UFC 3-440-01

14 June 2002

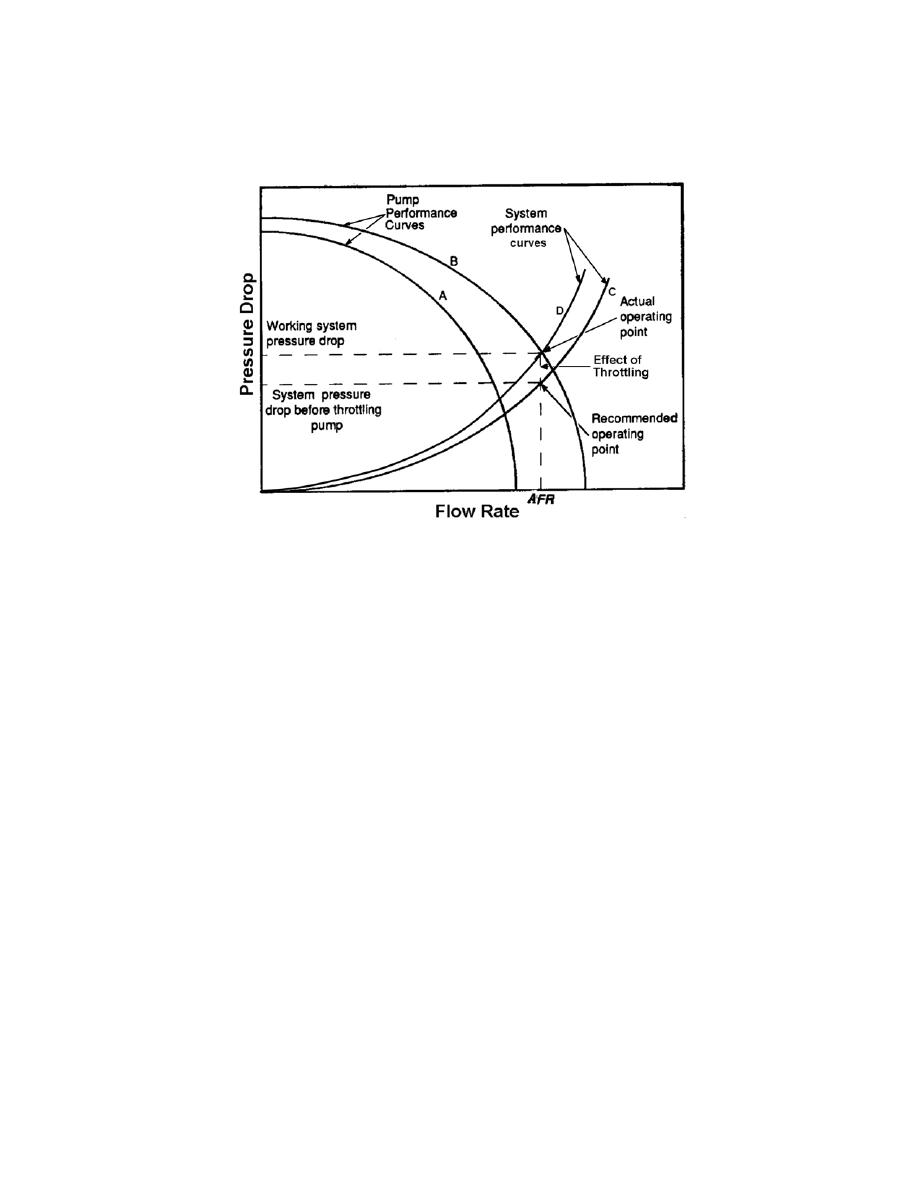

Figure 4-10. Typical Pump and System

Operation Curves

4.4.2.2.1

Component Connections. Major system components, such as the

collector banks, storage tank, heat exchanger, and circulation pumps, should be able to

be valved off and removed for cleaning, repair, or replacement. Installing valves on

both sides of the component usually provides this feature.

4.4.2.2.2

Roof Penetrations. Roof penetrations for the array supply and return

piping and sensor wiring conduit should be designed carefully to prevent leaking and to

account for movement due to thermal expansion. Standard penetration schemes (such

as those used for plumbing system vents) can fail because of the increased

temperature extremes to which solar system piping is subjected.

4-5

CONTROL SUB-SYSTEM. There are four areas concerning the control sub-

system that needs to be addressed during the final design stage. These include

specification of a control unit, location of control sensors, the location of local

monitoring equipment, and measurement of thermal energy delivered by the system.

4-5.1

Differential Temperature Control Unit (DTC). The proper specification of

the differential temperature control unit is important to ensure reliable system

performance. Because the cost of a simple solar system controller is small relative to

the total system cost, a high quality, commercially available unit is recommended. The

controller should include solid-state design with an integral transformer. The designer

should also ensure that the switching relay or other solid state output device is capable

of handling the starting current imposed by the system pump(s). The control unit

should allow the on and off set-points to be variable, and should allow the

instantaneous temperatures of the collector and storage tank to be displayed by the

system operator or maintenance personnel. Faulty sensors are a common cause of

system failure, so it is desirable to choose a control unit that will diagnose and flag open

4-22

Previous Page

Previous Page