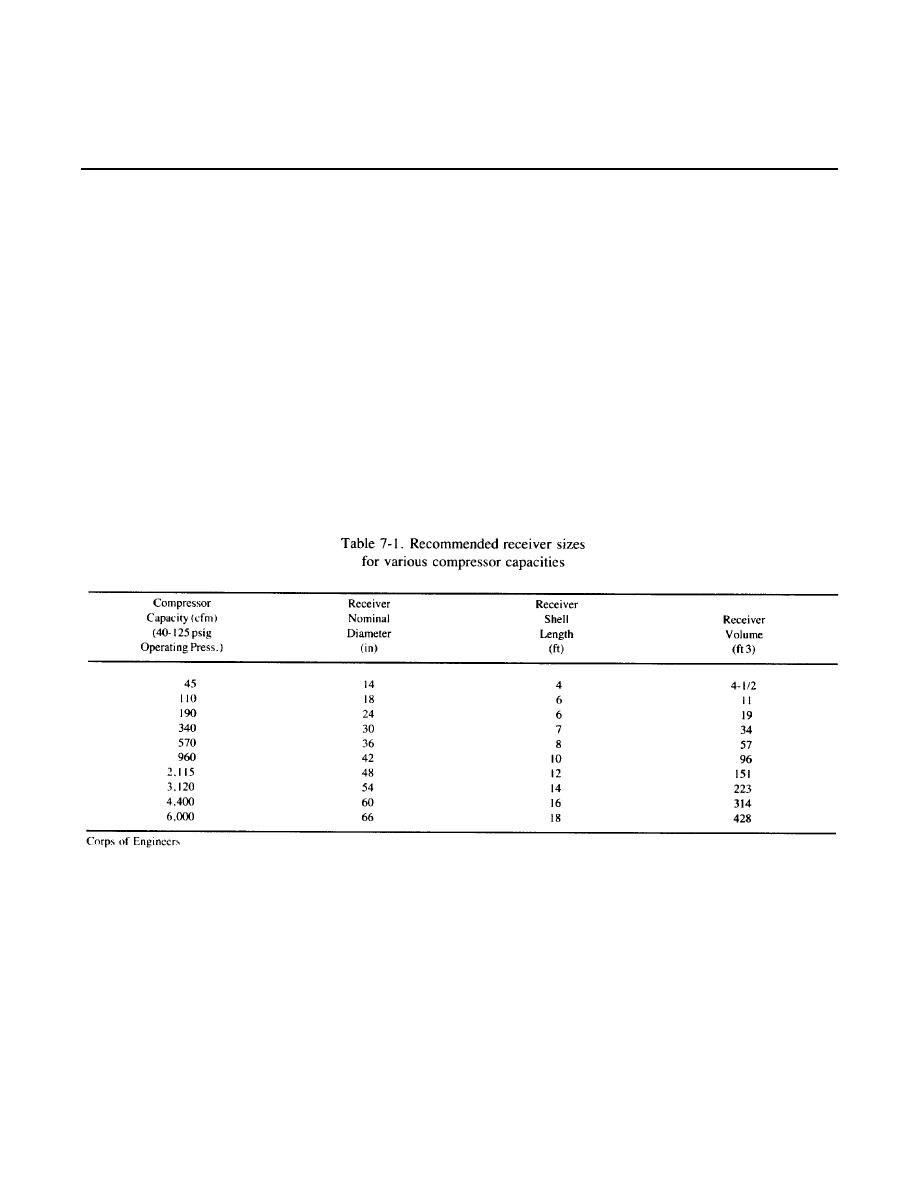

After the air compressor capacity has been established, the

appropriate receiver size can be determined. Table 7-1 lists

the sizes of air receivers in common use and the compressor

capacities recommended for each receiver size, at pressures

of 40 to 125 psig.

7-3.

Installation.

The receiver will be installed on an equipment pad to keep

it dry. Adequate space around the unit is needed for draining,

inspection, and maintenance. When the receiver is located

outside, the safety valve and pressure gauge will be installed

indoors to prevent freezing, and the associated outdoor pip-

ing will be heat traced and arranged to drain back to the

receiver. Where automatic condensate traps are used with

receivers located outdoors, the traps will be located indoors

and the outdoor piping heat traced or the traps and piping

located outdoors will be provided with electric heat tape to

protect them from freezing.

7-1

Previous Page

Previous Page