TM 5-810-15

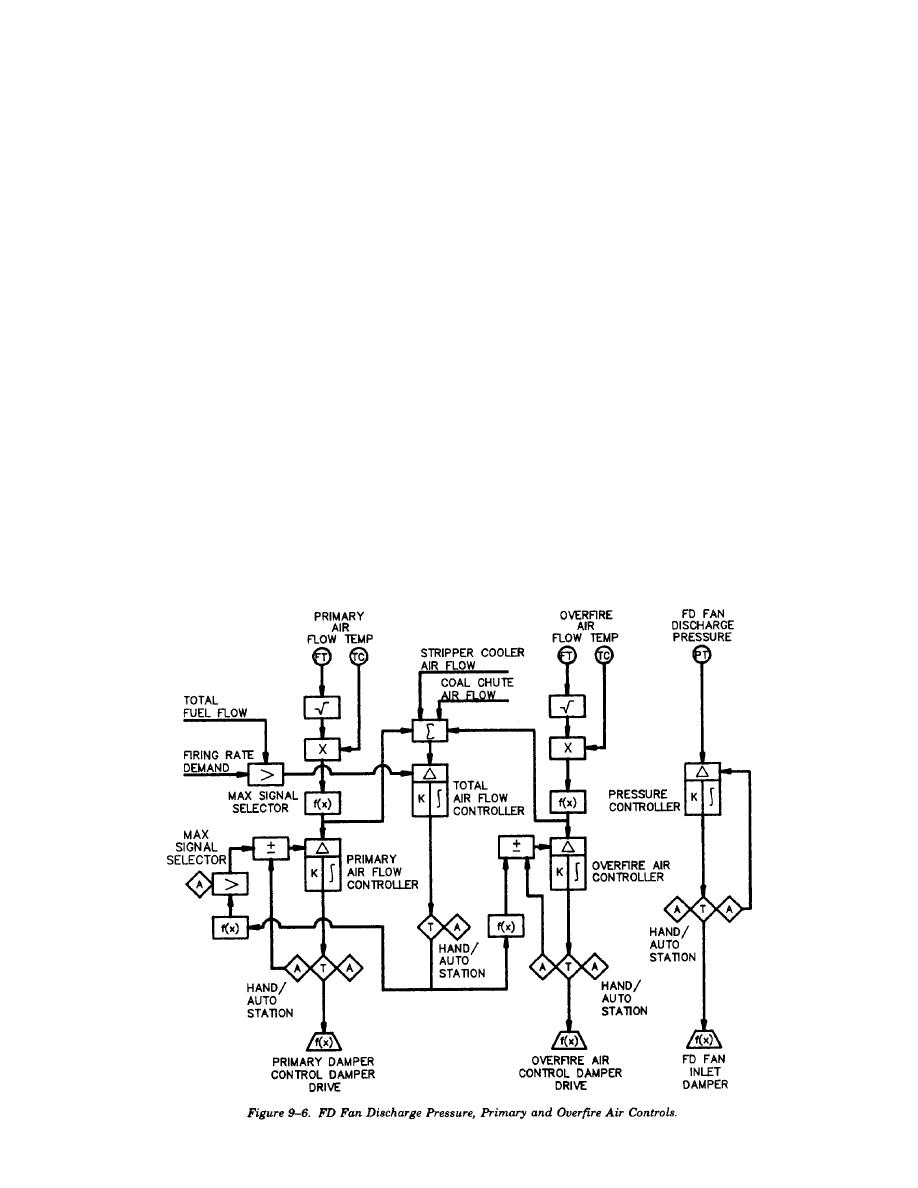

Air supply is maintained by modulating the FD fan

characterized based on load to obtain the proper

and primary air fan inlet vanes or dampers to

primary-to-overfire air flow ratio. The upper over-

maintain pressure in the FD fan outlet duct.

fire air dampers are closed below 50 percent load.

(3) Combustion air flow measurement. Accu-

The primary air controller setpoint is low limited by

rate combustion air flow measurement is also

a minimum primary air setpoint. Each primary and

important in combustion control systems for ACFB

upper air flow controller compares measured air

boilers. Measurement of primary air flow, overfire

flow to setpoint. The controller output becomes the

air flow, stripper cooler air flow, and coal chute air

demand to its respective air flow control damper.

flow will be measured with a venturi section or air

All air flow measurements should be temperature

flow element in the ductwork to the various

corrected. Furnace exit gas temperature should be

equipment. The design pressure differential pres-

monitored and at high temperature alarmed to

sure across the air flow elements will be not less

allow the operator to make the proper air flow

than 2-inches wg at full load. The transmitters

adjustment to bring the temperature back to

selected for primary air flow and secondary air flow

normal. A bias adjustment normally is provided for

will be differential pressure transmitters that are

each controller.

(5) Furnace bed inventory control and solids

accurate in the range of differential pressure

cooler temperature, air flow and spray water con-

developed by the flow elements.

(4) Primary and overfire air flow control. Fig-

trol. Furnace bed inventory control requires re-

ure 9-6 shows the primary and overfire air flow.

moval of excess bed material from the furnace. The

The firing rate demand signal serves as an index for

solids cooler cools the excess bed material to a

air flow demand. The fuel feed signal and firing rate

temperature which allows it to be disposed of via

demand signal are cross limited by a high selector

the ash system. Solids are removed from the

to serve as the setpoint for the total air flow

furnace either by operator action or automatically

controller. The output of the total air flow

on high furnace plenum pressure. The furnace bed

controller becomes the setpoint for the primary and

static pressure, total furnace differential pressure,

overfire air flow controllers. The setpoint is

9-8

Previous Page

Previous Page