TM 5-810-15

fired units may be specified for boilers with

oil characteristics are similar to natural gas. Even

capacities of 100,000 pph and above. Field erected

though oil contains little ash, other constituents

atmospheric circulating fluidized bed boilers

such as sulfur, sodium and vanadium present

(ACFB) are 80,000 pph or larger. Gas and oil fired

problems. These concerns include emission of

boilers and field erected for capacities of 200,000

pollutants, external deposits and corrosion.

d. Fuel oil analysis. Historically petroleum re-

pph or larger. Field erected units are the only

boilers available for any of these technologies

fineries have produced five different grades of fuel

above 200,000 pph.

oil. Fuel oils are graded according to gravity and

viscosity as defined by ASTM standard specifica-

tions with No. 1 being the lightest and No. 6 being

3-4. Available fuels.

the heaviest. Table 3-2 lists typical analyses of the

a. Natural gas. Natural gas is the cleanest

various grades.

burning of the widely used commercially available

e. Coal types. For the purpose of boiler design,

fuels. It contains virtually no ash which reduces

domestic U.S. coals are divided into four basic

design, building and operating costs. This also

classifications: lignite, subbituminous, bituminous,

eliminates the need for particulate collection

and anthracite. Anthracite, however, requires spe-

equipment such as baghouses or electrostatic pre-

cial furnace and burner designs due to its low

cipitators. Thorough mixing with combustion air

volatile content and is not normally used in the U.S.

allows low excess air firing. The high hydrogen

for boiler fuel. Note the following illustrations,

content of natural gas compared to the oil or coal

figures 3-1 and 3-2. In general, these coal

causes more water vapor to be formed in the flue

classifications refer to the ratio of fixed carbon to

gas. This water takes heat away from the combus-

volatile matter and moisture contained in the coal,

tion process, making less heat available for steam

which increases with the action of pressure, heat,

generation which lowers the boiler efficiency.

and other agents over time as coal matures. The

b. Natural gas analysis. Two types of analyses of

changes in this ratio over the stages of coal

natural gas are commonly used. Proximate analysis

information are illustrated in figure 3-3. Volatile

provides the percentage content by volume of

matter consists of hydrocarbons and other com-

methane, ethane, carbon dioxide and nitrogen.

pounds which are released in gaseous form when

Ultimate analysis provides the percentage content

coal is heated. The amount present in a particular

coal is related to the coal*s heating value and the

oxygen. Table 3-1 gives natural gas analyses from

rate at which it burns. The volatile matter to fixed

selected United States fields.

carbon ratio greatly affects boiler design, since the

c. Fuel oil. Compared to coal fuel oils are rela-

furnace dimensions must allow the correct retention

tively easy to handle and burn. Ash disposal and

time to properly burn the fuel.

