TM 5-810-15

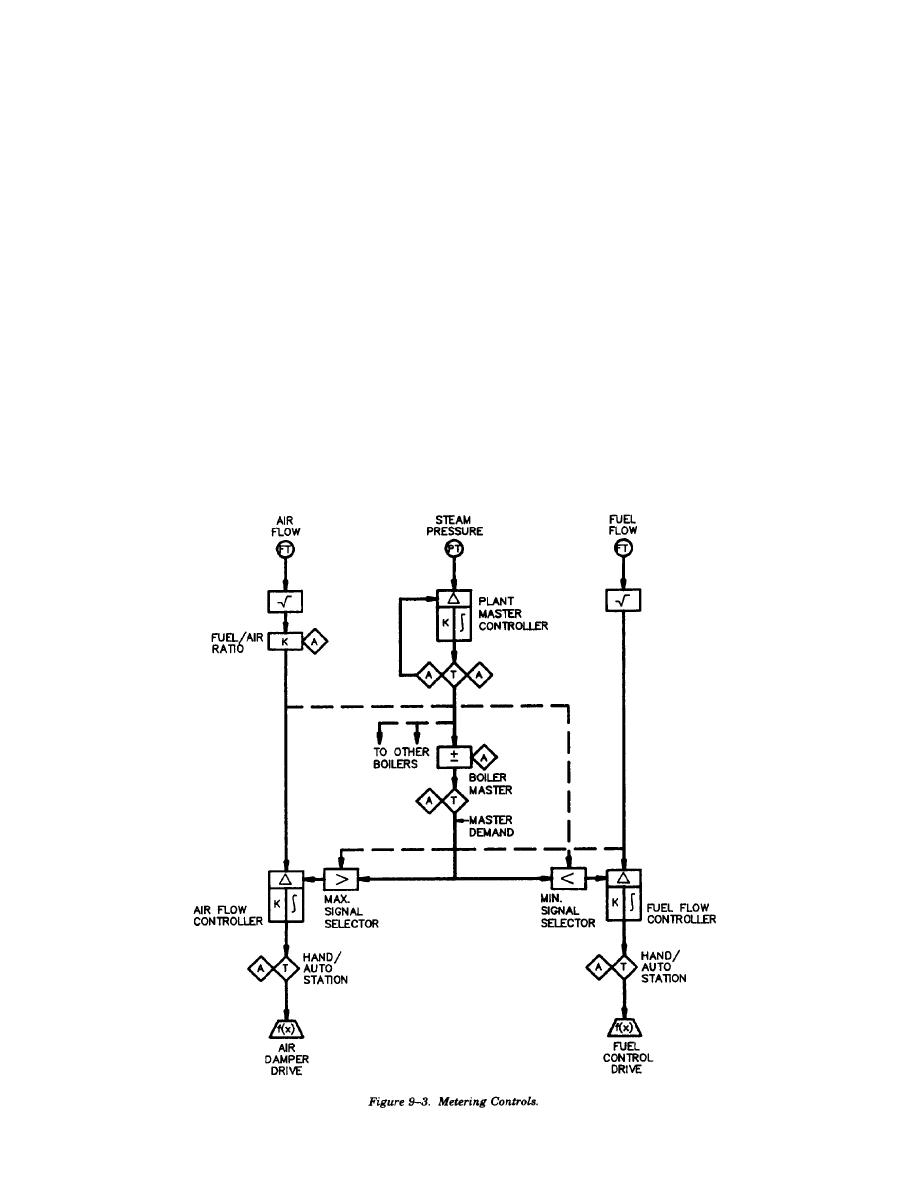

(2) Metering control. Metering control

e. Stoker system controls.

(1) Fuel flow control. The components of a

systems regulate combustion based on metered fuel

and air flows as shown in figure 9-3. The master

stoker system must respond to the fuel flow de-

demand developed from steam pressure error

mand signals generated by the combustion control

establishes the setpoints for fuel and combustion air

system. For spreader stokers the coal feed to the

flows at the controllers. The controllers drive the

overthrow rotor will vary with the demand signal.

final control elements to establish proper fuel and

Grate speed on traveling grate and traveling chain

flows which are fed back to the controllers.

grate stokers will respond to the demand signal.

Maximum and minimum signal selectors are used to

The frequency and duration of vibration cycles on

prevent the fuel input from exceeding available

vibrating grate stokers will vary with the demand

combustion air on a boiler load increase and to

signal. In all cases the relationship between fuel

prevent combustion air from decreasing below fuel

flow and unit load will be determined for use in the

flow requirements on load reduction. This system

combustion control system to properly control fuel

is a cross-limiting flow tie back system with air

flow in response to the demand signal.

(2) Combustion air control. The combustion

leading fuel on load increase and fuel leading air on

load reduction. This system is applicable to gas and

air flow is normally controlled at the FD fan. Two

oil, pulverized coal, and ACFB fired units.

methods that are commonly used are control of

d. System selection. Table 9-1 summarizes the

inlet vanes on the FD fan or control of the FD fan

combustion control systems discussed and their

inlet damper. If a metering control system is used

application to the various types of boilers.

the combustion air flow should be measured down

9-4

Previous Page

Previous Page