TM 5-814-9

volumes, maximum wash water volume or

stormwater volume.

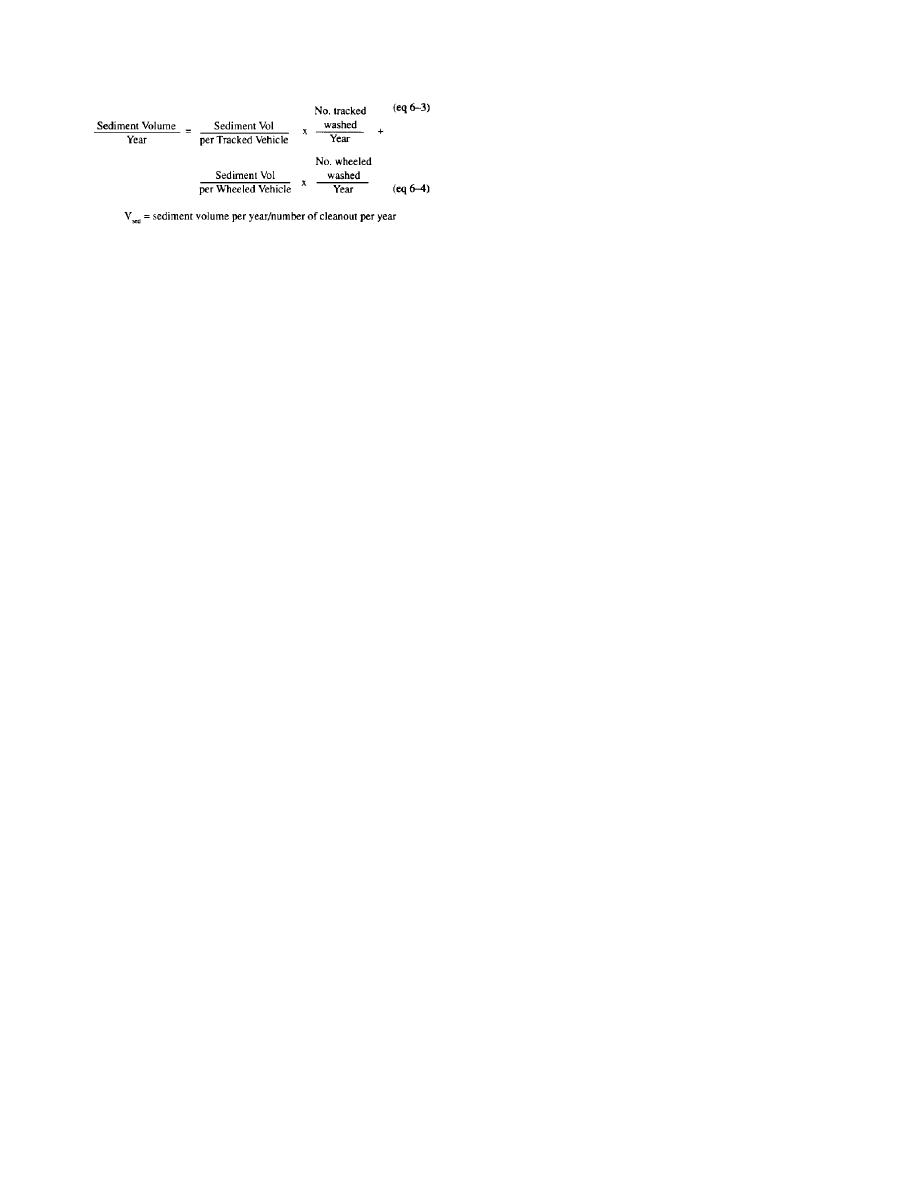

Volume = (Qover+U8xQ8) x TD + Vsed

(eq 6-6)

Dual-cell system. In a dual-cell system, each

(3)

cell must be sized to store the maximum vol-

ume expected at any given time. The volume

of each cell will depend on the larger of:

c.

