MIL-HDBK-1005/9A

Table 4

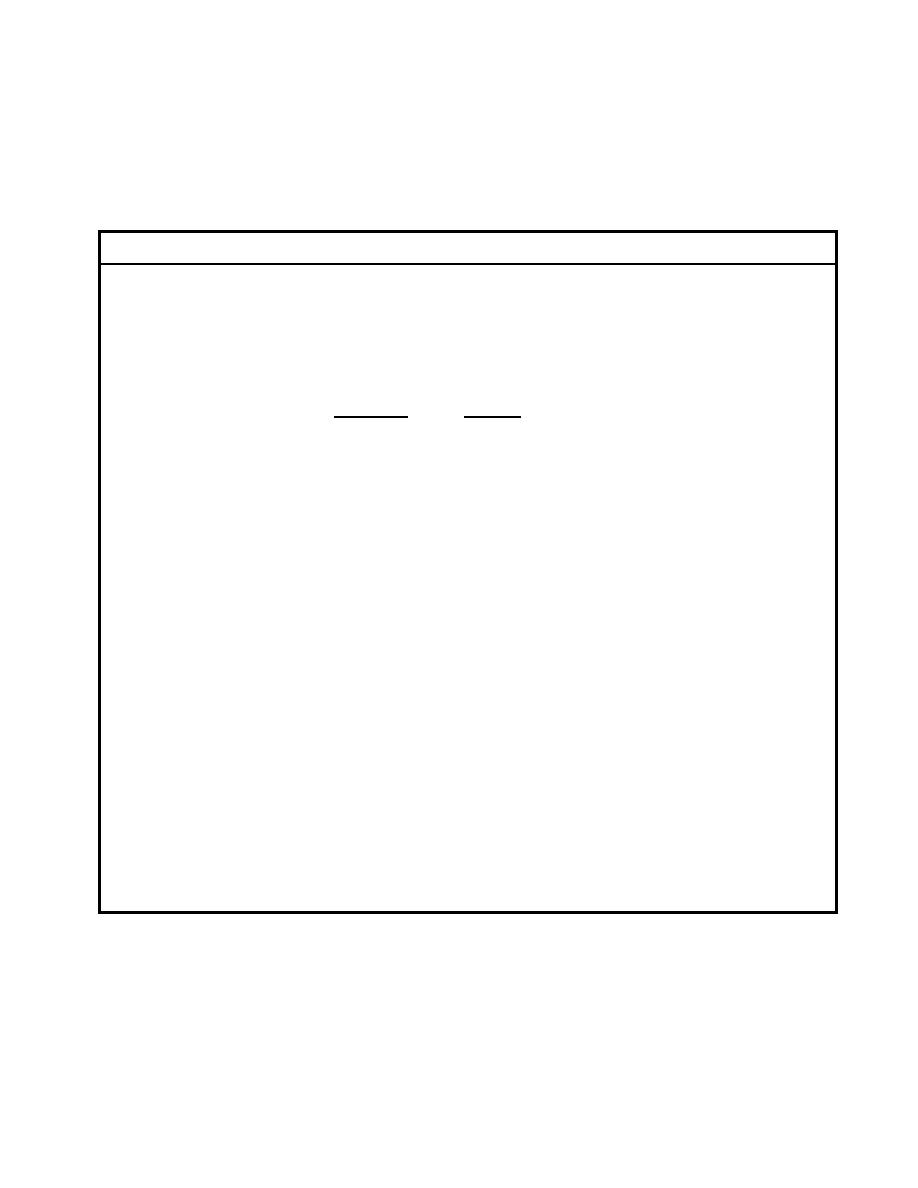

Sewer Structures

Structure

Type

Where to Use

Details and Special

Considerations

Manhole

Regular

Terminally on all lines; at

Refer to NFGS-02530.

all junctions and changes

Lower invert through manhole a

of direction; at changes in

distance equal to expected loss

invert elevation or slope.

of head in manhole, plus 0.8

Otherwise, according to

times any change in sewer size.

spacing shown below:

For junction manholes, check

Pipe Size

Max.

which upstream invert is

spacing

critical in determining outlet

(in.(mm))

(ft(m))

invert. Raise top of manhole

≤18(450)

above possible flooding level.

400(120)

18-48(450-1200) 500(150)

≥48(1200)

600(180)

Drop

When difference between

Refer to NFGS-02530

inlet and outlet inverts

exceeds 2 ft (0.6 m)

For difference less than 2 ft

(0.6 m), increase upstream

sewer slope to eliminate drop.

Siphons

Inverted

For carrying sewers under

Maintain velocity of 3 fps (0.9

obstructions or waterways.

m/s). Use not less than two

barrels with minimum pipe size

of 6 in. (150 mm). Provide for

convenient flushing and

maintenance.

Use WPCF MOP FD-5 for hydraulic

design.

Interceptor

--

Where discharge of existing

Take special care against

Sewers

sewers must be brought to a

infiltration due to depth or

new concentration point.

proximity of surface water.

Traps and

Grease and

On outlets from subsistence

Displacement velocity 0.05 fps

Inceptors

Oil

buildings, garages,

(0.015 m/s). Grease removal--in

mechanical shop, wash pits,

absence of other data use 300

and other points where

to 400 mg/L. Provide for

grease or oil can enter

storage of one week's grease

system.

production (one day if

continuous removal is

provided). Length = twice depth

28

Previous Page

Previous Page