MIL-HDBK-1005/9A

Table 14

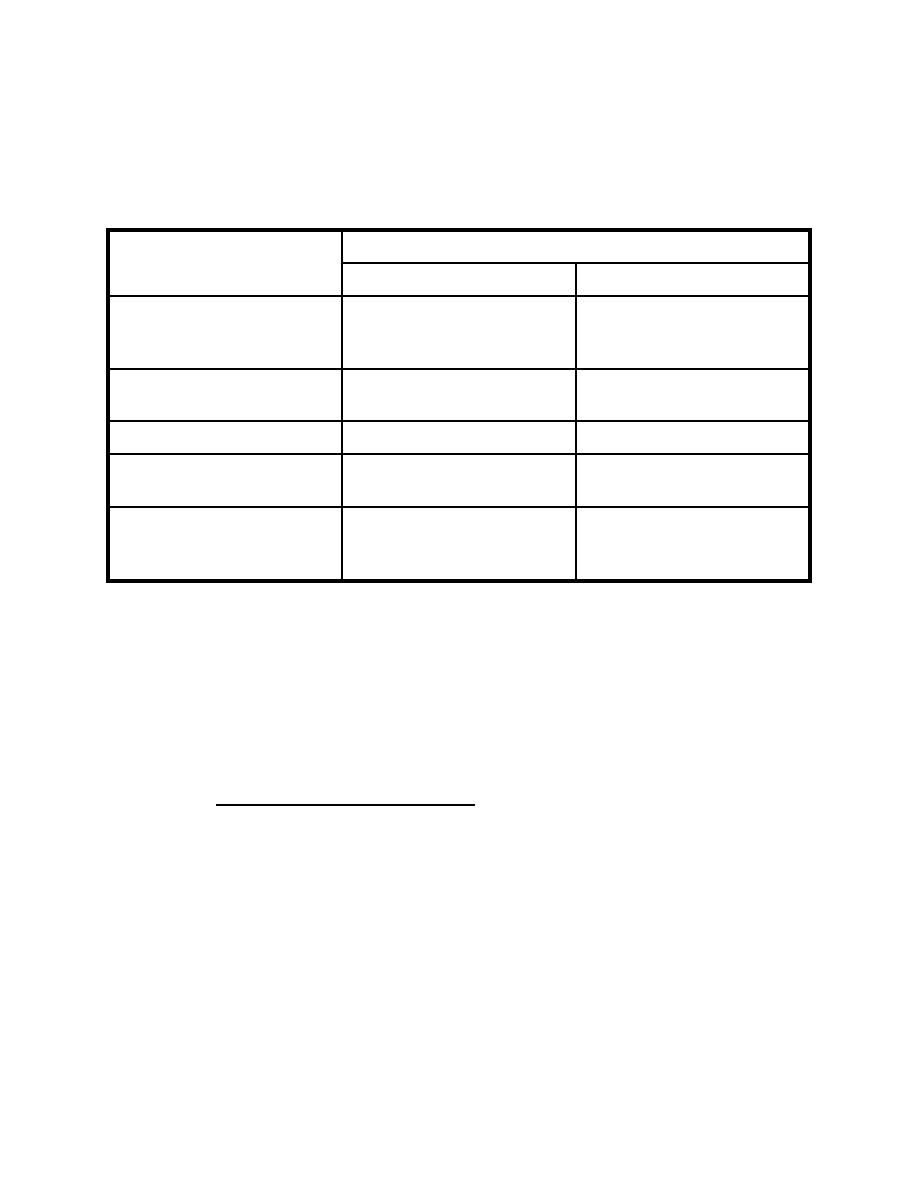

API Separator Design Criteria

Design Parameter

Design Flow Rate

<185 gpm (11.7 L/s)

>185 gpm (11.7 L/s)

1

2

Maximum Surface

1,000 to 2,000

1,000 (11.3)

Loading, gpd/ft2

(11.3 to 22.6)

(L/s-m2)

Length:Width

4:1

4:1

(minimum)

Depth:Width

1:1 (maximum)

0.3:1 to 0.5:1

3

Maximum Depth, ft

3 (0.9)

5 (1.5)

(m)

Maximum Horizontal

2 (0.6)

2 (.06)

Velocity, fpm

(m/min)

1

Based on maximum 24-hour flow with one tank out of service.

2

Use lower value if separator is only form of treatment. Use

higher value of separator is a pretreatment or intermediate

component of a multi-unit treatment system or if effluent

quality complies with POTW discharge regulations.

3

Increase depth to provide oil and sludge storage volume as

required.

3.10.4.1 Parallel Plate Separator. Use the wastewater

characteristics developed in accordance with Section 3. Refer

to paragraphs 3.7.2 and 2.7.4 to design separator for removal of

free oil and, if required, suspended solids. Locate units above

ground or partially buried. Protect buried units against

flooding from surface runoff by locating a minimum of 8 inches

(203 mm) above grade. Consider the following during design:

a) Tanks should be fabricated from carbon steel and

coated inside and outside with coal tar epoxy. Preferred

construction materials for plate packs are a frame of Type 304

stainless steel with individual plates of fiberglass. Refer to

142

Previous Page

Previous Page