TM 5-810-15

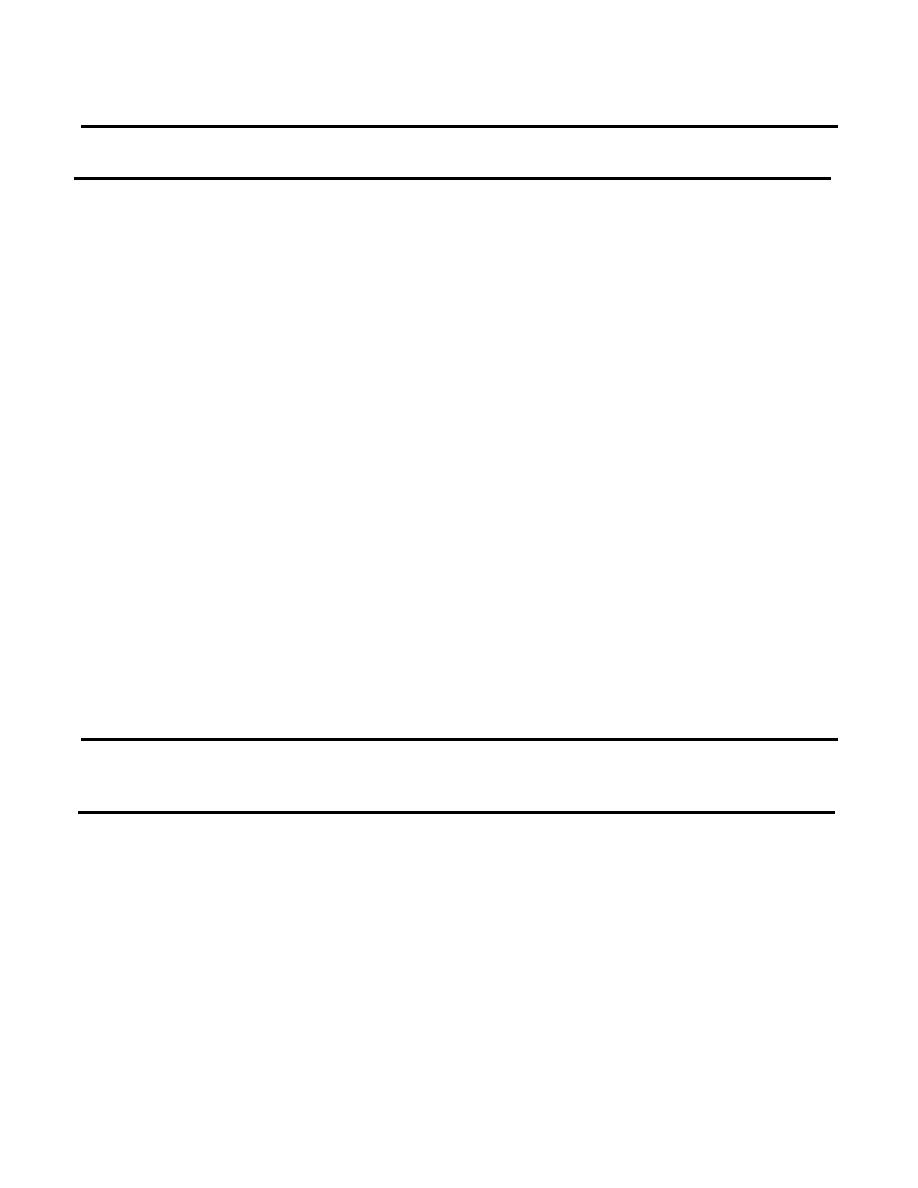

Table 3-6. Stoker Selection Factors.

Vibrating

Traveling

Traveling

Grate Stoker

Grate Stoker

Chain Grate

Stoker

Crossfeed

Spreader

Crossfeed

Spreader

Crossfeed

Feed

Feed

Applicable

100,000-

20,000-

100,000-

50,000-

20,000-

Boiler Size, pph

150,000

150,000

250,000

250,000

75,000

Maximum Grate

400,000

600,000

450,000

750,000

450,000

Heat Release,

Btu/ft2-hr

Maximum Furnace

25,000

25,000

25,000

25,000

25,000

Heat Release,

Btu/ft3-hr

Coal Parameters

0-10

0-10

2-15

0-10

2-15

Moisture %

Volatile

Matter %

30-40

30-40

30-45

30-40

30-45

Fixed Carbon %

40-50

40-50

40-55

40-50

40-55

Ash %

5-10

5-10

6

5-15

6

Btu/lb (Mm)

12,500

11,000

11,000

Free Swelling

5

Index (Max)

Ash Softening

2,300

2,300

2,200

2,300

1,900

Temp, F (Reducing

Stimulus)

Coal Size

1"x0"

1-1/4"x3/4"

1"x0"

1-1/4"x3/4"

1"x0"

Max Fines thru

1/4" Screen Max

40%

50%

60%

40%

60%

Stoker Turndown1

3:1

3:1

3:1

3:1

3:1

(Stable Fire)

Particulate

1.0-1.5

1.4-10

0.6-1.5

1.4-10

0.6-1.5

Emissions

106 Btu

1

To achieve this turndown rate, reference should be considered in the construction of the boiler for either membrane or welded

wall construction or tube and tile type construction. Note some loss in boiler thermal efficiency will occur at lower loads.

Note: Coal sizing and quality have a direct influence on the efficiency of stoker fire boilers. These selection factors do not apply

to those western fuels which have high moisture 25 percent or more content and have a lignite type ash characteristic.

air which controls the velocity of solids through the

3-14.

Overfire air.

combustor. Ash must be removed from the bottom

a. General. Overfire air is the ambient air sup-

of the combustor to control solids inventory, bed

plied by either the FD fan or a separate fan that

quality, and prevent agglomeration of solids.

may also be used for fly ash reinjection and is used

Arrangement of tuyeres or air distribution devices

on all types of stoker fired boilers. The purpose is

must direct ash flow toward bed drains. Figure 3-

to aid combustion and to insure the coal particles

13 shows the major ACFB boiler components.

are as completely burned as possible.

b. Upper combustor and transition zone. The

b. Port location. Overfire air ports are located on

upper combustor is waterwall design. Solids and

either or both the front and rear furnace walls.

gases leave the combustor through a transition

section which must account for three dimensional

3-15. Atmospheric circulating fluidized bed

thermal expansion between the major boiler com-

(ACFB) boiler components.

ponents.

a. Lower combustor. Fuel is fed into the refrac-

c. Solids separator. The transition section with

tory lined lower combustor section where fluidizing

expansion joint connects the combustor to a solids

air nozzles on the floor of the combustor introduce

separator. Two different separator designs include

3-19

Previous Page

Previous Page