TM 5-815-1/AFR 19-6

combustion of all the fuel; and it reduces the

mixing accompanying the increased

amount of time the fuel and air mixture is

combustion air/ gas volume. Gas recirculation

exposed to higher temperatures.

does not significantly reduce plant thermal

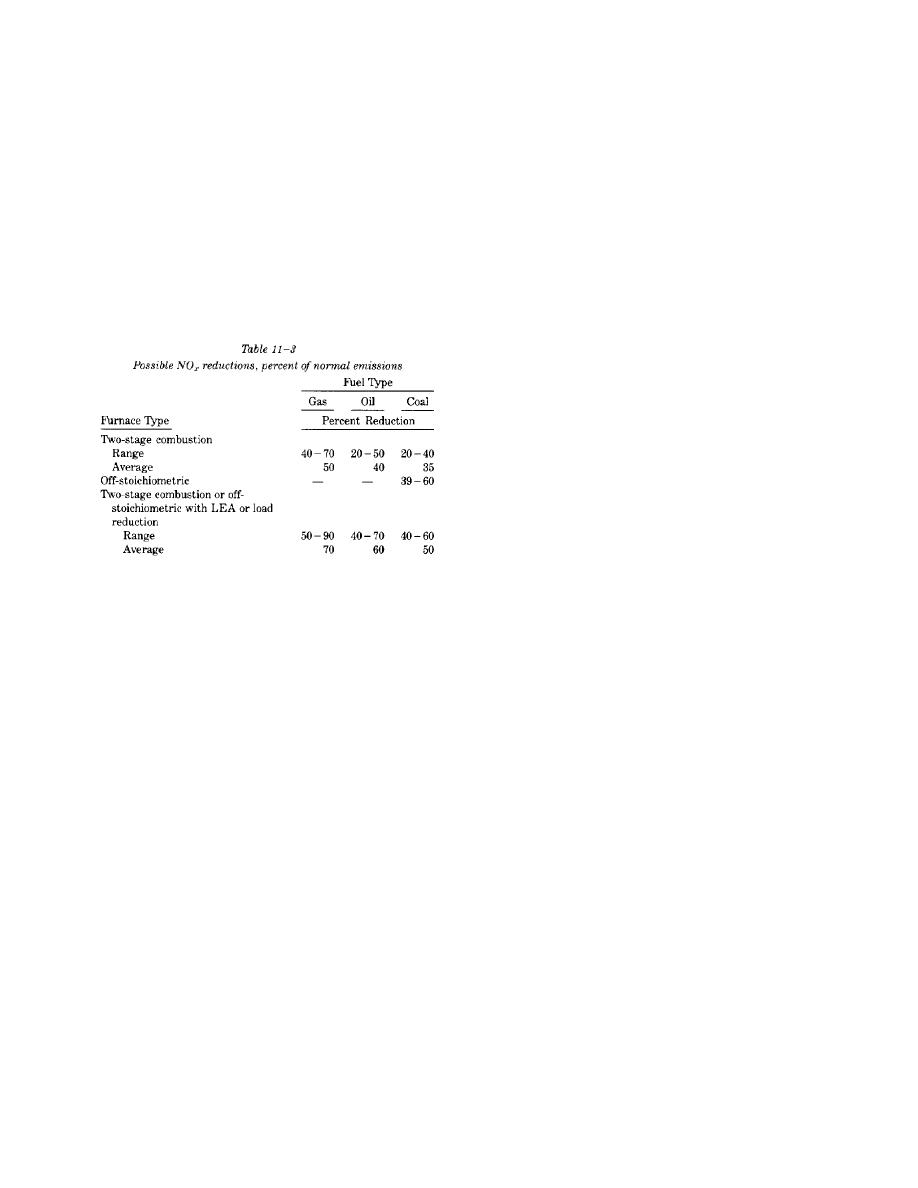

(2) The application of some form of two stage

efficiency but it can influence boiler

combustion implemented with overall low

operation. Radiation heat transfer is reduced

excess air operation is presently the most

in the furnace because of lower gas

effective method of reducing NOx emissions

temperatures, and convective beat transfer is

increased because of greater gas flow.

this combustion modification technique in

(2) The extent of the applicability of this

utility boilers are listed in table 11-3.

modification remains to be investigated. The

However, it should be noted that this

quantity of gas necessary to achieve the

technique is not usually adaptable to small

desired effect in different installations is

industrial boilers where only one level of

important and can influence the feasibility of

burners is provided.

the application. Implementing flue-gas

recirculation means providing duct work and

recycle fans for diverting a portion of the

exhaust flue-gas back to the combustion air

windbox. It also requires enlarging the

windbox and adding control dampers and

instrumentation to automatically vary flue-gas

recirculation as required for operating

conditions and loads.

h. Steam or water injection. Steam and water injec-

tion has been used to decrease flame temperatures and

reduce NOx emissions. Water injection is preferred

over steam because of its greater ability to reduce tem-

perature. In gas and coal fired units equipped with

standby oil firing with steam atomization, the atomizer

offers a simple means for injection. Other installations

f. Reduced preheat temperature. NOx emissions are

require special equipment and a study to determine the

influenced by the effective peak temperature of the

proper point and degree of atomization. The use of

combustion process. Any modifications that lower

water or steam injection may entail some undesirable

peak temperature will lower NOx emissions. Lower air

operating conditions, such as decreased efficiency and

preheat temperature has been demonstrated to be a

increased corrosion. A NOx reduction rate of up to 10

factor in controlling NOx emissions. However, reduced

percent is possible before boiler efficiency is reduced

preheat temperature is not a practical approach to NOx

to uneconomic levels. If the use of water injection

reduction because air preheat can only be varied in a

requires installation of an injection pump and attendant

narrow range without upsetting the thermal balance of

piping, it is usually not a cost-effective means of

the boiler. Elimination of air preheat might be expected

reducing NOx emissions.

to increase particulate emissions when burning coal or

oil. Preheated air is also a necessary part of the coal

11-4.

Post combustion Systems for NOx

pulverizer operation on coal fired units. Jn view of he

reduction.

penalties of reduced boiler efficiency and other disad-

vantages, reduced preheat is not a preferred means of

a. Selective catalytic reduction (SCR) of NOx is

lowering NOx emissions.

based on the preference of ammonia to react with NO,

g. Flue-gas recirculation. This technique is used to

rather than with other flue-gas constitutents. Ammonia

lower primary combustion temperature by recirculating

is injected so that it will mix with flue-gas between the

part of the exhaust gases back into the boiler com-

economizer and the air heater. Reaction then occurs as

bustion air manifold. This dilution not only decreases

this mix passes through a catalyst bed. Problems

peak combustion flame temperatures but also

requiring resolution include impact of ammonia on

decreases the concentration of oxygen available for

downstream equipment, catalyst life, flue-gas

NOx formation. NOx reductions of 20 to 50 percent

monitoring, ammonia availability, and spent-catalyst

have been obtained on oil-fired utility boilers but as yet

disposal.

have not been demonstrated on coal-fired units. It is

b. Selective noncatalytic reduction (SNR) Ammonia

estimated that flue gas recirculation has a potential of

is injected into the flue-gas duct where the temperature

decreasing NOx emissions by 40 percent in coal-fired

favors the reaction of ammonia with NOx in the flue-

units.

gas. The narrow temperature band which favors the

(1) Flue gas recirculation has also produced a

reaction and the difficulty of controlling the tem-

reduction on CO concentrations from normal

perature are the main drawbacks of this method.

operation because of increased fuel-air

11-4

Previous Page

Previous Page