UFC 3-600-02

1 January 2001

2-2.3

Wet Pipe Automatic Sprinkler Systems. Technical guidance on the tasks in

Table 2-2 is contained in NFPA 25. Residential sprinklers are addressed in Chapter 3.

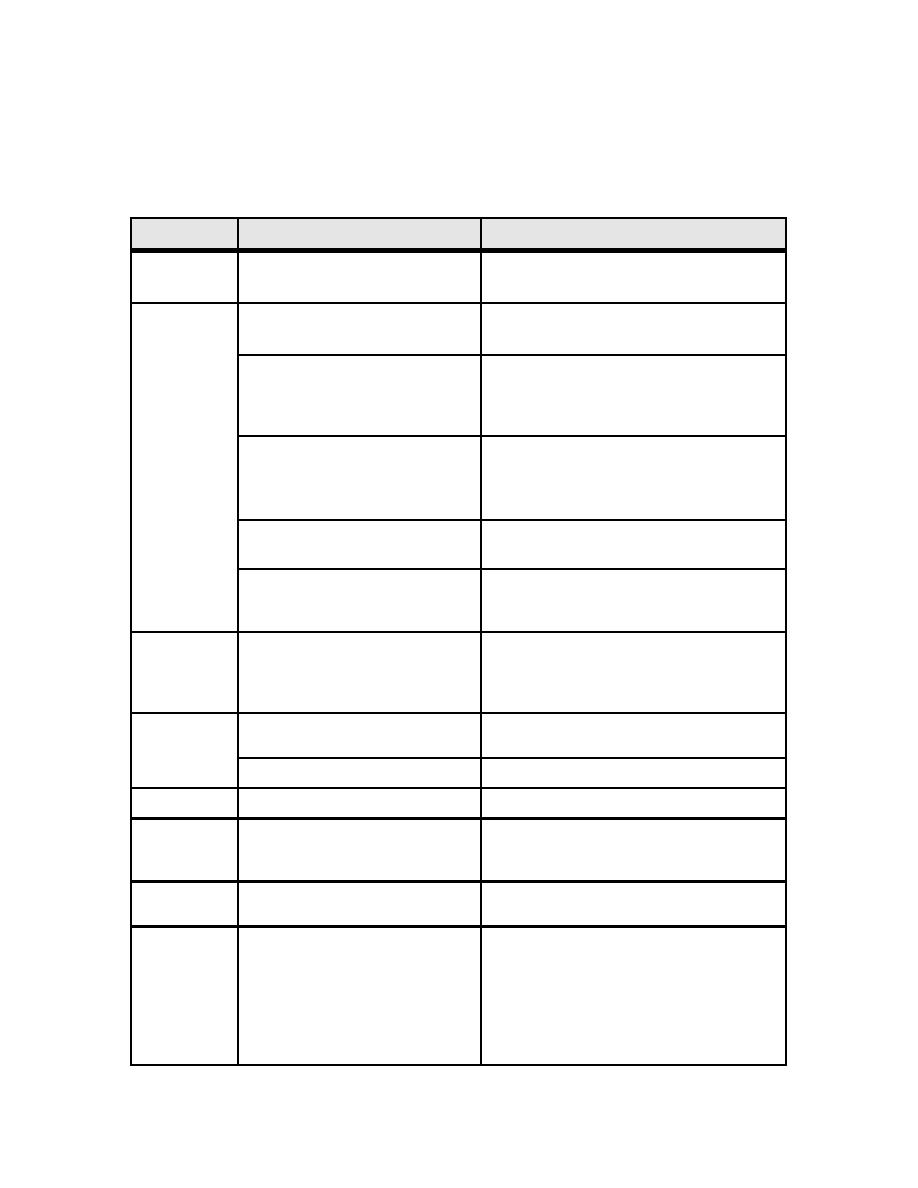

Table 2-2. Wet Pipe Sprinkler Systems ITM Tasks

Component

Tasks

Monthly

1. Control Valves (without

1. Verify valve position.

lock or supervision)

Annual

1. Control Valves (locked or

1. Verify valve position.

supervised)

1. Operate to verify initiation and

2. Waterflow Alarm Devices

receipt of alarm.

2. Verify alarm test valve alignment and

tamper switch (if supervised).

1. Visually check exterior of valves,

3. Alarm Valve and Trim

gauges, trim alignment.

2. Verify valve pressure and legibility

of hydraulic nameplate.

1. Conduct main drain test to verify

4. Main Drain

supply (valve position)

1. Verify accessibility and condition.

5. Fire Department

2. If caps removed or missing, check

Connection

for obstructions.

1. Operate valve through entire travel to

2 Years

1. Control Valves

verify function.

2. Lubricate valves and stems to ensure

operability.

1. Alarm Valve

1. Clean and inspect internally to

5 Years

verify condition.

2. Anti-freeze Loops

1. Confirm correct solution mixture

10 Years

1. Gauges

1. Recalibrate or replace gauges.

1. Fast Response Sprinklers

20 Years

1. Test sample heads to verify

and Extra High Temperature

response characteristics.

Heads

1. Replace or test sample heads to

50 Years

1. Standard Sprinkler Heads

verify response characteristics.

As Part of

Entire System

Visually check:

1. Pipe hangers.

Building

2. Heads for obstruction.

Inspection

3. Piping for leaks.

4. Riser condition.

5. Sprinkler spares.

6. Area susceptible to freezing.

2-4

Previous Page

Previous Page