TM 5-810-15

energize-to-trip. The energize-to-trip philosophy is

Regardless of the level of automation incorporated

more desirable since it reduces nuisance trips, is

into the burner controls, the system logic must

operable on loss of power, and is more reliable.

insure that the operator commands are performed

(3) Flame detection and management. Stoker

in the correct sequence with intervention only when

fired boilers do not utilize flame detection or flame

required to prevent a hazardous condition.

management. Pulverized coal and gas/oil fired

Pulverized coal burner controls must provide the

systems do require flame detection, which is the

proper sequential logic to completely supervise

key to proper flame management. The basic re-

burner startup and operation including coal feeders,

quirements of flame detectors are detection of the

pulverizers, air registers, ignitors, and flame

high energy zone of a burner flame, ability to

detectors. Gas/oil burner controls must provide the

distinguish between ignitor and main flames, and

proper sequential logic to completely supervise

discrimination between the source flame, adjacent

burner startup and operation including gas/oil fuel

flames, and background radiation. Ultraviolet (UV)

valves, air registers, ignitors and flame detectors.

detectors are suited for flame detection of gas or

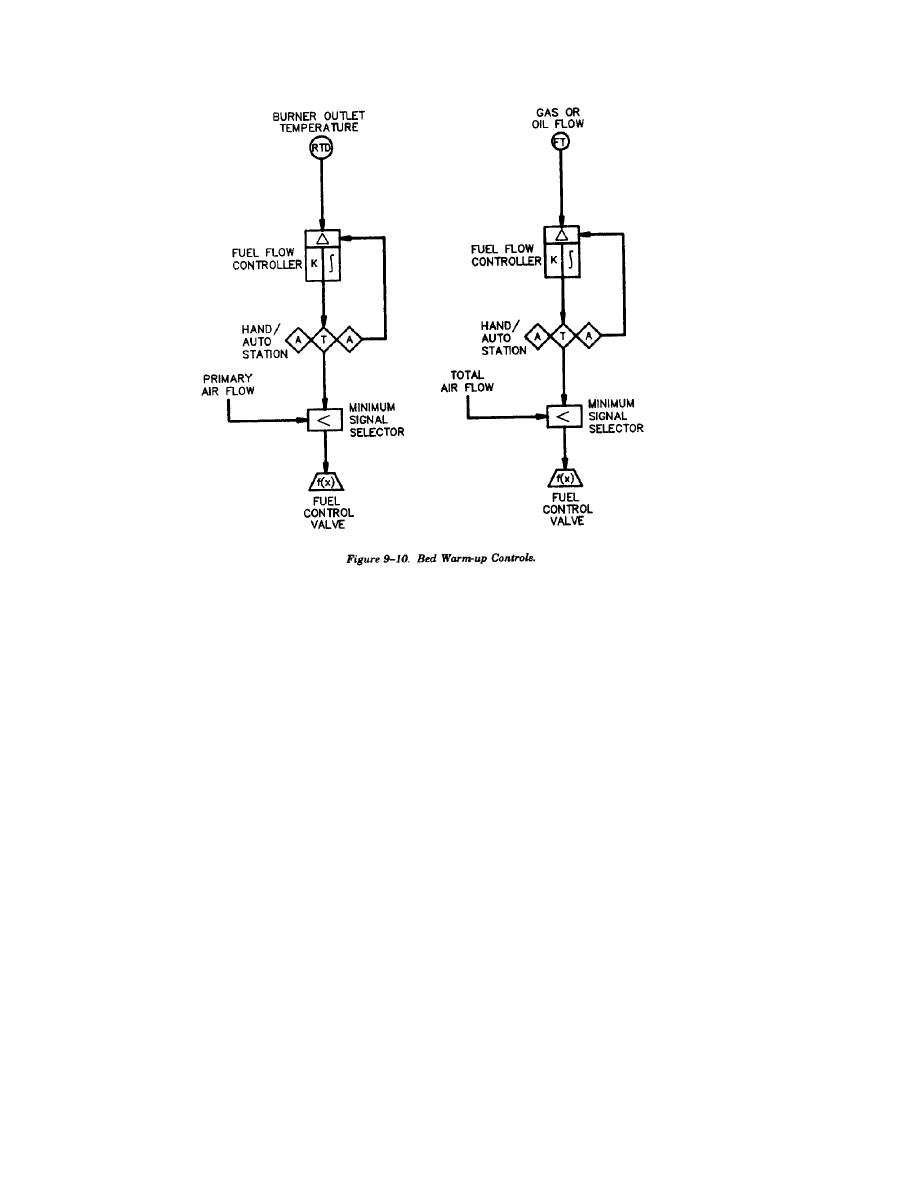

The ACFB boiler includes utilizing a main gas

light oil ignitor and main gas flames. Infrared (IR)

burner or gas lances and ignitor system to warm the

detectors are used for pulverized coal flames. Self

boiler and bed temperature above minimum

checking or redundant detectors should be used to

required for solid fuel firing. This burner operation

ensure reliability. Location of the flame detectors is

is identical to a gas/oil burner operation. The

critical to proper flame management and must be

ACFB boiler does not have a main fuel burner;

given careful consideration. Flame detection

however, the introduction of fuel is completely

systems will be on-off type based on the presence

supervised to provide the proper sequence for

or absence of flame.

purge, ignitors, warm-up burners, flame detection,

(4) Burner controls. Burner controls are the

coal feeders, sorbent feeders and bed temperature

permissives, interlocks, and sequential logic which

monitoring. Note the bed temperature monitor

are required for safe startup and operation of

insures that adequate temperature is present to

pulverized coal, ACFB and gas/oil burners. Burner

ignite the solid fuel. Adequate bed temperature

controls range from manual to fully automatic.

9-12

Previous Page

Previous Page