TM 5-628/AFR 91-44

f. Running surface damage. Rail running sur-

c. Torch cut. Rail shall not be flame cut in any

face damage, such as deep engine burns, dents,

manner. This includes cropping of the rail end,

etc., is measured at the midpoint of an 18-inch

burning bolt holes, and trimming mismatched ends.

straightedge laid on the railhead over the defect.

Rail shall be cut using a rail saw or other

Table 7-1 presents limits and remedial actions for

appropriate cutting tool.

d. Short rail. Rail less than 13 feet in length

rail surface damage.

shall not be installed in track.

7-2. Rail maintenance.

7-3. Lightweight rail.

a. Rail. New rail used in the maintenance of

Army and Air Force track shall meet the require-

Lightweight rail is defined as rail weighing less than

ments specified in the AREA Manual For Railway

90 pounds/yard. Research has shown that light-

Engineering, chapter 4.

weight rail may not be suitable for use in track

b. Internal defect inspection. A "continuous

which is subjected to heavy wheel loads.

a. Rail weights of 70 pounds/yard or less

search" internal rail defect inspection shall be per-

formed at least once every 3 to 6 years on Catego-

should be replaced if that rail is to experience car

ries A and B track. This internal rail defect in-

loads of more than 50 tons (25,000 pounds axle

spection should be conducted using ultrasonic in-

loads).

b. Rail weighing 75 to 85 pounds/yard may be

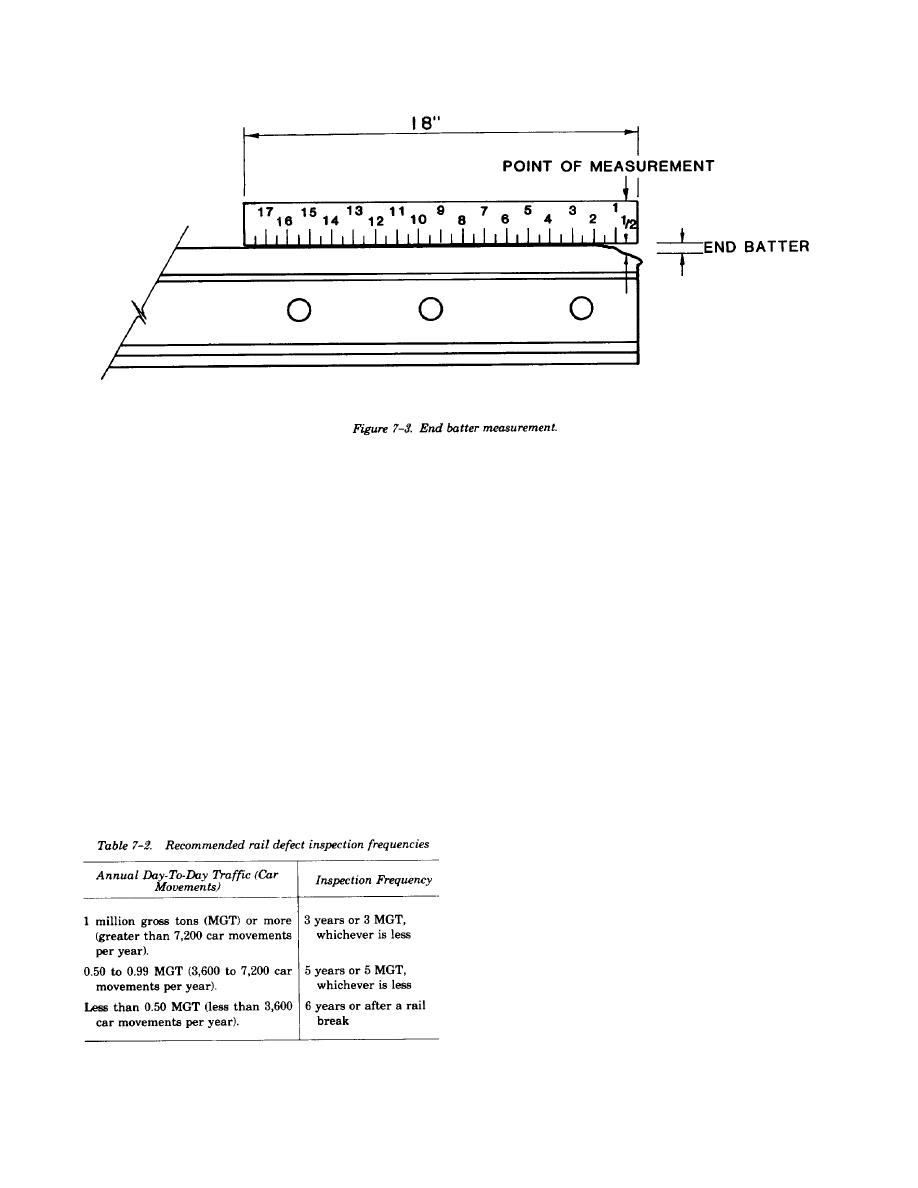

spection techniques. Table 7-2 presents the recom-

mended frequency for rail defect inspections.

adequate depending upon support conditions. A

structural evaluation and stress analysis is necessary

to determine the adequacy of these rail weights.

Rail not adequate to support the desired wheel

loads should be replaced.

c. The existence of lightweight rail in

Categories A and B track should be considered

when planning major repair and/or rehabilitation

projects.

7-4

Previous Page

Previous Page