emissions are negligible. When properly atomized

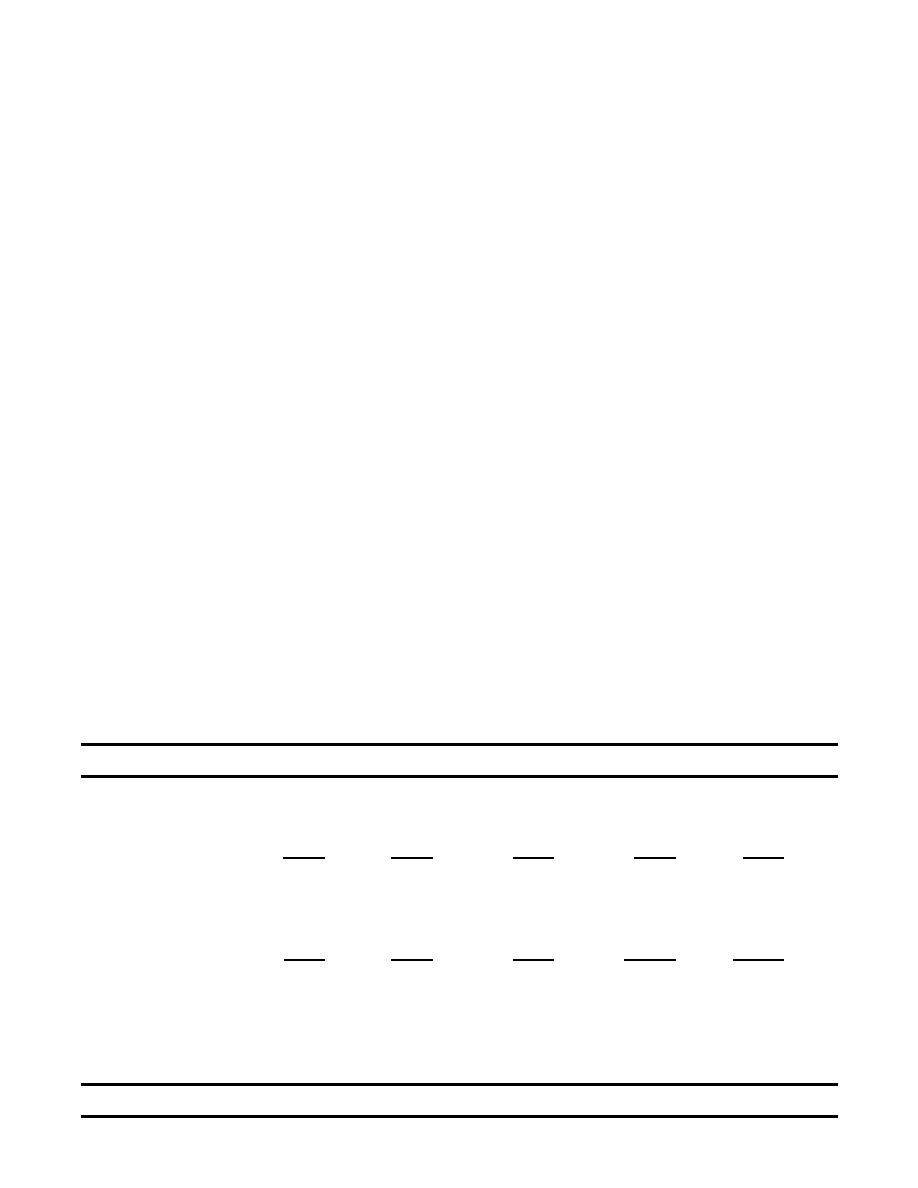

Table 3-1. Analyses of Natural Gas from Selected United States Fields.

Pittsburg

So. Cal.

Birmingham

Kansas City

Los Angeles

Proximate, % by Volume

Methane CH4

83.40

84.00

90.00

84.10

77.50

Ethane C2 H6

15.80

14.80

5.00

6.70

16.00

Carbon D.C02

--

0.70

0.80

6.50

0.50

5.00

8.40

--

Nitrogen N2

0.80

Total

100.00

100.00

100.00

100.00

100.00

Ultimate % by Weight

Hydrogen H2

25.53

23.30

22.68

20.85

20.35

Carbon C

75.25

74.72

69.26

64.84

69.28

Nitrogen N2

1.22

0.76

8.06

12.90

1.41

10.37

1.22

--

Oxygen 02

--

Total

100.00

100.00

100.00

100.00

100.00

Sp Gr (Air= 1.0)

0.610

0.636

0.600

0.630

0.697

HHV Btu/ft3*

1,129

1,116

1,000

974

1,073

Btu/lb

23,170

22,904

21,800

20,160

20,090

Fuel lb/10,000 Btu

0.432

0.437

0.459

0.496

0.498

Theoretical Air lb/10,000 Btu

7.18

7.18

7.50

7.19

7.18

Total Moisture lb/10,O00 Btu

0.915

0.917

0.971

0.933

0.911

*At 60 degree F and 30 in. Hg

3-2

Previous Page

Previous Page