TM 5-815-1/AFR 19-6

(2) The successful application of LEA firing to

in NO2 is attainable burning gas fuels because

they contain only a small amount of fuel-

any unit requires a combustion control system

bound nitrogen. Fuel-bound nitrogen

to regulate and monitor the exact

conversion does not appear to be affected by

proportioning of fuel and air. For pulverized

furnace temperatures, which accounts for the

coal fired boilers, this may mean the

lower NOx reductions obtained with coal and

additional expense of installing uniform

oil firing. Some units such as tangentially

distribution systems for the coal and air

fired boilers show as much as 25 percent

mixture.

decrease in NOx emissions with a 25 percent

(3) Low excess air firing is a desirable method of

load reduction while burning pulverized coal.

reducing NOx emission because it can also

(2) Although no capital costs are involved in load

improve boiler efficiency by reducing the

reduction, it is sometimes undesirable to

amount of heat lost up the stack. Con-

reduce load because it may reduce steam

sequently, a reduction in fuel combustion will

cycle efficiency.

sometimes accompany LEA firing.

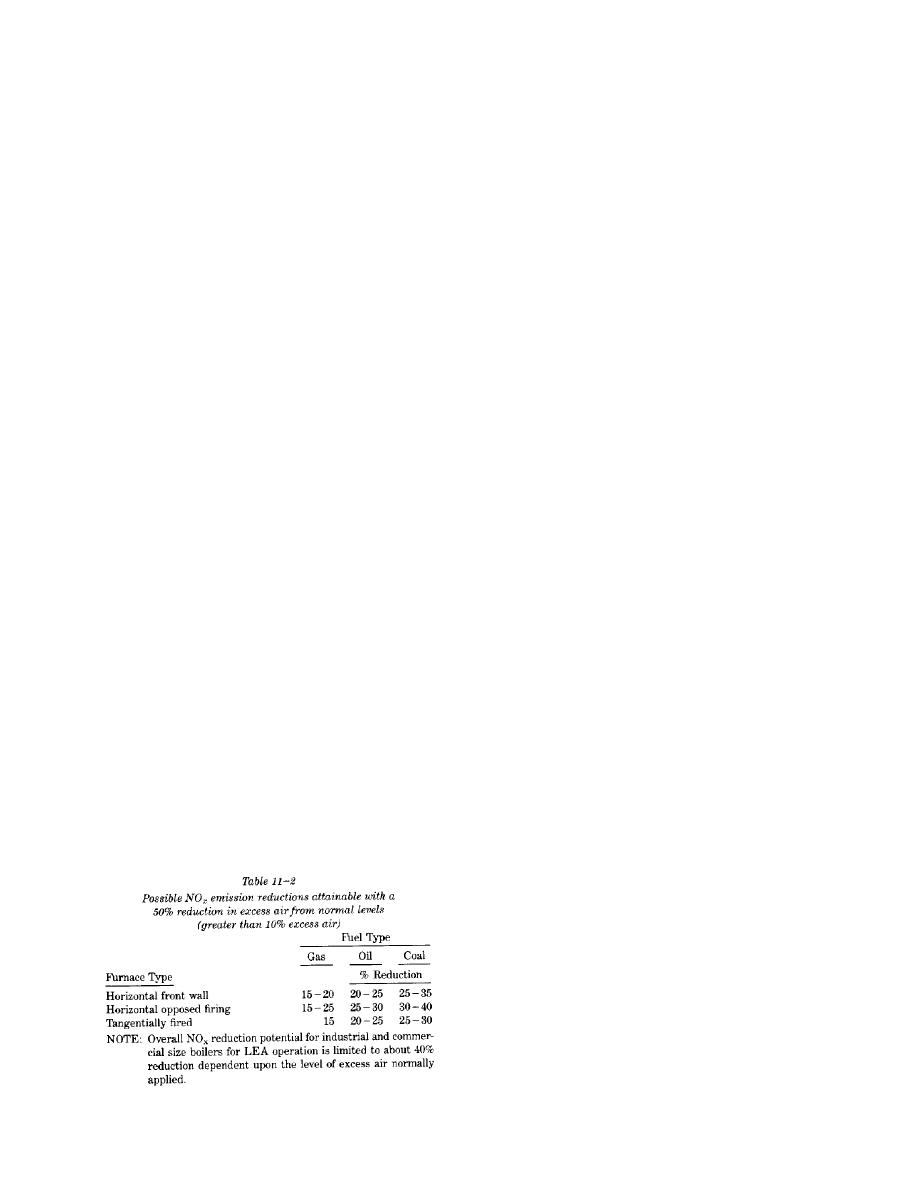

c. Low excess air firing (LEA). In order to complete

d. Low excess air firing with load reduction. NOx

the combustion of a fuel, a certain amount of excess air

emissions may be reduced by implementing a load

is necessary beyond the stoichiometric requirements.

reduction while operating under low excess air condi-

The more efficient the burners are in misting, the

tions (table 11-2). This combined technique may be

smaller will be the excess air requirement. A minimum

desirable in an installation where NOx emissions are

amount of excess air is needed in any system to limit

extremely high because of poor air distribution and the

the production of smoke or unburned combustibles;

resultant inefficient operation of combustible equip-

but larger amounts may be needed to maintain steam

ment. A load reduction may permit more accurate con-

temperature to prevent refractory damage; to complete

trol of the combustion equipment and allow reduction

combustion when air supply between burners is unbal-

of excess air requirements to a minimum value. NOx

anced; and to compensate for instrument lag between

reduction achieved by simultaneous implementation of

operational changes. Practical minimums of excess air

load reduction and LEA firing is slightly less than the

are 7 percent for natural gas, 3 to 15 percent for oil

