TM 5-815-1/AFR 19-6

made among the different reduction techniques. This

(3) Local market demand for recovered sulfur,

section shows how a rational basis can be utilized to

(4) Plant design limitations and site charac-

determine the best method.

teristics,

b. Boiler modification. This technique is useful in

(5) Local cost and availability of chemicals, util-

reducing SOx emissions by 0 to 6% depending upon

ities, fuels, etc.,

the boiler. For industrial boilers operating above 20%

(6) Added energy costs due to process pumps,

excess-air the use of proper control equipment or low

reheaters, booster fans, etc.

excess-air combustion will usually reduce emissions by

10-4.

Sample problems.

4 to 5%. If the operating engineer is not familiar with

boiler optimization methods, consultants should be uti-

The following problems have been provided to

lized.

illustrate how to determine the maximum fuel sulfur

c. Fuel substitution. This method can be used for

content allowable to limit SO emission to any

almost any percent reduction necessary. Availability

particular level.

and cost of the fuel are the major factors to be consid-

a. Approximately 90 to 97 percent of fuel sulfur is

ered. Fuels can be blended to produce the desired sul-

fur input. Care must be taken, however, so that the ash

This means that for every lb of sulfur in the fuel,

produced by the blending does not adversely affect the

approximately 2 lbs of sulfur oxides will appear in the

boiler by lowering the ash fusion temperature or caus-

stack gases. (The atomic weight of oxygen is that of

ing increased fouling in the convection banks.

sulfur.) Since most of the sulfur oxides are in the form

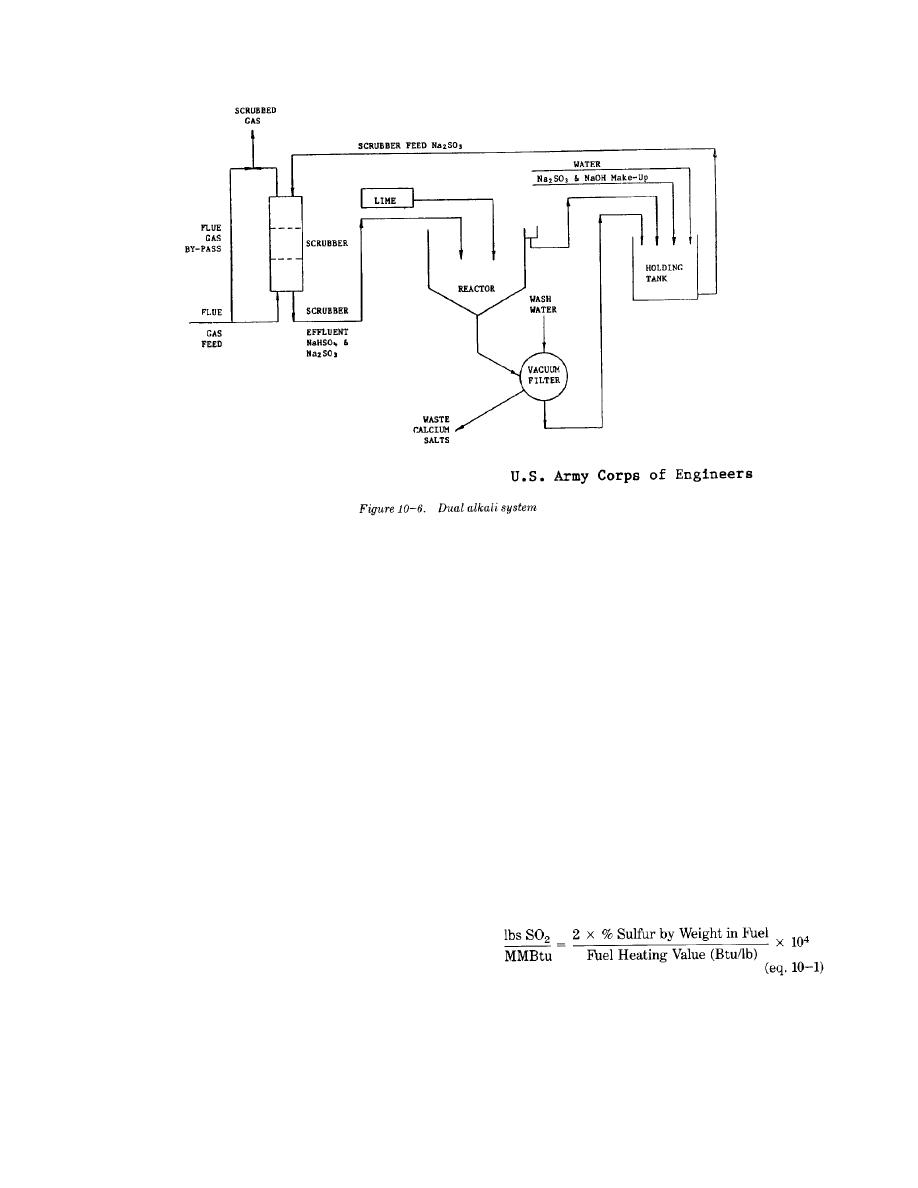

d. Flue-gas desulfurization. Various systems are

of SO2, emissions regulations are defined in these units.

available for flue-gas desulfurization. Some of these

To estimate maximum probable SO2 emissions, the fol-

systems have demonstrated long term reliability of

lowing equation applies:

operation with high SOx removal efficiency. Lime/lime-

stone injection and scrubbing systems have been most

frequently used. It must be recognized that each boiler

control situation must be accommodated in the overall

system design if the most appropriate system is to be

b. Assume a fuel-oil burning boiler must limit emis-

installed. The selection and design of such a control

sions to .35 lbs/MMBtu. What is the maximum allowa-

system should include the following considerations:

ble sulfur content if No.6 Residual fuel-oil is to be

(1) Local SO2 and particulate emission require-

used?

ments, both present and future,

(1) From table 10-3, Typical Analysis of Fuel-Oil

(2) Local liquid and solid waste disposal regula-

Types, an average heating value of 18,300

tions,

10-9

Previous Page

Previous Page