TM 5-810-15

Example:

Input-MB/hr

Effcy.

Load

Fuel Cost

Fuel Cost

Increase

Factor

Dollars

Savings

x Percent

x Hours/year

x Per MB

= Per Year

Economizer

140

x 0.06

x 7,000

x 2.00

= 7,600

example*

*Example assumes 100,000 lb/hr capacity, 140 MB/hr full load input, 6 percent efficiency increase with economizer, fuel cost

.00/MB, and MB = Million Btu*s.

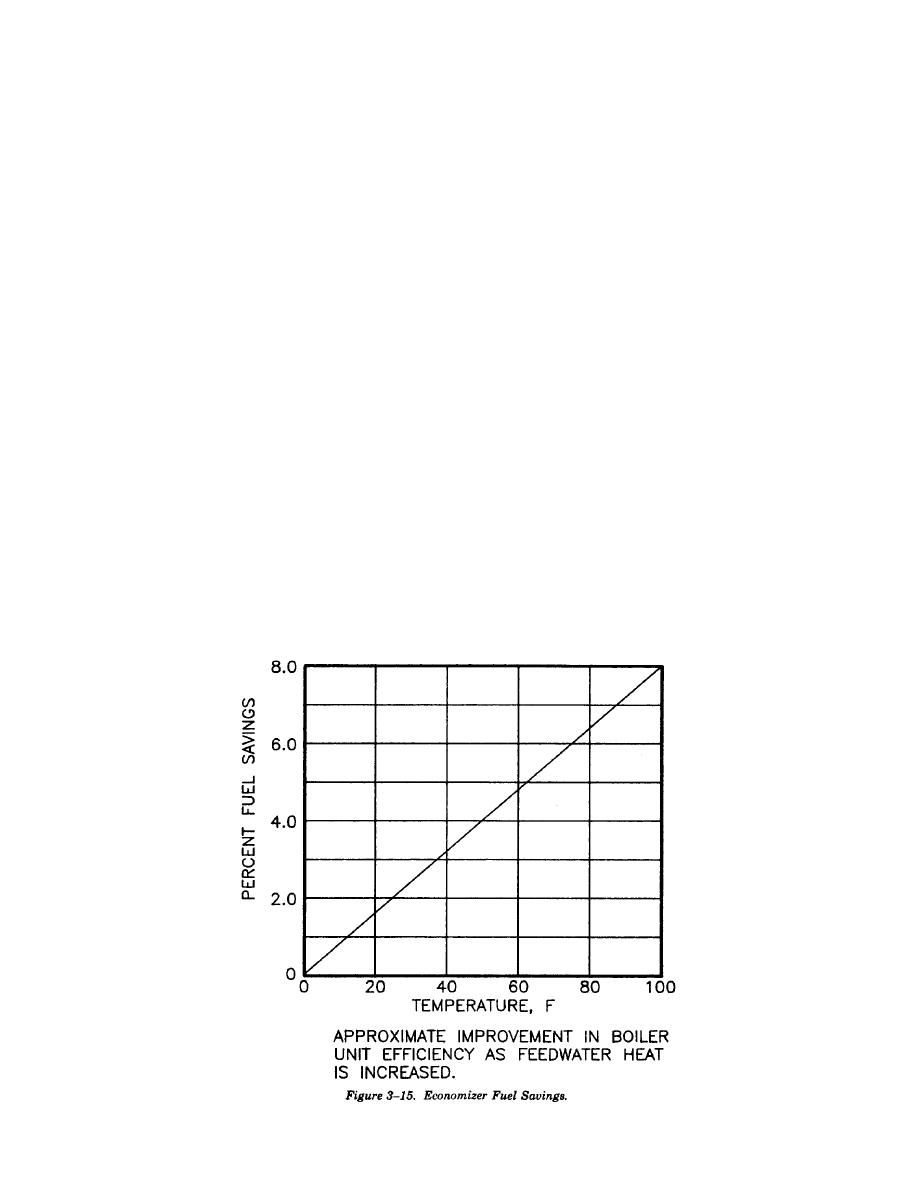

Refer to figure 3-15 for fuel savings based on

related system. The cost of water treatment for the

reduction of exit or flue gas temperature. Normally

steam consumption by the sootblowers is an evalu-

an economizer is less costly and requires less space

ation factor.

f. Boiler casing or setting. The boiler casing or

than an air heater.

e. Sootblowers. Sootblowers are used on all

setting is the most visible component of the unit

heavy oil and coal fired boilers to clean ash

and if not properly designed may be the source of

deposits from furnace, boiler and superheater sur-

excessive maintenance costs and loss of boiler

faces in addition to economizers and air heaters.

efficiency.

Sootblowers will be spaced as specified by the

(1) The term boiler setting was originally

boiler manufacturer to maintain unit efficiency and

applied to the brick walls enclosing the furnace and

prevent coal ash pluggage. Ash deposits on the

heating surfaces of the boiler. Since the boiler

tubes may bridge the space between tubes unless

settings and casing have been the source of a large

stopped before such pluggage occurs. Soot-

portion of boiler related maintenance and operating

blowers are used to keep the tubes clean in order to

(heat loss) costs, a great deal of attention and

maintain tube cleanliness and hence efficiency.

improvements have taken place. This is particularly

(1) Sootblowers may be either steam or air

true of the recent past during which time boilers

blowing.

became so large that heat losses and maintenance

(2) Unless water scarcity is an overriding

costs would have been totally unacceptable. As the

factor, only steam should be used due to capital

technology of water treatment plus boiler design

and operating costs of an air compressor and its

and manufacturing improved, water cooled furnace

3-23

Previous Page

Previous Page