UFC 3-430-07

24 July 2003

including Change 1, Jan 2004 and Change 2, March 2005

Notes:

1.

Additionally, MUSE boilers and other portable boilers are to be inspected externally and

internally and certified each time they are relocated from one activity to another. MUSE steam coil type

boilers are exempt from annual inspections while in dry or wet lay-up.

2.

All manhole and handhole gaskets must be replaced after application of the strength test

unless they are of the non-compressible steel type.

/2/

3.2

UNFIRED PRESSURE VESSELS. Inspection and test frequencies for

unfired pressure vessels are as shown in Tables 3-2, 3-3, or 3-4, as applicable.

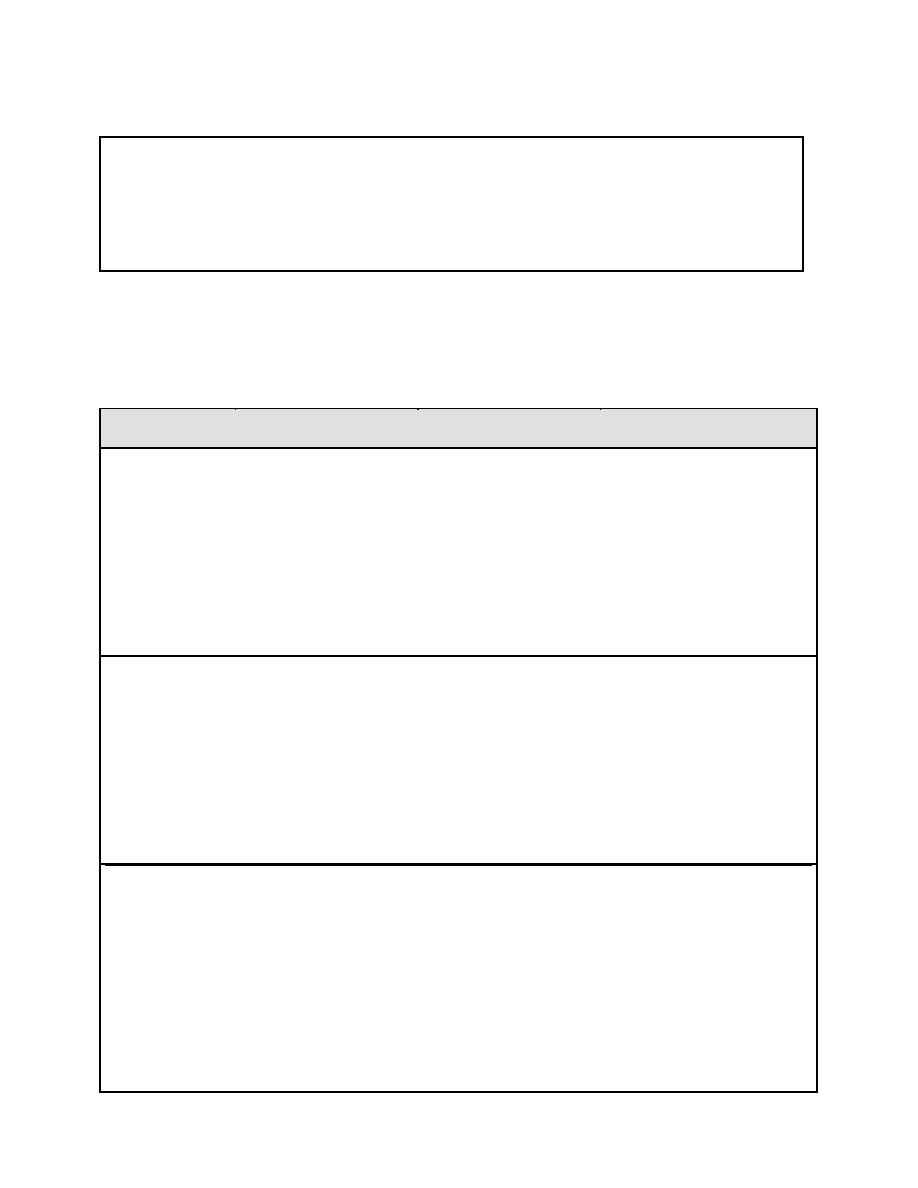

\ Table 3-2 Inspection and Test Frequencies - Unfired Pressure Vessels (UPVs)

Item

Internal Inspection

External Insp. &

Hydrostatic Test

Operational Test

Pressure Vessels

Every 3 years or more

After repair or alteration of

Every 3 years or more

&

frequently as determined

pressure parts. Additional

frequently as determined

Heat Exchangers

by procedures in the

times at the discretion of the

by procedures in the

(15 to 250 psig

NBBI Code for vessels

inspector.

NBBI Code for vessels

MAWP)

subject to corrosion.

subject to corrosion.

After any repair or

After any repair or

alteration of pressure

alteration of pressure

parts.

parts. Inspection must

For LPG see Table 3-3.

include test and

calibration of safety

valves and pressure and

temperature gages.

Pressure Vessels

Every 3 years or more

Every 3 years or more

Every 6 years of service. If

&

frequently as determined

frequently as determined

inspection shows no sign of

Heat Exchangers

by procedures in the

by procedures in the

corrosion, the test may be

(greater than 250

NBBI Code for vessels

NBBI Code for vessels

deferred until the next

psig MAWP)

subject to corrosion.

subject to corrosion.

inspection, but must be tested

After any repair or

After any repair or

at least every 12 years.

alteration of pressure

alteration of pressure

After any repair or alteration

parts.

parts. Inspection must

of pressure parts. Additional

For LPG see Table 3-3.

include test and

times at the discretion of the

calibration of safety

inspector.

valves and pressure and

temperature gages.

Notes:

1.

Test frequencies and inspections may be increased at the discretion of the inspector or owner if

the UPV is subjected, by the nature of its service, to an accumulation of deposits or thermal or

mechanical stresses that could affect the integrity of the vessel.

2.

A hydrostatic pressure test not to exceed 1.5 times the MAWP for BPVC ASME Section VIII

Division 1 vessels and 1.25 times the MAWP for BPVC ASME Section VIII Division 2 vessels may be

substituted for the internal inspection.

3.

If the tube bundle of the heat exchangers is a higher pressure than the shell, both sides of the

heat exchanger must be hydrostatically tested.

4.

Unfired pressure vessels are to be inspected externally and re-certified anytime they are

relocated or moved. It is the activity's responsibility to inform the inspector of the move. For UPVs

designed and built to be portable, reinspections are not required after a move as long as the vessel does

not leave the base. The inspector will indicate the UPV is "portable" on all appropriate reports. Once a

11

Previous Page

Previous Page