TM 5-811-7

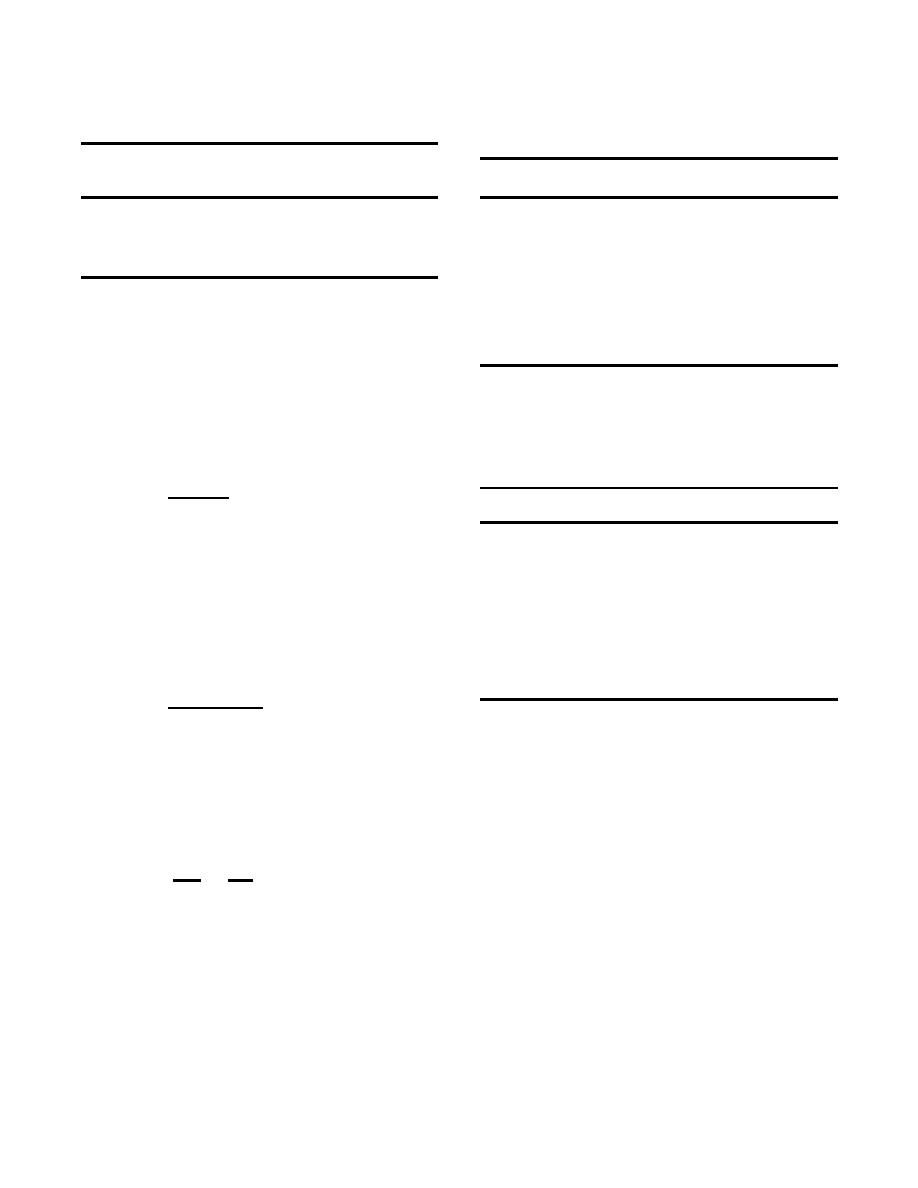

Table 2-4.

Weights and dimensions of selected circular high-

Table 2-5.

Shape functions (K) for impressed current cathodic

silicon chromium-bearing cast iron anodes

protection anodes where L is effective anode length

and d is anode/backfill diameter.

Anode

Anode

Anode

Package

weight

dimensions

surface

area

L/d

K

L/d

K

(lb)

(in.)

size (in.)

(sq ft)

5

0.0140

20

0.0213

6

0.0150

25

0.0224

12

1 x 60

1.4

10 x 84

7

0.0158

30

0.0234

44

2 x 60

2.6

10 x 84

8

0.0165

35

0.0242

60

2 x 60

2.8

10 x 84

9

0.0171

40

0.0249

110

3 x 60

4.0

10 x 84

10

0.0177

45

0.0255

12

0.0186

.50

0.0261

Reproduced from Harco Corporation, Catalog of Cathodic Protection

14

0.0194

55

0.0266

Materials, 1971. Used with permission.

16

0.0201

60

0.0270

(4) Calculate number of anodes needed to

28

0.0207

satisfy manufactuere's current density limitations.

Impressed current anodes are supplied with a

Reproduced from W.T. Bryan, Designing Impressed Current

recommended maximum current density. Higher

Cathodic Protection Systems With Durco Anodes, The Duriron

Company, 1970. Used with permission.

current densities will reduce anode life. To deter-

mine the number of anodes needed to meet the

Table 2-6. Anode paralleling factors (F) for various numbers of

current density limitations, use equation 2-9:

anodes (N) installed in parallel

I

N'

,

(eq 2-9)

N

P

N

P

(A1 (I1)

where N is number of anodes required, I is total

2

0.00261

14

0.00168

protection current in milliamperes, A1 is anode sur-

3

0.00289

16

0.00155

4

0.00283

18

0.00145

face area in square feet per anode, and I1 is recom-

5

0.00268

20

0.00135

mended maximum current density output in milli-

6

0.00252

22

0.00128

amperes.

7

0.00237

24

0.00121

(5) Calculate number of anodes needed to

8

0.00224

26

0.00114

meet design life requirement. Equation 2-10 is used

9

0.00212

28

0.00109

to find the number of anodes:

10

0.00201

30

0.00104

12

0.00182

(L) (I)

N'

,

(eq 2-10)

(1000) (W).

Reproduced from W.T. Bryan, Designing Impressed Current

Cathodic Protection Systems With Durco Anodes, The Duriron

where N is number of anodes, L is life in years, and

Company, 1970. Used with permission.

W is weight of one anode in pounds.

(7) Select number of anodes to be used. The

(6) Calculate number of anodes needed to

highest number calculated by equation 2-9,2-10, or

meet maximum anode groundbed resistance re-

2-11 will be the number of anodes used.

quirements. Equation 2-11 is used to calculate the

(8) Select area for placement of anode bed.

number of anodes required:

The area with the lowest soil resistivity will be

DK

DP

chosen to minimize anode-to-electrolyte resistance.

Ra '

'

,

(eq 2-11)

(9) Determine total circuit resistance. The

NL

S

total circuit resistance will be used to calculate the

rectifier size needed.

(a) Calculate

anode

groundbed

tivity in ohm-centimeters, K is the anode shape

resistance. Use equation 2-11.

factor from table 2-5, N is the number of anodes, L

(b) Calculate groundbed header cable

is length of the anode backfill column in feet, P is

resistance. The cable is typically supplied with a

the paralleling factor from table 2-6, and S is the

specified resistance in ohms per 100 feet. The wire

center-to-center spacing between anode backfill

resistance then is calculated from equation 2-12:

columns in feet.

2-6

Previous Page

Previous Page