UFC 3-440-01

14 June 2002

model can still be used with a correction for propylene glycol, since such use will be

conservative. In addition, although these flows are often laminar, they are usually near

the laminar/turbulent transition point where pipe bends and flow restrictions can easily

trip laminar flow to turbulent. The design operating temperature of the collector loop

should be between 60 and 90 degrees F (15 and 32 degrees C), with the 60 degree F

(15 degrees C) value preferred because it is the lowest temperature (thus highest

viscosity and pressure drop) that steady-state operation could be expected. If a higher

temperature is to be used, the designer should apply the standard temperature

corrections for water before correcting for the use of propylene glycol.

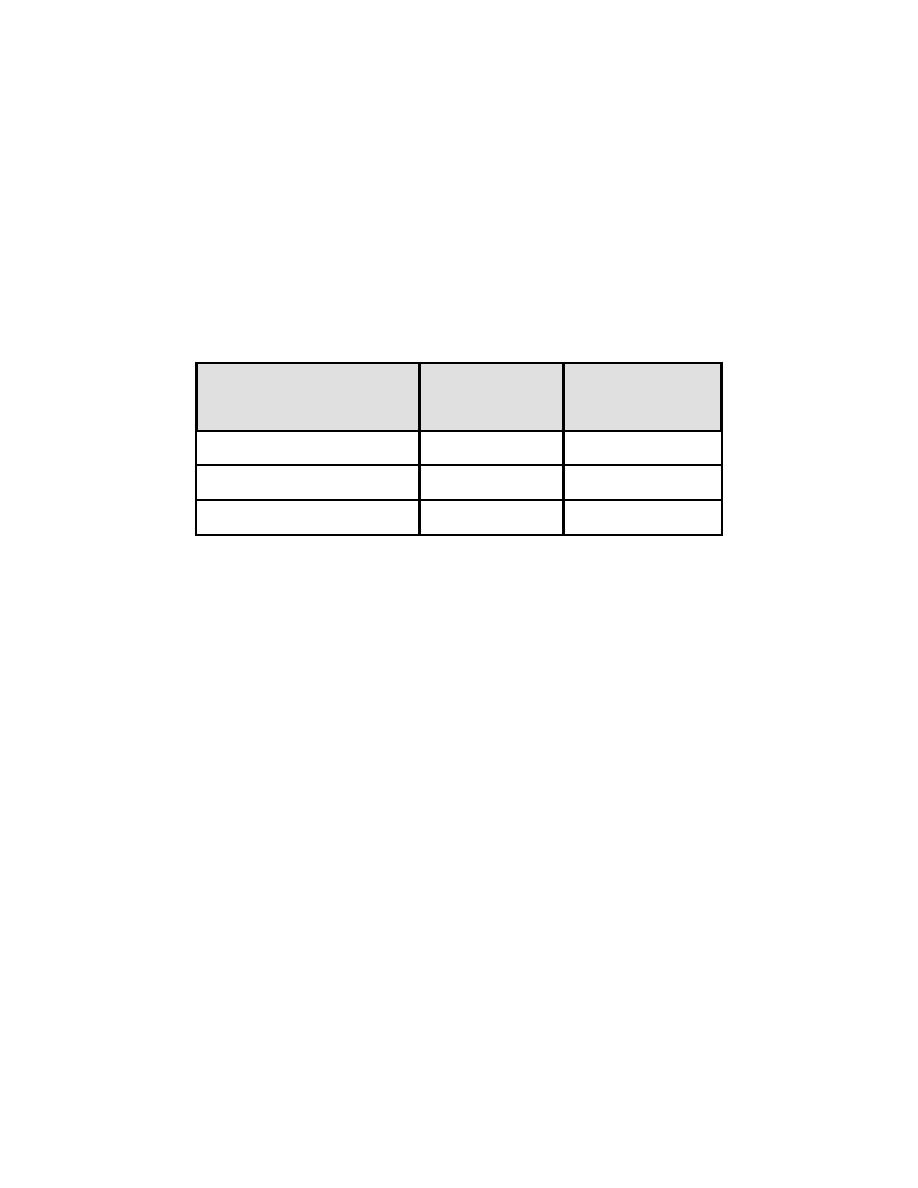

Table 4-1. Pressure Drop Corrections

Heat Transfer Fluid

Pressure Drop

Velocity Correction

(Percent Propylene-Glycol)

Correction

(Estimated)

50 (closed loop)

x 1.4

x 0.8

30 (closed-loop)

x 1.2

x 0.9

0 (direct circulation)

(x 1.0)

(x 1.0)

4.2.2.6.3

Flow Balancing. Flow balancing of the main array supply manifold and its

associated risers can be accomplished using the "30 percent rule" cited earlier. To

begin, the pressure drop in the risers must be known - this usually means that the flow

balancing calculations start with the collector banks since the pressure drop across a

collector bank can be considered to be the same as the pressure drop across a single

collector. The flow rates required in all branches must also be known. A first guess of

the manifold internal diameter should be made. Each section of manifold between the

risers will have a different flow rate, and the pressure drop associated with each flow

rate and pipe length must be determined. The sum of each of these pressure losses

will be the pressure drop along the entire manifold. This pressure loss is compared to

the pressure drop across the riser (in this case, the row or bank manifold), and if it is

less than 0.3 (around 0.1 is preferred) of the bank manifold pressure drop, the

proposed diameter is acceptable from a flow balancing point of view. This assumption

neglects the additional pressure loss associated with the bank manifold and its

connections, and is thus conservative. If the proposed diameter is too small (or too

large), another guess should be made. Figure 4-6 and Figure 4-7 provides an example

of sizing a manifold to provide balanced flow while satisfying both the 30 percent rule

and the 5 ft/s (1.5 m/s) velocity restriction.

4-10

Previous Page

Previous Page