TM 5-811-7

will not fit into most rectifier cases. In addition, the rheostat consumes large amounts of power. This power

generates heat that can damage components inside the rectifier case unless good ventilation is provided. The

problems found with using a large rheostat can be overcome by using a separate rectifier for the riser anodes.

Although initial cost may be slightly high, power savings will be substantial and heat damage will be avoided.

(22) Size the rectifier for the riser.

(a) Requirements--d.c. output = 3.62 amperes, anode circuit resistance = 2.68 ohms, d.c. voltage

required = IR = 3.62 x 2.68 = 9.70 volts.

(b) Rectifier rating--standard ratings for a rectifier in this size class is 18 volts, 4 amperes.

(23) Find the rectifier d.c. rating for the bowl. Voltage output has been determined to be 80 volts.

Current rating is 15.2 amperes. The commercially available rectifier that nearest meets the above requirements

is 80 volts, 16 amperes.

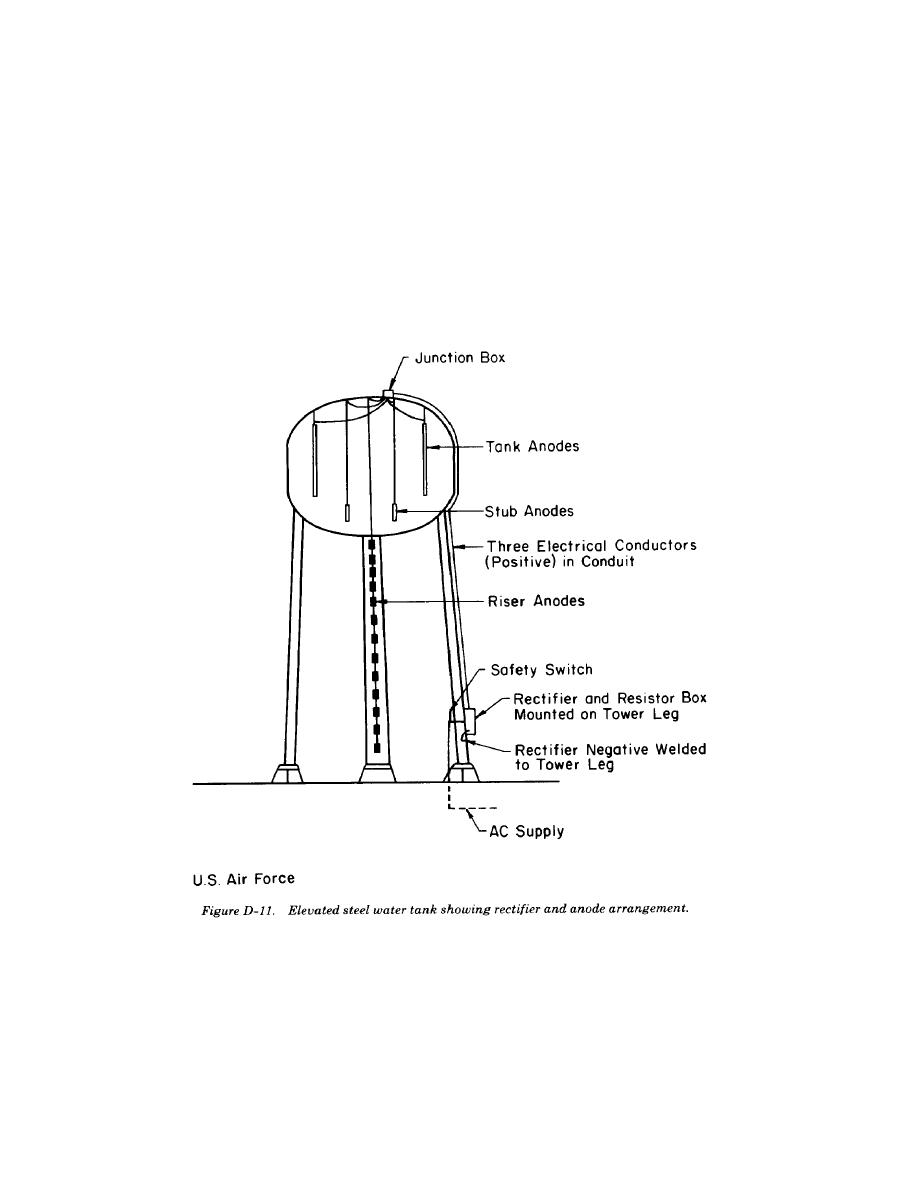

(24) Determine wire sizes and types. All positive feeder and suspension cables (rectifier to anodes)

must be No.2 AWG HMWPE insulated copper cable. To avoid complication, the negative rectifier cable

(rectifier to structure) must be the same size and type (fig D-11).

(25) Discussion of design.

(a) The design points out the drawbacks of controlling corrosion through cathodic protection

without the aid of a protective coating. For example, when the inside of a tank is coated, the current

requirement is reduced 60 to 80 percent. On large tanks without coating, larger and more costly anodes, wire,

and rectifier units must be used. In addition, the uncoated tank consumes far more power. These costs usually

exceed the cost of a quality coating system over a 10-year period. Corrosion above the water line of a water

storage tank is usually severe because condensation is corrosive. For this reason, protective coatings must

be used above the water line on both large and small water storage tanks to slow corrosion.

D-24

Previous Page

Previous Page