I

Page 33

DG 1110-3-124

August 1976

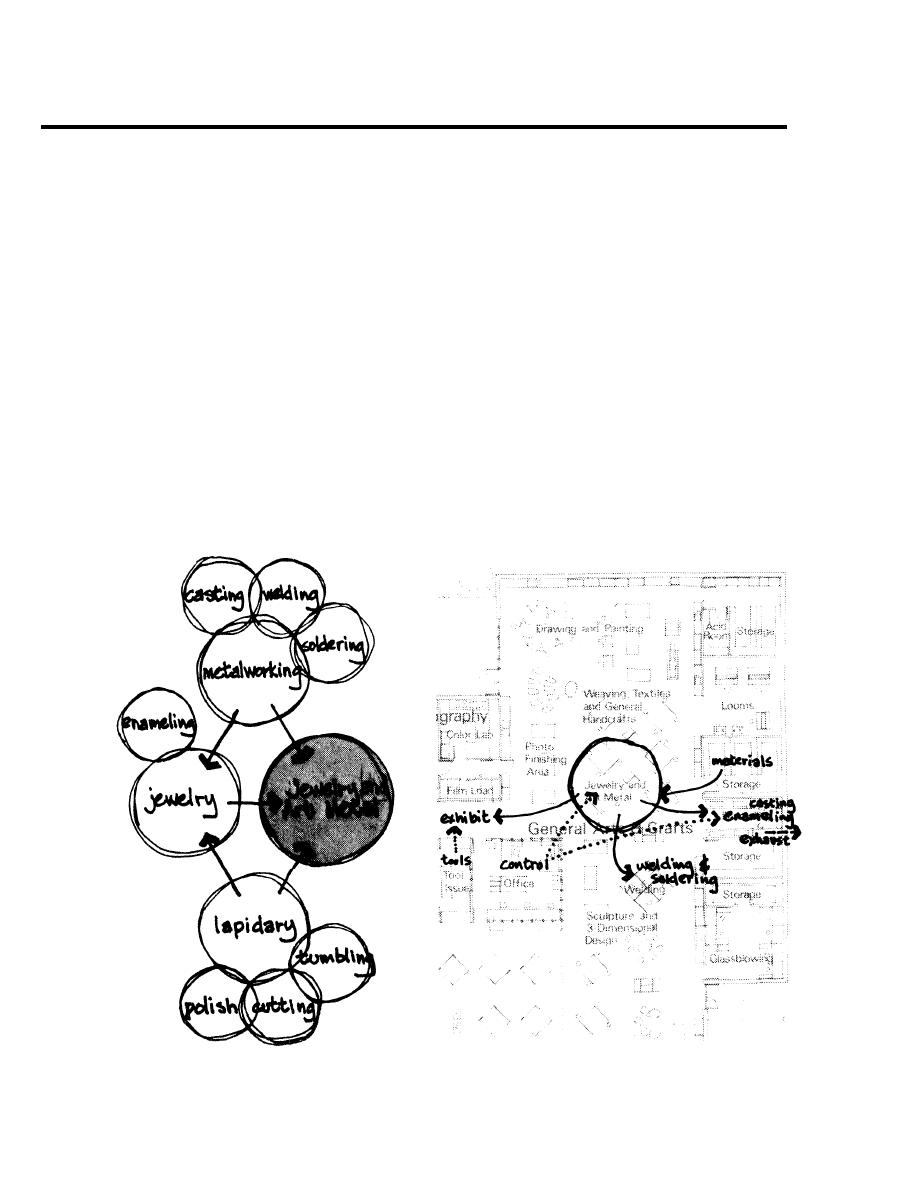

g.

TECHNOLOGICAL

REQUIREMENTS

f. FURNISHINGS EQUIPMENT

Grinding arbors and grinding/polishing units require pres-

Much of the jewelry work can be done at standard work

sure water connections which is preferable to a siphon

counters with accessory V-blocks, anvils, gas fixtures and

water system. A sediment sink is necessary for washing

vises attached. Alternatively, two to four jeweler's work-

stones and castings, mixing casting investment and clean-

benches can be provided in the general work space. At

ing metals. Toxic chemicals must be disposed through

least one asbestos-covered work top is needed, Hot metal

acid-resistant sinks and piping. Exhausts are required for

casting requires furnaces which should be vented. Slab

hot metal casting equipment, ovens, torches, and spray

saws and flat laps are floor mounted items. Combination

booths. Some electric kilns and lapidary equipment may

lapidary units can perform several operations but limit the

require 220 volts but most jewelry equipment requires

number of active participants. Therefore in a large shop,

110 volts. Supplies of oxygen, gas and compressed air are

separate lapidary units for cutting, grinding, polishing and

required. In addition to normal lighting levels, concen-

buffing are preferable. Water connections are required for

trated local lighting is required for delicate tasks.

some grinders. Buffing machines, drill presses, trim saws,

centrifugal and vacuum casting machines, faceting

machine, grinding arbors, burn out kilns, sanders and gem

tumblers can all be bench mounted. Lapidary equipment

should be so placed as to facilitate the progression of

operations from dabbing, trimming and grinding through

polishing and faceting.

Activities

Previous Page

Previous Page