TM 5-810-15

ized coal fired and ACFB boilers. Variations in the

allows the operator to load the boiler over its

steam pressure setpoint adjust the fuel flow input.

complete operating range. The fuel valves and air

Since steam flow is directly related to heat release

damper are operated by the same drive through a

of the fuel, and because a relationship can be

mechanical linkage. The gas and oil valves include

established between heat release and combustion

cams which are adjusted at start up to maintain

air requirements, steam flow can be used as an

proper fuel air ratio over the operating range of the

index of required combustion air. Note however

boiler. Parallel positioning systems with fuel/air

that this relationship is true only at steady load

ratio control as shown in figure 9-2(b) are suitable

conditions.

for use on gas/oil and stoker fired units. This

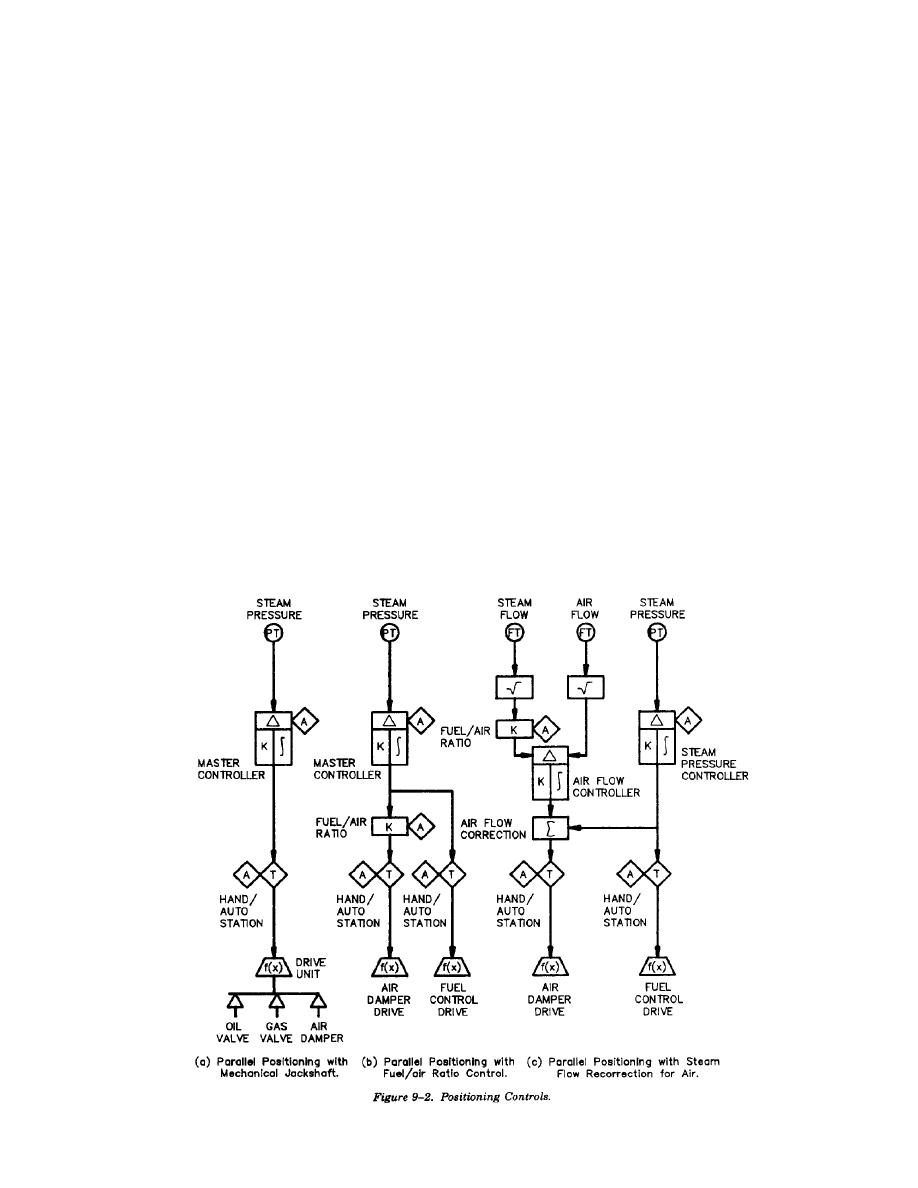

c. System categories. Combustion controls can

system allows the operator to adjust the fuel/air

be further divided into two categories within the

ratio for the entire load range of the boiler. The

basic types: positioning control and metering con-

addition of steam flow correction of air flow to

trol, as shown in figure 9-2.

parallel positioning with fuel/air ratio control

(1) Positioning control. Positioning systems

creates a system suitable for use on ACFB, gas/oil

require that the final control elements move to a

and pulverized coal fired units as shown in figure 9-

preset position in response to steam pressure

2(c). This system uses variation of steam pressure

variations from a setpoint. Series positioning con-

from a setpoint to initially control fuel and air

trol will not be covered here since it is only used on

inputs. The system recorrects combustion air flow

very small boilers operating at constant loads.

using steam flow as a setpoint for air flow, since

Parallel positioning systems that use a mechanical

steam flow is a function of fuel Btu input (inferred

jackshaft to simultaneously position fuel feed and

fuel flow). This system relates directly to a series-

air flow from a single actuator apply to packaged

parallel type control with the addition of a feed-

type gas/oil fired boilers in the 20,000 to 70,000

forward signal from the steam pressure controller

pph size and is shown in figure 9-2a. This system

to the combustion air control.

9-3

Previous Page

Previous Page