MIL-HDBK-1025/10

4.4.2 Safety Equipment and Tools. When working around electrical lines and

equipment, temporary protective insulation is provided by using the insulating properties of

rubber goods, plastic guard equipment, and live-line tools. Platforms and aerial lift bucket trucks

provide insulated supports for positioning a worker.

4.4.2.1 Rubber Protective Equipment. Equipment consists of gloves, sleeves, blankets,

covers, and line hose. All items should meet or exceed requirements of the applicable ASTM F

18 series specification and be suitable for the working voltage level (Table 3). Rubber goods

should be visually inspected before use. An air test of gloves is also required. Workers should

periodically review ASTM F 1236, Guide for Visual Inspection of Protective Rubber Products.

Electrically retest rubber goods issued for service based on work practice and test experience

intervals. Retesting intervals should not exceed 6 months for rubber gloves and 12 months for

rubber sleeves and blankets. Retest any rubber goods where there may be a reason to suspect the

electrical integrity of the equipment. Electrically retest items that have been removed from

storage for issue for service, unless they were electrically tested at the time of placement into

storage and storage time does not exceed 12 months.

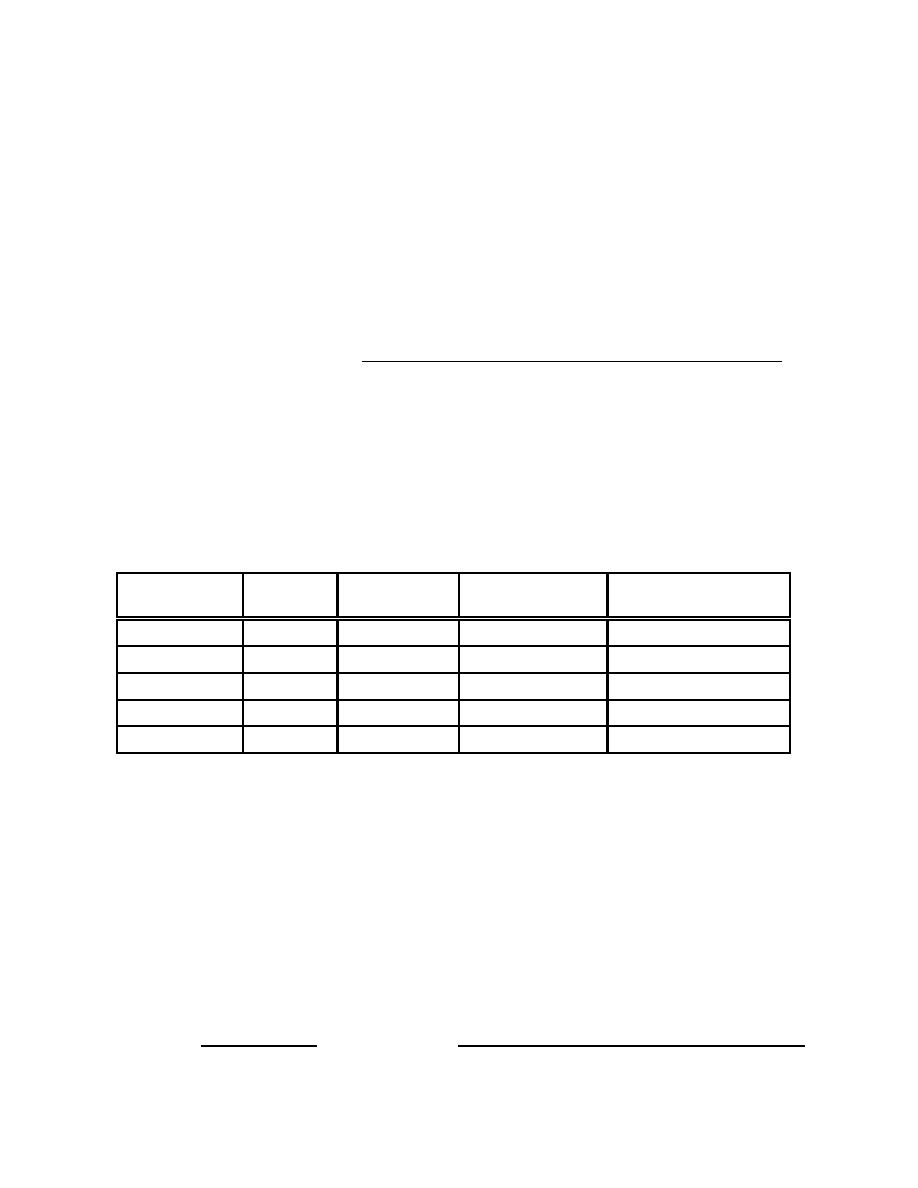

Table 3

ASTM F 18 Rubber Goods1

Minimum distance2

Maximum use,

Proof test

Class

Color label

ac volts

ac volts

millimeters (inches)

1,000

0

Red

5,000

25 (1)

7,500

1

White

10,000

25 (1)

17,000

2

Yellow

20,000

50 (2)

26,500

3

Green

30,000

75 (3)

36,000

4

Orange

40,000

4 (100)

1

Wear leather protectors over rubber gloves.

2

Minimum length of exposed rubber glove above the leather protector.

4.4.2.2 Plastic Guard Equipment. This equipment is rated for momentary (brush)

contact protection. Guards include those installed on conductors; connecting covers used over

lines, insulators, buses, and structures; and apparatus guards used over poles, crossarms, cutouts,

and switchblades. See Tables 33 and 34 in section 5. Electrically retest plastic guard equipment

based on work practice and test experience. Electrically retest items where there may be a reason

to suspect the electrical integrity of the equipment.

4.4.2.3 Live-Line Tools. Comply with the requirements of OSHA standard 29 CFR

1910.269(j), Live-Line Tools. ANSI/IEEE 935, Guide on Terminology for Tools and Equipment

14

Previous Page

Previous Page