TM 5-628/AFR 91-44

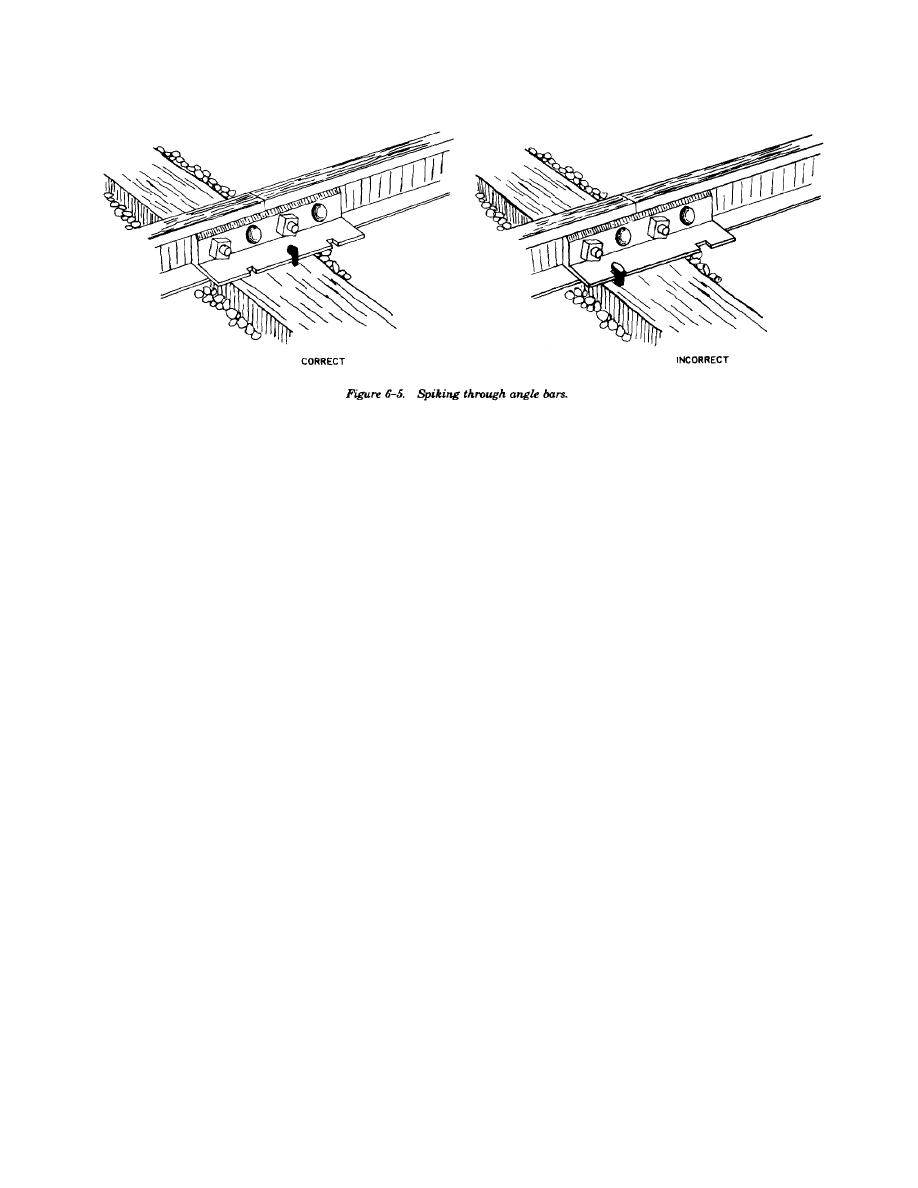

(4) Correction on incorrect spiking patterns.

including the bolt holes. Joint bars not meeting

An incorrect spiking pattern by itself is not a cause

these requirements shall be replaced.

b. Compromise joints. Rails of different size or

for removing and redriving spikes. However, an

incorrect spiking pattern shall be corrected when

section shall be joined with proper factory designed

other maintenance requires the spikes to be

and constructed compromise bars, taper rails, or

removed. Old spike holes shall be plugged to pre-

offset welds.

c. Cracked or broken joint bars. Cracked or

vent accelerated tie deterioration.

d. Missing and loose spikes. Missing spikes

broken joint bars shall be replaced.

shall be replaced. Old spike holes shall be plugged

(1) If one joint bar at a rail joint is cracked

with a treated tie plug prior to replacing the spikes.

or broken between the center holes, operations

Loose spikes shall be removed, the holes plugged,

over that location shall not exceed 10 mph.

and the spikes redriven.

(2) If both joint bars at a rail joint are

e. Spikes beneath rail base. Where the head of

cracked between the center holes, operations over

a spike has become lodged beneath the base of a

that location shall not exceed 5 mph.

rail, the spike shall be removed and properly

(3) Operations shall not be permitted over

redriven. A spike lodged beneath the rail base is an

any location where both joint bars are broken, or

undesirable condition that can lead to a broken rail

where worn or loose joint bars allow vertical move-

base.

ment of either rail with respect to the other.

d. Bolts. Each joint shall be bolted with at least

two bolts in each rail.

6-4. Joints.

(1) All bolts shall be of proper size and

a. Joint bars. Rails shall be joined with proper

tightly in place. A bolt is not considered tight

factory designed and constructed joint bars. Joint

unless the spring washer is compressed closed and

bars may not be altered with a flame in any manner,

is flat against the joint bar, as shown in figure 6-6.

6-3

Previous Page

Previous Page