TM 5-628/AFR 91-44

(4) Where washers or similar spacers are

outside of the stock rail on both sides of the turn-

between the clip and switch point, operations

out.

through the turnout shall not exceed 10 mph.

(2) It is recommended that rail braces be in-

h. Connecting rod bolts, switch rod bolts, and

stalled on each tie from the point of switch to

clip bolts. Connecting rod and switch rod bolts

within two ties of the switch heel.

shall be installed with the nut on top and cotter

(3) If there are less than four rail braces

keys in place. Clip bolts shall have cotter keys. All

fully secured to the tie and tight against the outside

bolts shall be kept tight.

of each stock rail, operations through the turnout

i. Switch heel (bolts, fillers, and joint bars).

shall not exceed 5 mph.

k. Debris in flangeways. Flangeways shall be

The heel of the switch shall be secure and the

supporting switch ties solidly tamped. The inside

kept clear of debris. Any obstructions, including ice

joint bar (nearest and track center) should be a bent

and packed snow, shall be removed.

bar per AREA design. If any heel bolts are loose or

missing, or the heel is otherwise not fully secure,

8-4. Frogs.

operations through the turnout shall not exceed 5

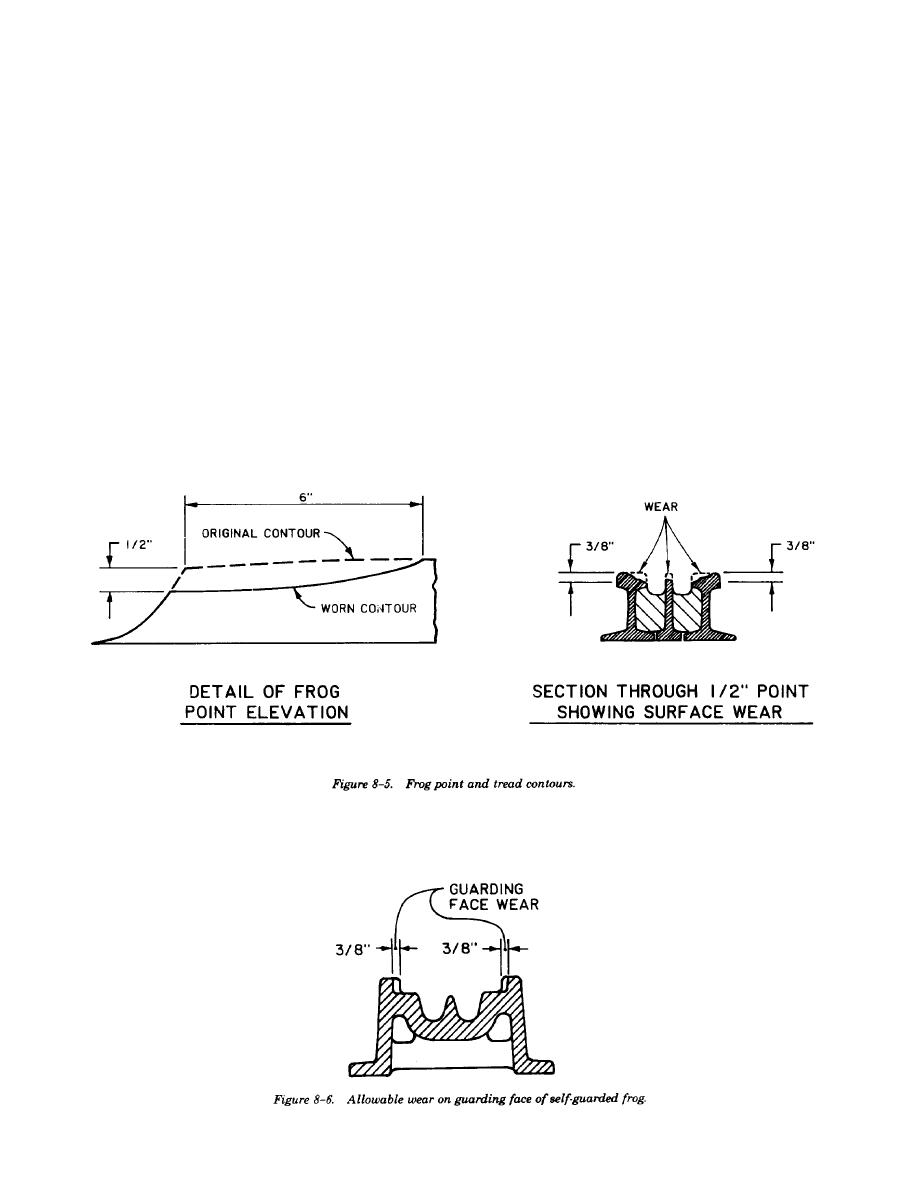

a. Frog point. A frog shall be restored or re-

mph.

placed if the point is chipped, broken, or worn

j. Rail braces.

more than (0.50) inch below the original top sur-

(1) Rail braces are essential to provide

face and 6 inches back from the original point lo-

proper lateral support to the stock rails. Rail braces

cation. (See fig 8-5)

shall be fully secured to the tie and tight against the

b. Frog surface. A frog shall be restored or re-

c. Guarding face of self guard ed frogs. The

placed if the tread surface is worn more than d

raised guarding face on a self-guarded frog shall

not be worn more than d (0.375) inch. (See fig 8-6)

(0.375) inch below its original contour. (See fig 8-5)

8-4

Previous Page

Previous Page