Water volume. For a single-cell sediment basin, the

Case 1: Volume = 0.5 x Vsed + Qover x TD + V1

cell should be sized for a detention time of from 2 to

4 hours. For a dual-cell basin, each cell should be

Case 2: Volume = 0.5 x Vsed + 0.5 Q9Ts

sized to detain the wastewater for 2 to 4 hours with

6-15. Sediment basin influent structure

cells operating in parallel; or from 1 to 2 hours with

one cell in operation. Wastewater having a high

The influent line should empty into the deep end of each cell of

cohesive soil content will require settling times at

the basin, opposite a ramped entrance that provides access for

the upper limit of the range; settling times for

the cleaning equipment. A structural baffle or energy dissipator

noncohesive soils should be at the lower end of the

may need to be installed at the influent end to disperse the

range. One method of determining optimal deten-

wastewater and solids across the width and to help prevent

tion time (TD) and settling velocity is to perform

water and solids from short-circuiting to the effluent structure.

bench-scale settling tests for the soil conditions at

The inlet invert must be placed higher than the maximum water

each training site. Another method is to use Stoke's

level in the basin to prevent deposition of solids in the influent

Law in computing trap efficiency. The basin should

line or inlet structure. Motorized gates may be used in a two cell

have a total effective water depth of 5 to 8 feet (1.5

basin to make it convenient for the operator to switch the

to 2.5 meters).

influent flow from one cell to the other or to use both.

Sediment basin overflow rate. The basin

(1)

6-16. Sediment basin effluent structure

overflow rate is an estimate of the flow rate of

The effluent structure must be located opposite the influent end

wash water used during a wash period (Tw (eq

in order to maximize the detention time in the basin. Protective

6-5). It is determined by reducing the maxi-

baffles, fixed or removable, may be installed in front of the

mum flow rate by usage factors. This flow

effluent opening to prevent discharge of floating debris and oil.

rate is used when determining the detention

A section through the overflow trench for a basin without bath

time and sizing the cells for the sediment

is shown in figure 66. The effluent structure for a basin with

basin. The designer must use discretion as to

bath consists of adjustable, motorized gates used to regulate the

whether the trench flushers in the wash area

height of the water in the basin (fig 6-7). This arrangement

will be operable while the vehicles are being

allows the operator to alternate treatment from one cell to the

washed. The trench flushers in a bath will not

other or use both cells in parallel.

operate during washing. The designer also

must use engineering judgment as to what

6-17. Sediment basin construction

percentage of time the trench flushers (if any)

Sediment basins are constructed of concrete in order that a

in the vehicle preparation area will be

front-end loader can enter the basin at the ramp and remove the

operable while the vehicles are being washed.

sediment without damaging the liner. In addition, a concrete

basin prevents oil and other wastes from seeping out of the

Qover=U2Q2+U3Q3+U4Q4+U5Q5+U6Q6+U7Q7

(eq 6-5)

basin into the surrounding soils.

Single-cell system. In a single-cell system, the

(2)

6-18. Sediment basin drainage

cell should be designed to store the water for

a.

the designed detention time and should also

The sediment basin must be provided with a drain-

hold the sediment volume collected between

age system which (1) allows the captured sediment

cleanouts. Equation 66 gives the water and

to dewater for easier removal from the basin; (2)

sediment volumes needed for sizing a single

controls the discharge of large volumes after drain-

cell at a facility without a bath. If a bath is

ing the prewash bath facilities; (3) permits other

provided, the bath volume, V1, must be added

routine maintenance to the structure and/or equip-

to the equation. This equation calculates only

ment; and (4) permits preparation for winter shut-

water and sediment volumes; it does not in-

down.

clude the freeboard which must also be added.

b.

Also Q9, stormwater flow, would not be nor-

Drain down of the basins for cleaning is accom-

mally considered an additive flow. The basin

plished through a drain line with a manually oper-

should be sized to handle the greater of two

ated valve as depicted in fig 6-8. Drain down of

6-8

Previous Page

Previous Page