UFC 3-430-07

24 July 2003

including Change 1, Jan 2004 and Change 2, March 2005

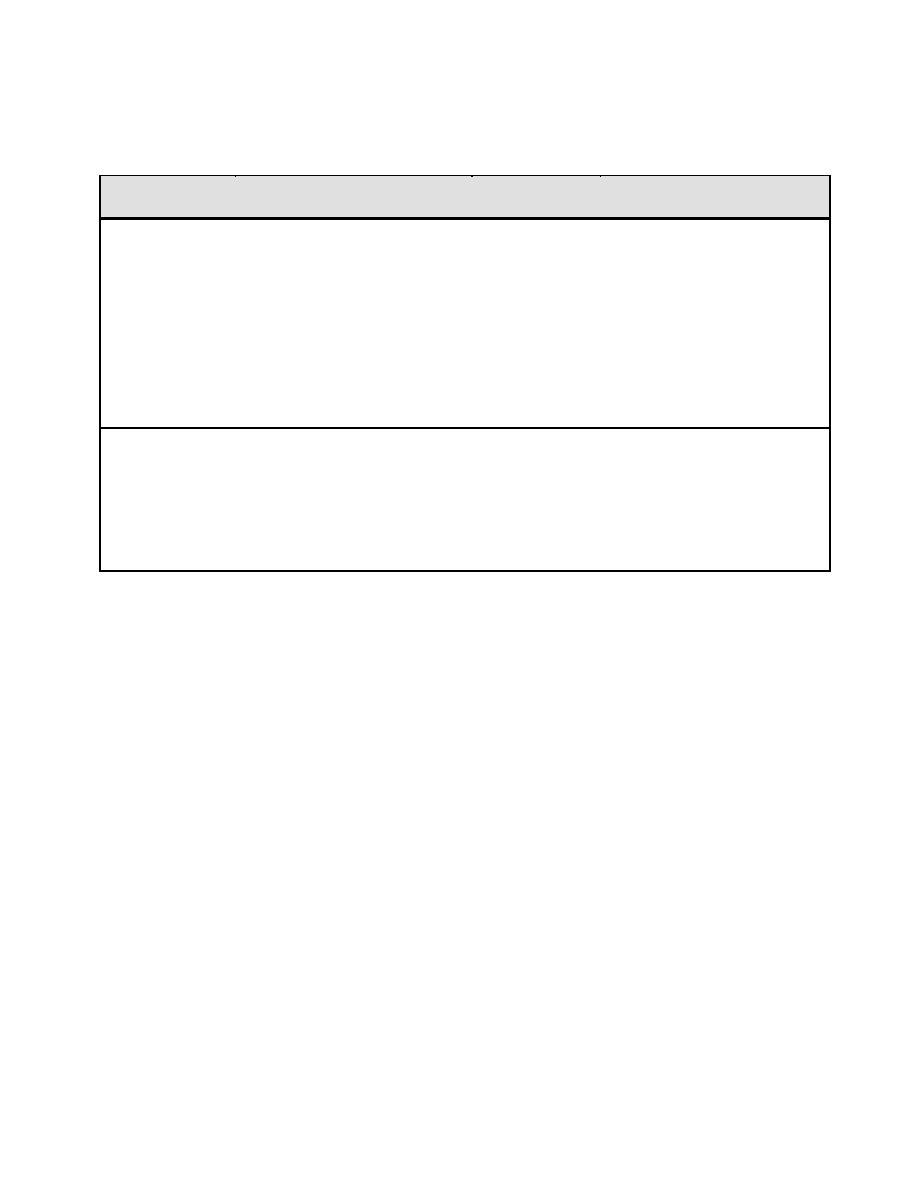

\ Table 3-4 Inspection and Test Frequencies - Deaerators

Item

Internal Inspection &

External

Hydrostatic Test

Operational Test

Inspection

Every 3 years.

Tightness test every 6 years.

Deaerators

Every 6 years. After any

After any

Strength test after repair or

repair or alteration of

repair or

alteration of pressure parts.

pressure parts. Inspection

alteration of

Additional times at the

must include test and

pressure parts.

discretion of the inspector.

calibration of safety valves

and pressure and

temperature gages.

Inspection must include test

and calibration of safety

valves and pressure and

temperature gages.

Notes:

1.

In addition to the safety inspection, the operators of the vessel should periodically examine and test

the deaerators for proper operation. Improperly operating deaerators result in excessive corrosion and

cracking. The key to satisfactory operation is proper water treatment.

2.

Scheduling of deaerator inspection at many facilities requires scheduled downtime for many heating

and power plants. The activity should prepare to hire a company specializing in deaerator evaluations to

determine if the vessel is repairable if cracking or excessive corrosion is found during the visual inspection.

Options to lease deaerators prior to the inspection should be considered.

/2/

16

Previous Page

Previous Page