combined estimated NOx reduction achieved by sepa-

firing, and 18 to 25 percent for coal firing.

rate implementation.

(1) Since an increase in the amount of oxygen

e. Two-stage combustion. The application of delayed

and nitrogen in a combustion process will

fuel and air mixing in combustion boilers is referred to

increase the formation and concentration of

as two stage combustion. Two-stage combustion can

NOx, low excess air operation is the first and

be of two forms. Normally it entails operating burners

most important technique that should be

fuel-rich (supplying only 90 to 95 percent of

utilized to reduce NOx emissions. A 50

stoichiometric combustion air) at the burner throat, and

percent reduction in excess air can usualy

admitting the additional air needed to complete

reduce NOx emissions from 15 to 40 percent,

combustion through ports (referred to as NO ports)

depending upon the level of excess air

located above and below the burner. There are no ports

normally applied. Average NOx reductions

to direct streams of combustion air into the burner

corresponding to a 50 percent reduction in

flame further out from the burner wall thus allowing a

excess air for each of the three fuels in

gradual burning of all fuel. Another form of two-stage

different boiler types are shown in table 11-2.

combustion is off-stoichiometric firing. This technique

Reductions in NOx emission sup to 62 percent

involves firing some burners fuel-rich and others air-

have been reported on a pulverized coal fired

rich (high percentage of excess air), or air only, and is

boiler when excess air is decreased from a

usually applied to boilers having three or more burner

level of 22 percent to a level of 5 percent.

levels. Off-stoichiometric firing is accomplished by

staggering the air-rich and fuel-rich burners in each of

the burner levels. Various burner configuration tests

have shown that it is generally more effective to

operate most of the elevated burners air-rich or air

only. Off-stoichiometric firing in pulverized coal fired

boilers usually consists of using the upper burners on

air only while operating the lower levels of burners

fuel-rich. This technique is called overfire air

operation.

(1) Two-stage combustion is effective in

reducing NOx emissions because: it lowers

the concentration of oxygen and nitrogen in

the primary combustion zone by fuel-rich

firing; it lowers the attainable peak flame

temperature by allowing for gradual

11-3

Previous Page

Previous Page