TM 5-814-9

6.21 Waste oil storage

must be strategically located, easily accessible for servicing and

durable. Daily inspection of the oil skimmer unit is required to

Waste oil storage tanks are designed, constructed and installed

insure continuous, trouble-free operation.

in accordance with current U.S. Environmental Protection

Agency, State, or Local regulations for above ground or

6-23. Other considerations

underground storage tanks. Storage tanks should be 500- to

2000-gallon (1893- to 7570-liter) capacity, depending on the

Sediment basins should have pipe rail or fencing mounted on

estimated amount of oil recovery and frequency of cleanout.

the wall in accordance with OSHA requirements for safety

Positive spill containment should be provided at the cleanout

considerations; or the grade surrounding basins located lower

port and directed back to the sediment basin.

than top of wall to provide a safety barrier. Hydrostatic pressure

relief should be provided where generally high water tables

6-22. Maintenance

exist and basins should be designed to prevent flotation when

empty. Access ramps should be serrated for vehicle traction.

Routine maintenance of the sediment basin and appurtenances

Inlet and outlet ends should be readily accessible to operators,

will be minimal. Sediment should be removed from each cell at

through an access road around the basins. Lighting should be

least once per year. The waste oil storage tank should be

provided at the inlet structure and at the outlet structure.

emptied before its capacity has been reached. Provide appro-

priate site gauges and/or high level alarms. Oil skimmer devices

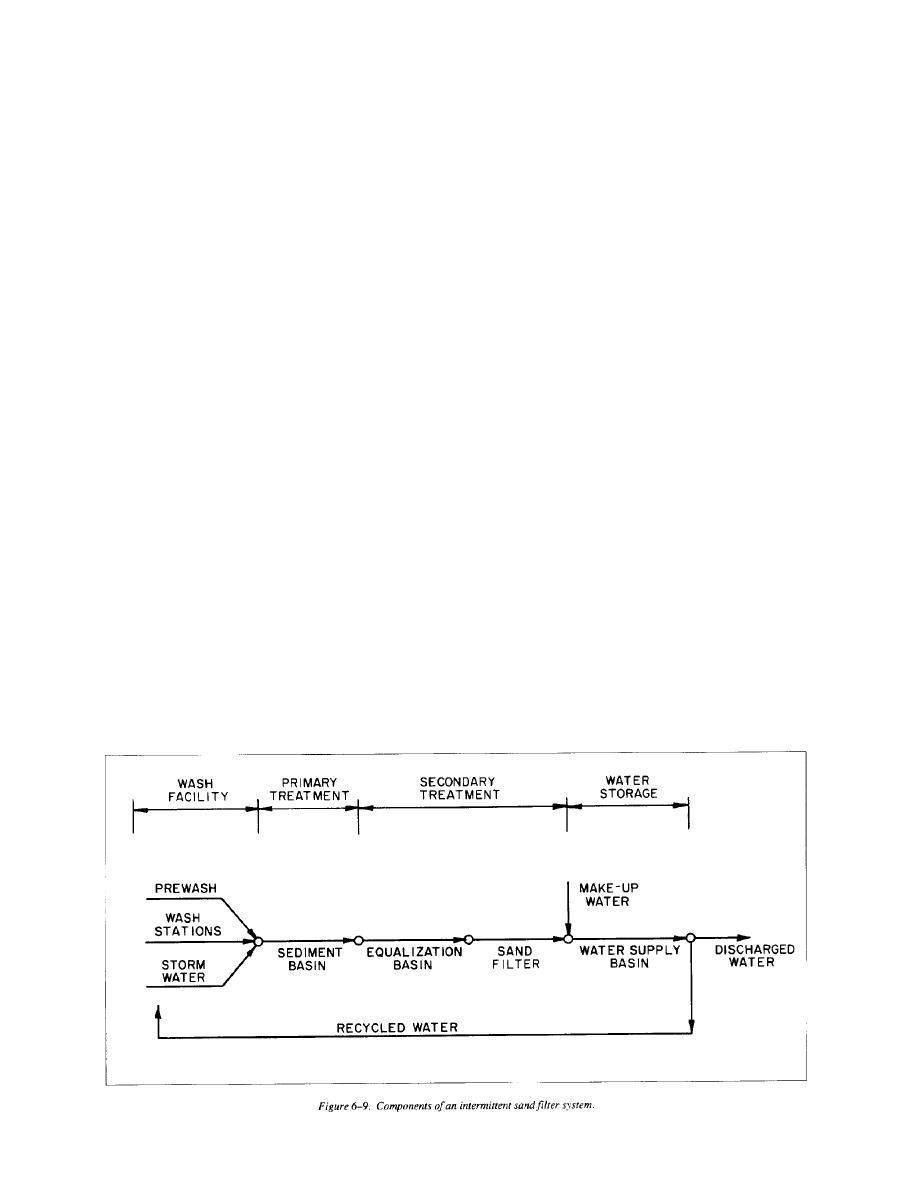

Section IV. SECONDARY TREATMENT

6-24. Onsite secondary treatment

and series lagoons. Intermittent sand filter systems are the

preferred secondary treatment method for CVWFs. Where

At installations where an adequate, dependable, low-cost wash

existing ponds, lagoons, or basins are available and

water source cannot be found, and favorable site and weather

environmentally suitable for use, a lagoon system should be

conditions exist, a recycle water system should be used. The

considered. The most environmentally acceptable, cost-effective

water source must adequately supply clean water on demand

system should be used.

during the peak wash periods. The quality of effluent from a

sediment basin usually is not adequate for discharge to a sewage

6-25. Objective

treatment plant, even if treating non-cohesive soils and

therefore, cannot be used as recycled water. For recycling,

Secondary treatment removes suspended matter, microorgan-

secondary treatment is required. If an adequate water supply

isms, impurities, and minor residual oils from the product water.

source is available and recycling would not be economical, the

These materials are carryovers from the primary treatment

wastewater may be discharged to an existing sewage treatment

process and consist mostly of colloidal materials such as clays

plant for further treatment. In this case, onsite sediment basins

and fines that have not been removed during sedimentation. The

followed by an equalization basin would still need to be

removal of these suspended solids is essential to produce a

provided. Two altemative onsite secondary treatment systems

relatively clean, clear, acceptable product for recycling as wash

are available for treating waste washwater to a quality suitable

water.

for reuse in vehicle washing, namely, intermittent sand filtration

6-12

Previous Page

Previous Page