UFC 3-600-02

1 January 2001

2-2.4

Dry Pipe Automatic Sprinkler Systems. Technical guidance for these tasks

is contained in NFPA 25.

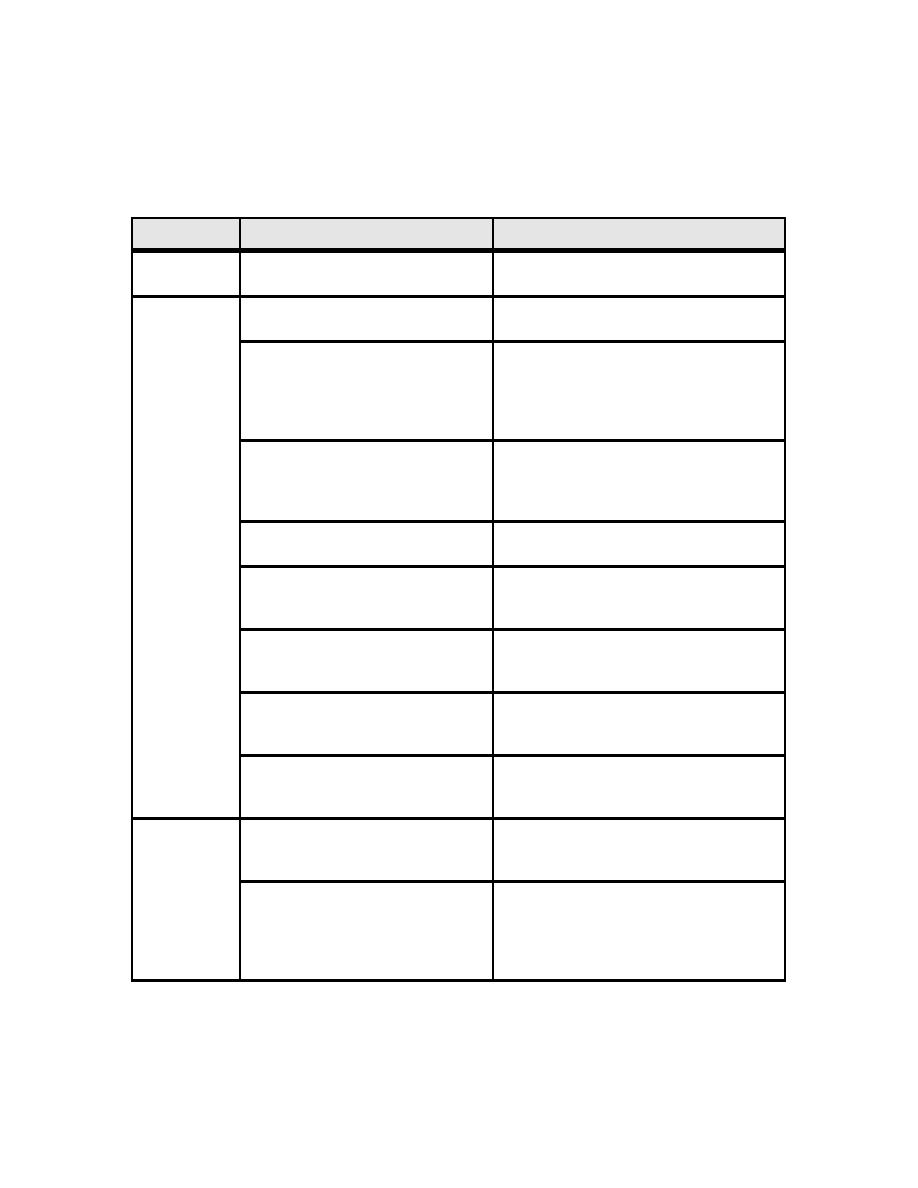

Table 2-3. Dry Pipe Automatic Sprinkler Systems ITM Tasks

Component

Tasks

Monthly

1. Control Valves (without lock 1. Verify valve position.

or supervision)

Annual

1. Control Valves (locked or

1. Verify valve position.

supervised)

2. Waterflow Alarm Devices

1. Operate to verify initiation and

receipt of alarm.

2. Verify alarm test valve align-

ment and tamper switch (if

supervised).

3. Dry Pipe Alarm Valve and Trim 1. Visually inspect exterior of valves,

gauges, trim alignment.

2. Verify valve pressure and legi-bility of

hydraulic nameplate.

4. Main Drain

1. Conduct main drain test to verify

supply (valve position).

5. Fire Department Connection

1. Verify accessibility and condition.

2. If caps removed or missing,

check for obstructions.

6. Dry Pipe Alarm Valve

1. Verify operability at beginning of

Enclosure Heating

heating season (for constant cold

areas annually).

7. Low Temperature Alarm

1. Verify initiation and receipt of

alarm at beginning of heating

season.

8. Low Point Drains

1. Drain all low points to remove

condensation prior to cold

season.

2 Years

1. Control Valves

1. Operate valve through entire travel to

verify function.

2. Lubricate valve stem.

2. Dry Pipe Alarm Valves

1. Trip valve to verify operability.

2. Inspect internal condition before

resetting and clean valve seat.

3. Check priming water level

(before and after trip test).

2-5

Previous Page

Previous Page