MIL-HDBK-1005/9A

Table 9

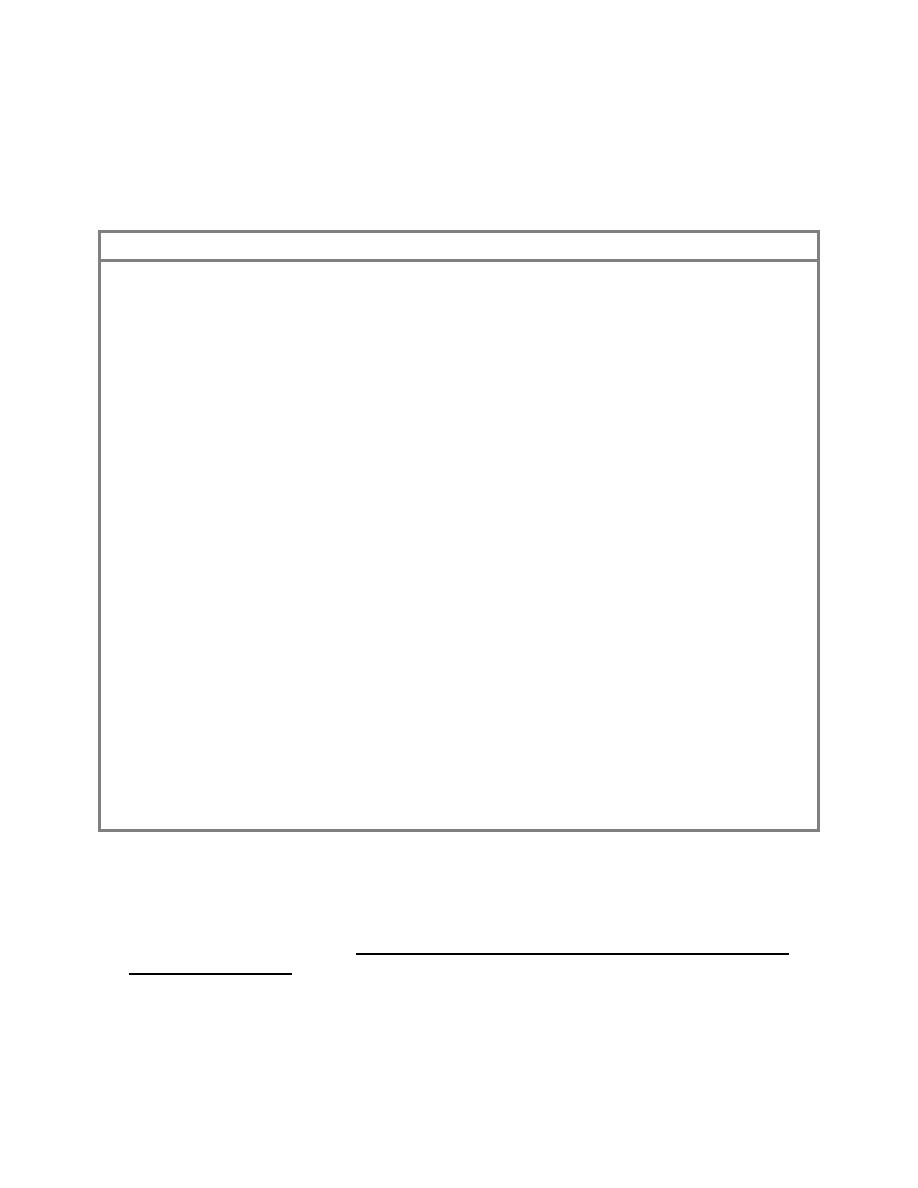

Granular Carbon Adsorption Treatment Applications

Type of Carbon Adsorption Treatment

Design Factors

Secondary

Advanced

Pretreatment requirements

Chemical clarification using

Any type of standard primary

primary coagulants to achieve

with secondary processes.

maximum suspended solids

removals. If the suspended

solids concentration is higher

than 50 to 65 mg/L,

prefiltration should be

considered.

Activated carbon facilities:

Activated carbon particle size

8 x 30 mesh

8 x 30 or 12 x

40 mesh

2 to 6 gpm/ft2 (81.5 to 244.5

3 to 8 gpm/ft2

Hydraulic loading

(122.2 to 326.0

L/min-m2) with one unit being

L/min-m2) with

one unit being

backwashed and one unit out of

backwashed and

one unit out of

service.

service.

Contact time

30 to 50 min

15 to 40 min

20 to 30 gpm/ft2 (814.9 to

10 to 15 gpm/ft2

Backwash rate

(407.5 to 611.2 L/min-m2)

1222.4 L/min-m2)

Surface wash

Recommended

Recommended

Recommended bed expansion

40%

40%

Carbon bed depth

15 to 30 ft (4.6 to 9.2 m)

10 to 20 ft (3.05 to 6.10 m)

Flow configuration

Fixed beds in series or

Fixed beds in series or

parallel, moving beds, and

parallel, moving beds, and

expanded upflow beds.

expanded upflow beds.

Carbon requirements

Determine by experiment (range

Determine by experiment (range

= 300 to 1,000 lb/Mgd [3106 to

= 250 to 500 lb/Mgd

10,354 kg/m3-s]

[2588 to 5177 kg/m3-s])

Carbon regeneration facilities1

Multiple hearth2

Multiple hearth2

Regeneration type

Percent of time required on

40 to 60%

40 to 60%

stream

Additional makeup carbon per

10%

10%

pound carbon regenerated

1650 to 1800F (899 to 982C)

1650 to 1800F (899 to 982C)

Furnace operating temperature

Flue gas quench and scrubber

Flue gas quench and scrubber

equipment

system

system

Activate carbon performance

Determine by bench or pilot

Determine by bench or pilot

evaluation3

scale study

scale study

1

Use offsite regeneration unless economic advantages

significantly favor onsite facilities.

2

For a carbon regeneration requirement of less than 8,000 lb/d,

consider a rotary kiln type furnace.

3

For description of adsorption isotherm test and column test

procedures, refer to Process Design Techniques for Industrial

Waste Treatment, by Adams and Eckenfelder.

60

Previous Page

Previous Page