UFC 3-535-01

17 November 2005

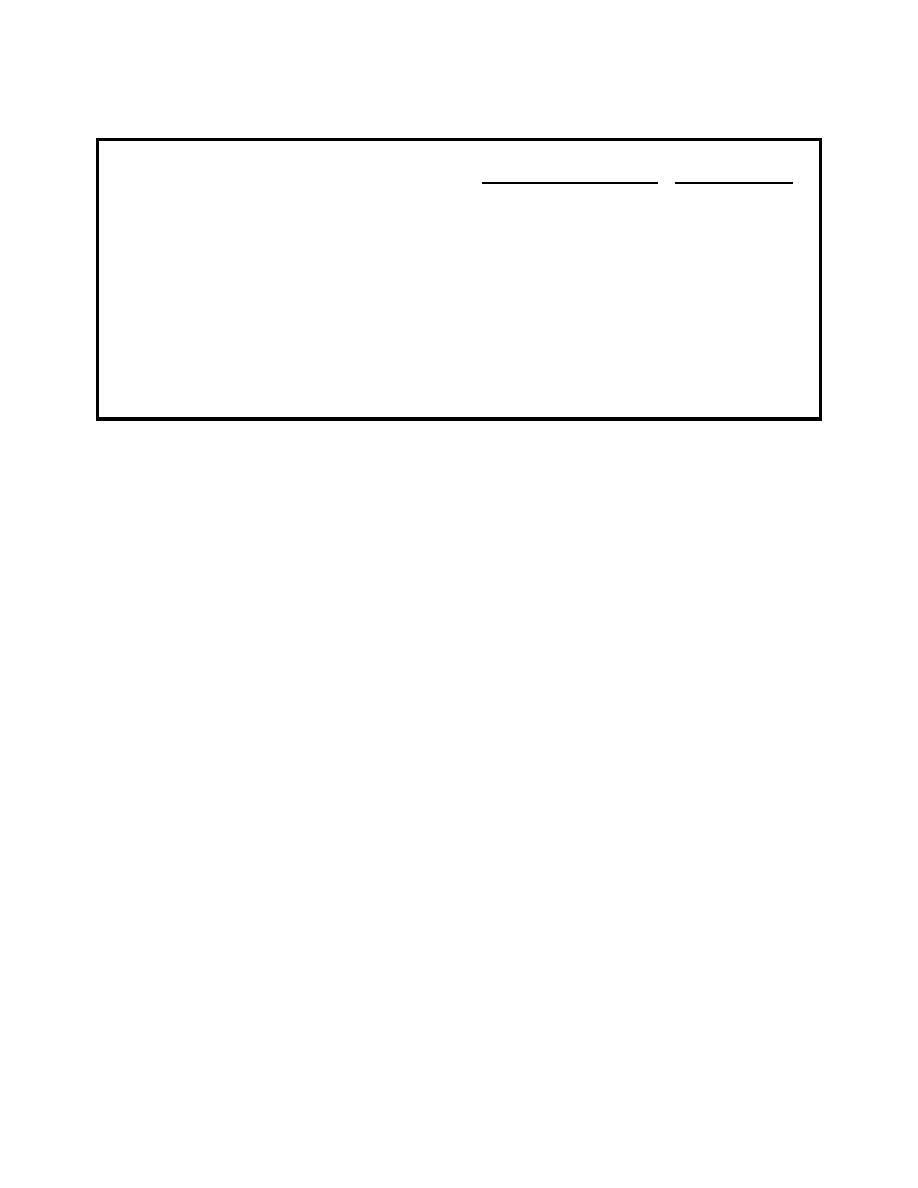

Table 14-9. Cable/Circuit Test Procedures

First Test on

Succeeding

New Circuit

Old Circuit

Complete Approach System (5,000V leads, 500

and 300W transformers)

1.5 x max. working V

1,000V

Touchdown Zone and Center-line Light Circuits

(5,000V leads, 200W transformers)

1.5 x max. working V

1,000V

High Intensity Runway Edge Light Circuits,

(5,000V leads, 500 and 200W transformers)

1.5 x max. working V

1,000V

Medium Intensity Runway and Taxiway Circuits

(5,000V leads and 30/45W transformers)

1.5 x max. working V

1,000V

600 Volt Circuits

1.5 x max. working V

600V

14-5.2.2

The above tests must be performed with a suitable high voltage DC tester

that has a steady, filtered output voltage. The high voltage tester must have an accurate

voltmeter and microammeter for reading the voltage applied to the circuit and the

insulation leakage current.

14-5.2.3

All high voltage tests on airfield lighting circuits must be carefully

supervised by qualified government personnel to ensure that excessive voltages are not

applied to circuits.

14-5.2.4

During the last minute of the above tests, the insulation leakage current in

microamperes for each complete circuit must not exceed the following value calculated

for each circuit:

14-5.2.4.1 Allow 2 microamperes for each 30/45, 100, 200, 300 and 500W series

transformer tested at voltage shown in Table 14-9.

14-5.2.4.2 Allow one microamperes for each 300 feet of cable tested at voltage

shown in Table 14-9. This value includes allowances for the normal number of

connectors and splices.

14-5.2.4.3 Using a 1000 volt DC crank-type megger, each circuit must measure

above 30 megohms to be satisfactory.

14-5.2.5

If the leakage current exceeds the value calculated as outlined above, the

circuit must be sectionalized and the above test repeated for each section. Defective

components must be located and repaired or replaced until the entire circuit passes the

test.

14-5.2.6

Make sure the test voltage specified in paragraph 14-5.2.1 is applied to a

circuit in the final acceptance test. The voltage should be adjusted so the voltmeter

reads the desired value before the leakage current is read. If there is a difficulty in

240

Previous Page

Previous Page