TM 5-810-15

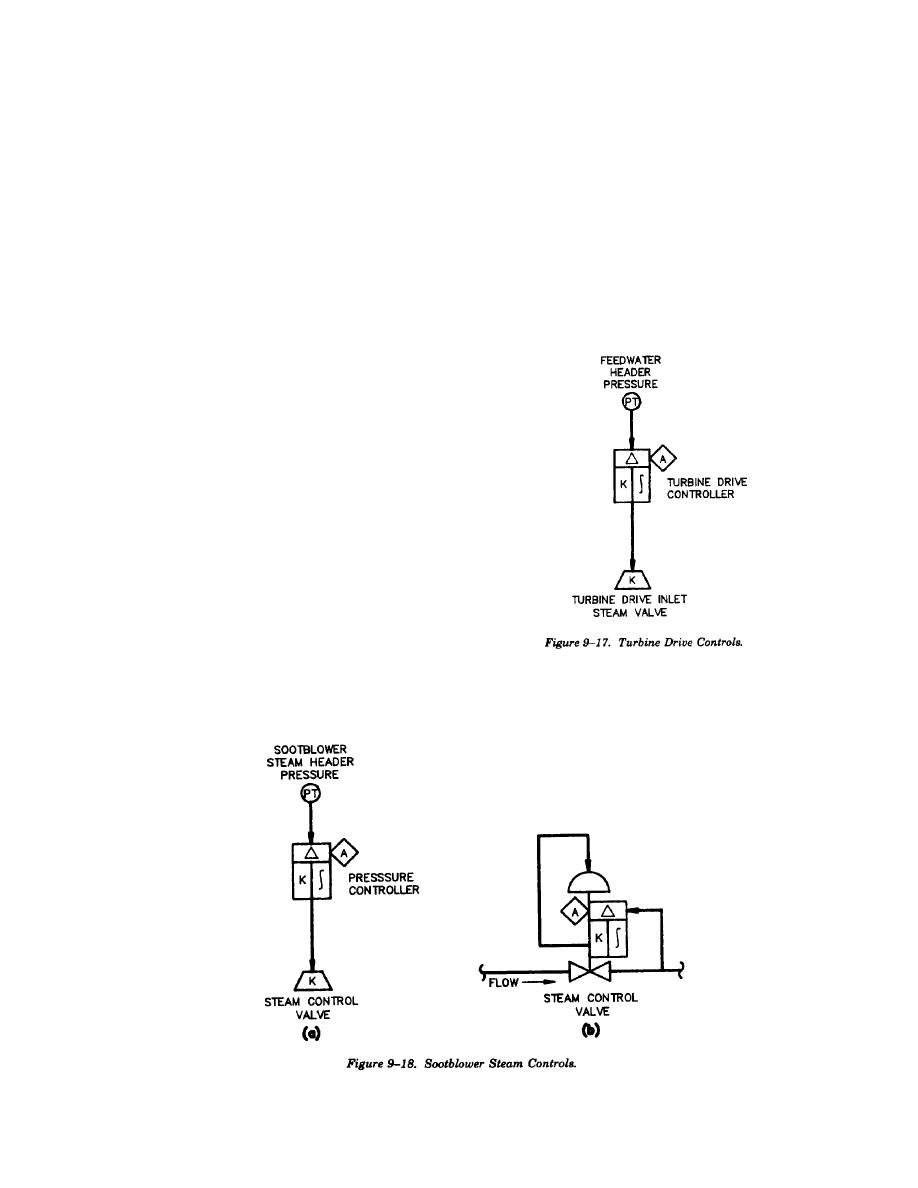

(1) Turbine drives. The boiler feed pump tur-

(4) Deaerator. The DA steam controls are a

bine drive is controlled by feedwater header pres-

pressure control system to maintain DA pressure.

sure. The steam control valve on the turbine drive

A single element loop with feedback as shown in

inlet is controlled by a pressure transmitter on the

figure 9-20 is adequate for controlling DA pres-

feedwater header acting through a controller as

sure.

(5) Feedwater heater. The feedwater heater

shown in figure 9-17. The setpoint pressure will be

lower than the normal operating feedwater pressure

controls as shown in figure 9-21 are used to protect

to prevent turbine drive operation during normal

the economizer against acid condensation. The

operating conditions.

economizer outlet gas temperature and economizer

(2) Sootblowers. Sootblower steam controls

inlet feedwater temperature are averaged. The

are normally a pressure control system to maintain

average is used to control the feedwater

the proper steam pressure at the sootblower inlet.

temperature by regulating the steam input to the

If remote indication of the sootblower steam header

feedwater heater.

pressure is desired a transmitter and controller will

be used as shown in figure 9-18(a). If remote

indication is not required a pressure controller

mounted on the control valve can be used as shown

in figure 9-18(b).

(3) Steam coil air heater. The steam coil air

heater controls are based on maintaining the flue

gas leaving the air heater above the acid dew point

temperature. This is accomplished by using an

average cold end temperature control system as

shown in figure 9-19. Air heater average inlet air

temperature and average gas outlet temperature are

calculated. These two signals are averaged to arrive

at the average cold end temperature, which is used

to control the steam coil control valve. Also, the

control system should include an interlock that

opens the steam coil control valve 100 percent

when the ambient air is below a set temperature,

usually 35 degrees F.

9-17

Previous Page

Previous Page