TM 5-810-15

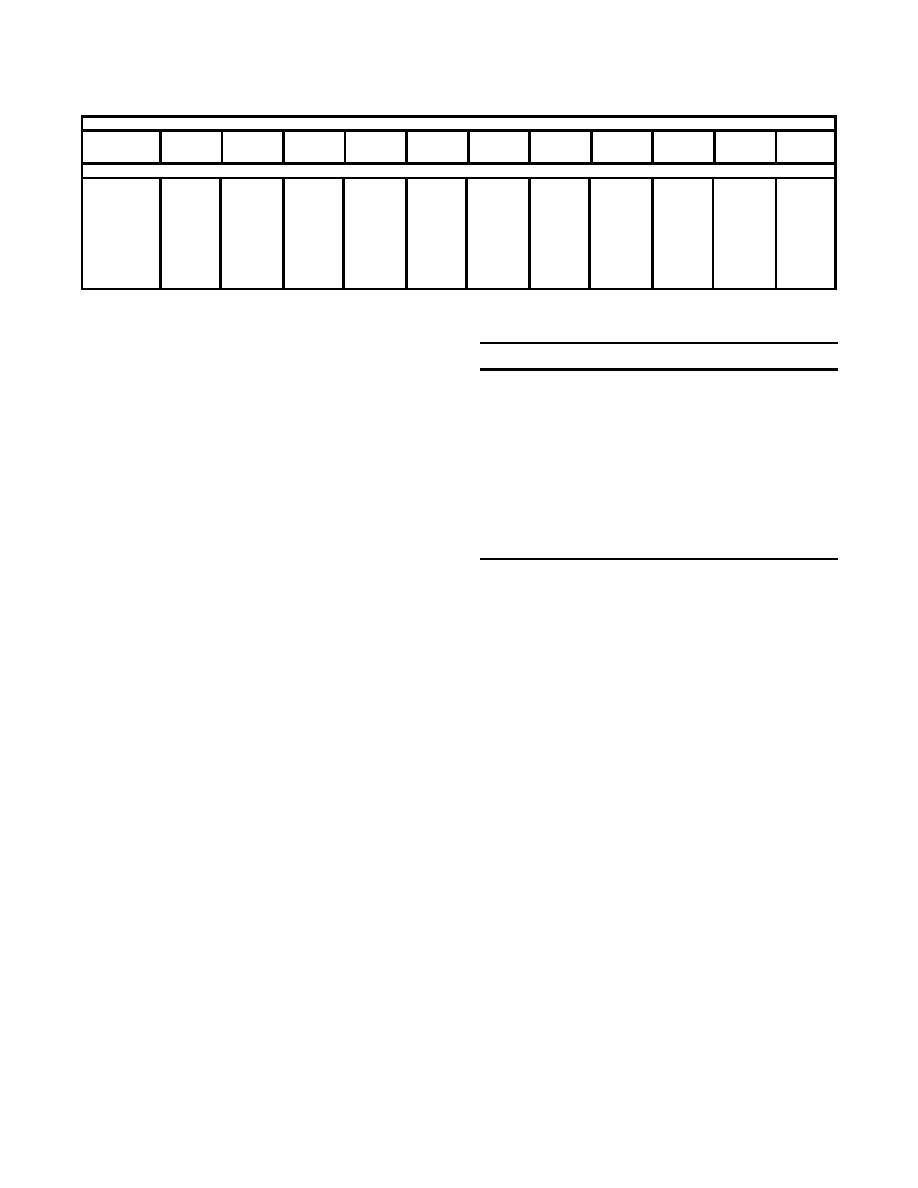

Table 8-5. Recommended Economic Thickness for Pipe Insulation. (Continued)

Temperature of pipe F

Nominal Pipe

size, in.

100-199

200-299

300-399

400-499 500-599 600-699 700-799

800-899

900-999 1000-1099 1100-1200

UTILITY--STEAM GENERATION

7

1

1

2

2

2

2

3

3

3

4

4

8

1

1

2

2

2

2

3

3

4

4

4

9

1

1

2

2

2

3

3

3

4

4

5

10

1

1

2

2

3

3

3

4

4

4

5

11

1

1

2

2

3

3

3

4

4

4

5

12

1

1

2

2

3

3

3

4

4

4

5

l4 and up

1

1

2

2

3

3

4

4

4

4

5

8-5. Pipe hangers, anchors and supports.

Table 8-6. Piping Velocity Guidelines.

will be designed to meet ASME B31.1 require-

Fluid

Application

Velocity

ments where applicable. Pipe hangers will be in

Steam

Superheated steam, boiler leads

150-333 fps

accordance with MSS SP-69.

Auxiliary steam, exhaust lines

100-250 fps

b. Spacing. Guidelines for pipe support spacing

and carrying capacities are provided in ASME

Saturated and low pressure steam

100-167 fps

B31.1

Water

Centrifugal pump suction lines

3-5 fps

8-6. Pipe expansion compensation.

Feedwater

8-15 fps

a. Design. The thermally induced expansion of

General service

4-10 fps

piping materials can be compensated for with

Potable water

Up to 7 fps

normal pipe bends and the proper placement of

anchors. The thermal expansion of common piping

without exceeding maximum allowable velocities or

materials is shown in Appendix B of the ASME

causing excessive pressure drops.

B31.1.

e. Sizing calculations. Empirical equations and

b. Expansion devices. When piping system de-

charts have been devised to calculate pressure

sign is unable to compensate for pipe expansion,

drops with reasonable accuracy. The Darcy Equa-

expansion bends or expansion joints will be used.

tion has been shown to produce accurate results.

Expansion joints and bends will conform to ASME

standards.

8-8. Steam traps.

a. Application. Steam traps are devices that are

8-7. Pipe sizing.

used to accomplish the following functions:

a. General. Selection of the proper pipe size for

(1) Allow condensate resulting from loss of

any particular application is dependent upon nu-

latent heat in steam to flow from the steam system

merous variables. Pipe sizing is based on velocity,

to a lower pressure system or to atmosphere.

pressure loss, and friction loss calculations.

(2) Vent air and other gases from the steam

b. Data requirements. In order to properly size

system to maintain steam temperature and reduce

piping, pertinent data must be organized for use in

corrosion.

the required calculations. This data includes pipe

(3) Prevent escape of steam from the steam

material (friction factor), process fluid, flow re-

system.

quirements, design pressures and temperatures,

b. Selection. The factors to be considered when

allowable pressure drop, velocity requirements, and

selecting the proper steam trap include condensate

preliminary piping layout.

load, continuous or intermittent operation, system

c. Velocity guidelines. General guidelines for

pressure, constant or variable pressure and load,

indoor or outdoor installation, failure mode (open

allowable velocities in piping systems are shown in

or closed), air and noncondensible gas venting, and

table 8-6.

resistance to water hammer.

d. Pipe sizing philosophy. Piping will be sized to

c. Design. Trap selection and sizing depends on

obtain a maximum velocity that corresponds to the

many factors. The condensate load on a trap

allowable pressure drop for the system. It is

involves range of load as well as rate of change.

desirable to keep velocities as high as possible

Nearly all traps service a long range. A trap will be

8-11

Previous Page

Previous Page