TM 5-815-1/AFR 19-6

gen contributes more to NOx formation at higher tem-

peratures.

11-3.

NOx reduction techniques

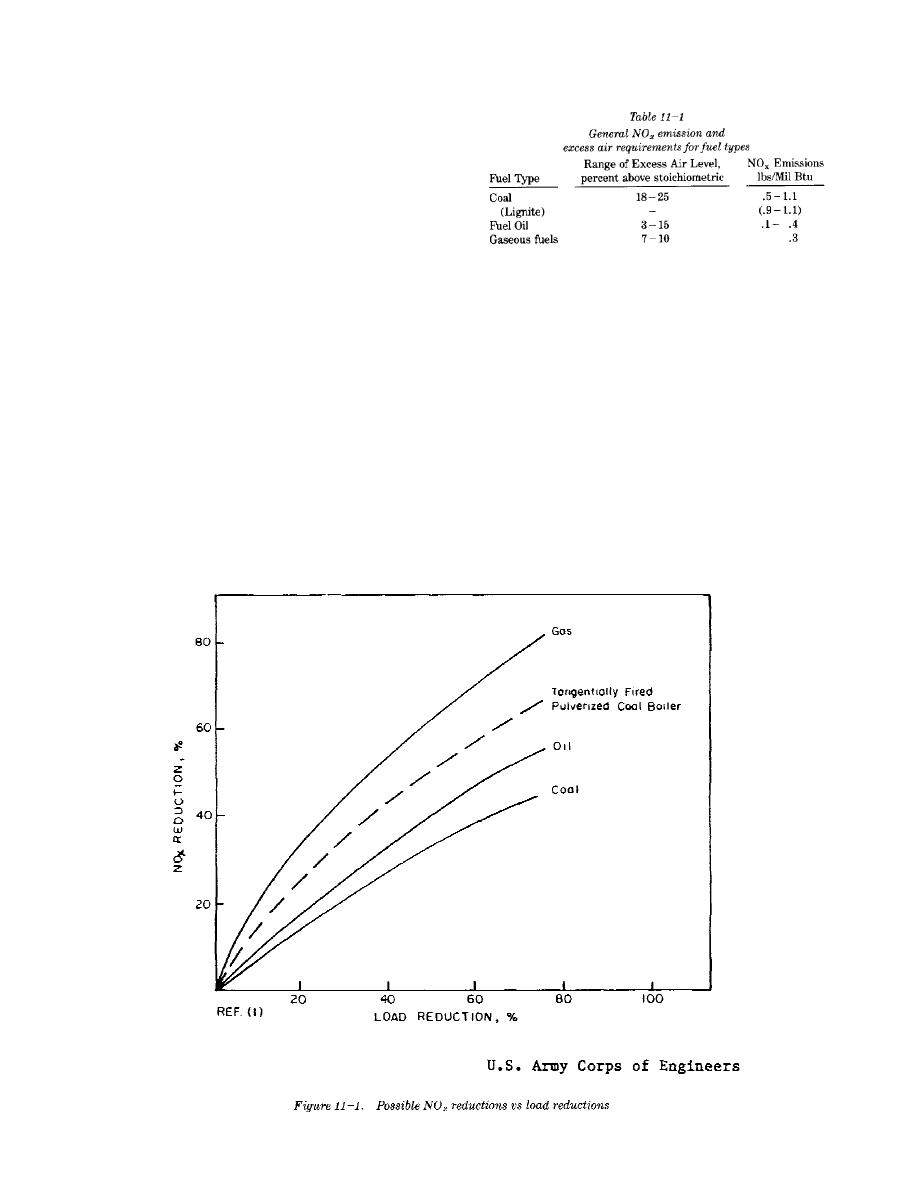

a. Fuel selection. Reduction of NOx emissions may

be accomplished by changing to a fuel which decreases

the combustion excess air requirements, peak flame

temperatures, and nitrogen content of the fuel. These

changes decrease the concentration of oxygen and

(3) Changing from a higher to a lower NOx

nitrogen in the flame envelope and the rate of the NOx

producing fuel is not usually an economical

formation reaction.

method of reducing NOx emissions because

(1) The specific boiler manufacturer should be

additional fuel costs and equipment capital

consulted to determine if a fuel conversion

costs will result. For additional information

can be performed without adverse effects.

on fuel substitution, see paragraph 10-3. In

The general NOx reduction capability of

doing so, it should be noted that changing

initiating a change in fuel can be seen

from coal to oil or gas firing is not in

comparatively in table 11-1.

accordance with present AR 420-49.

(2) A consideration when comtemplating a

b. Load reduction. Load reduction is an effective

change in fuel type is that NOx emission

technique for reducing NOx emissions. Load reduction

regulations are usually based on fuel type.

has the effect of decreasing the heat release rate and

Switching to a cleaner fuel may result in the

reducing furnace temperature. A lowering of furnace

temperature decreases the rate of NOx formation.

necessity of conforming to a more strict

(1) NOx reduction by load reduction is illustrated

emission standard.

in figure 11-1. As shown, a greater reduction

11-2

Previous Page

Previous Page