TM 5-815-1/AFR 19-6

CHAPTER 10

SULFUR OXIDE (SOx) CONTROL SYSTEMS

10-1.

Formation of sulfur oxides (SOx)

(3) When choosing a higher quality fuel, as in

changing from residual to distillate fuel oil,

a. Definition of sulfur oxide. All fossil fuels contain

modest modifications, such as changing

sulfur compounds, usually less than 8 percent of the

burner tips, and oil feed pumps, are required.

fuel content by weight. During combustion, fuel-bound

c. Changes in fuel properties. Consideration of pos-

sulfur is converted to sulfur oxides in much the same

sible differences in fuel properties is important. Some

way as carbon is oxidized to CO2. Sulfur dioxide (SO2)

examples are:

and sulfur trioxide (SO3) are the predominant sulfur

(1) Higher ash content increases particulate emis-

oxides formed. See equations 10-1 and 10-2.

sions.

(2) Lower coal sulfur content decreases ash

fusion temperature and enhances boiler tube

slagging.

b. Stack-gas concentrations. In efficient fuel com-

(3) Lower coal sulfur content increases fly-ash

bustion processes, approximately 95 percent of the

resistivity and adversely affects electrostatic

fuel-bound sulfur is oxidized to sulfur dioxide with 1

precipitator performance.

to 2% being coverted to sulfur trioxide.

(4) Low sulfur coal types may have higher

c. Factors affecting the formation of SOx.

sodium content which enhances fouling of

(1) 503 formation increases as flame temperature

boiler convection tube surfaces.

increases. Above 3,150 degrees Fahrenheit,

(5) The combination of physical coal cleaning

503 formation no longer increases.

and partial flue gas desulfurization enables

(2) SO3 formation increases as the excess air rate

many generating stations to meet SO2

is increased.

standards at less expense than using flue gas

(3) SO3 formation decreases with coarser

desulfurization alone.

atomization.

d. Modification of fuel. Some possibilities are:

(1) Fuels of varying sulfur content may be mixed

10-2.

Available methods for reducing SOX

to adjust the level of sulfur in the fuel to a low

emissions

enough level to reduce SO2 emissions to an

a. Fuel substitution. Burning low sulfur fuel is the

acceptable level.

most direct means of preventing a SOx emissions prob-

(2) Fuels resulting from these processes will

lem. However, low sulfur fuel reserves are decreasing

become available in the not too distant future.

and are not available in many areas. Because of this,

Gasification of coal removes essentially all of

fuel cleaning technology has receive much attention.

the sulfur and liquification of coal results in a

There are presently more than 500 coal cleaning plants

reduction of more than 85% of the sulfur.

in this country. At present, more than 20% of the coal

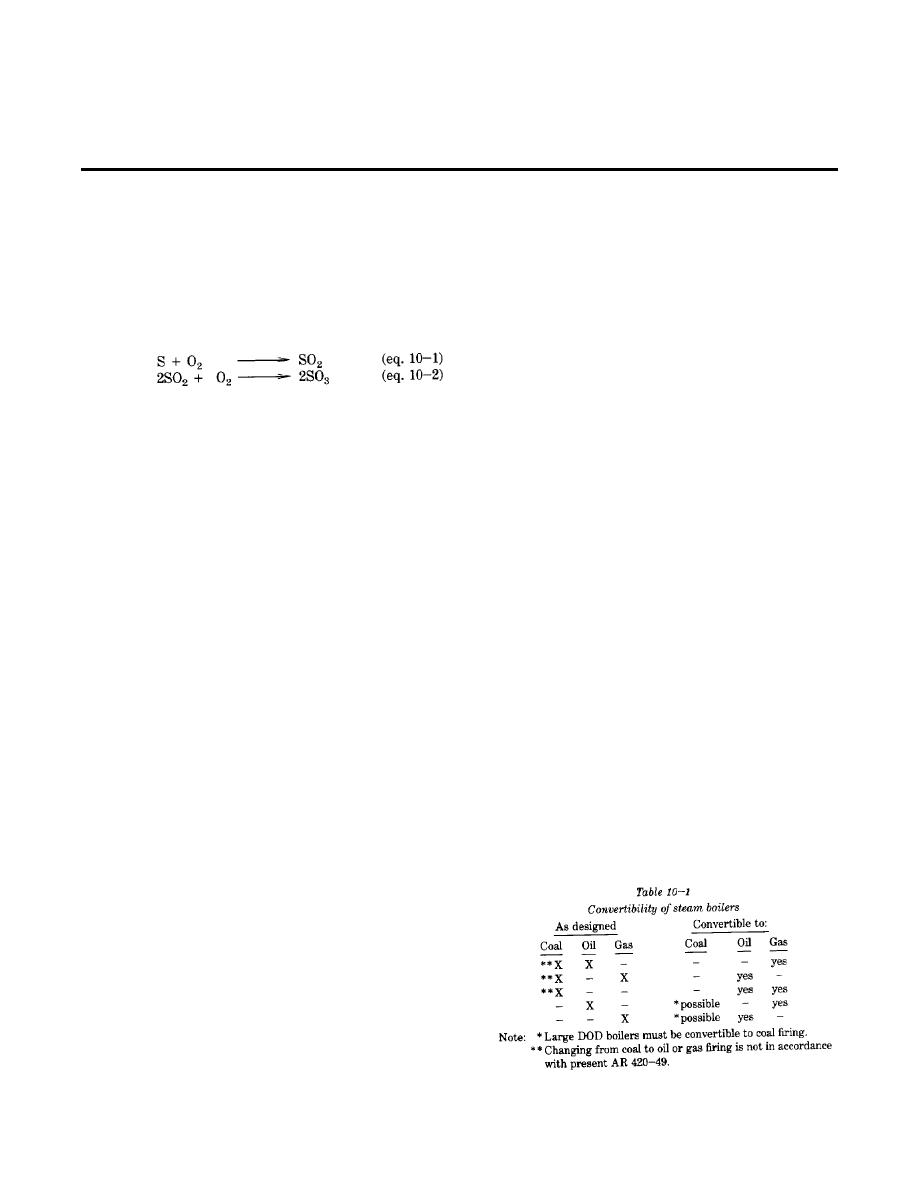

e. Applicability of boiler conversion from one fuel

consumed yearly by the utility industry is cleaned.

Forty to ninety percent of the sulfur in coal can be

can be converted to other type of firing but that policies

removed by physical cleaning, depending upon the type

of the agencies must also be a consideration.

of sulfur deposits in the coal. As fuel cleaning tech-

nology progresses and the costs of cleaning decrease,

fuel cleaning will become a long term solution

available for reducing sulfur oxide emissions.

b. Considerations of fuel substitution. Fuel sub-

stitution may involve choosing a higher quality fuel

grade; or it may mean changing to an alternate fuel

type. Fuel substitution may require any of the following

considerations:

(1) Alternations in fuel storage, handling, prepa-

ration, and combustion equipment.

(2) When changing fuel type, such as oil to coal,

a new system must be installed.

10-1

Previous Page

Previous Page